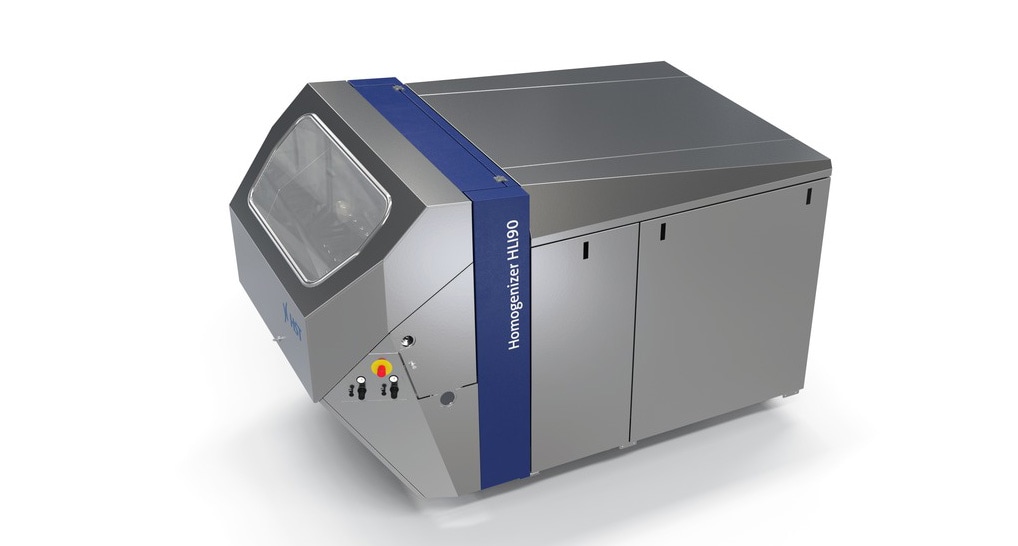

In 2019, HST successfully launched its most powerful high-pressure homogenizer, the 355-kW HL8, which can handle 55,000 liters per hour at a homogenizing pressure of 200 bar. And now, the HLI series has been added to complement the proven HL range. These new 55 to 90-kW systems can process up to 13,000 liters per hour at 200 bar. At launch time, three models are available: HLI55, HLI75, and HLI90, all in the same configurations as the HL series and including an option that fulfils the European Union’s ATEX (Equipment for potentially explosive atmospheres) Directives. Additional models for the lower output range to 45 kW (for instance for 5,000 liters per hour at 200 bar) are currently in development. The systems in the new series each consist of a three-piston high-pressure pump with a homogenizer valve at the outlet.