Market demands have changed since Evoguard started delivering its valve control head with its characteristic stainless-steel housing back in 2013/2014. That is why, in 2019, the company began developing a new product generation in an updated design that more closely matches that of the Evoguard valve series itself. Another key objective in evolving the control head was to make it more robust and more versatile.

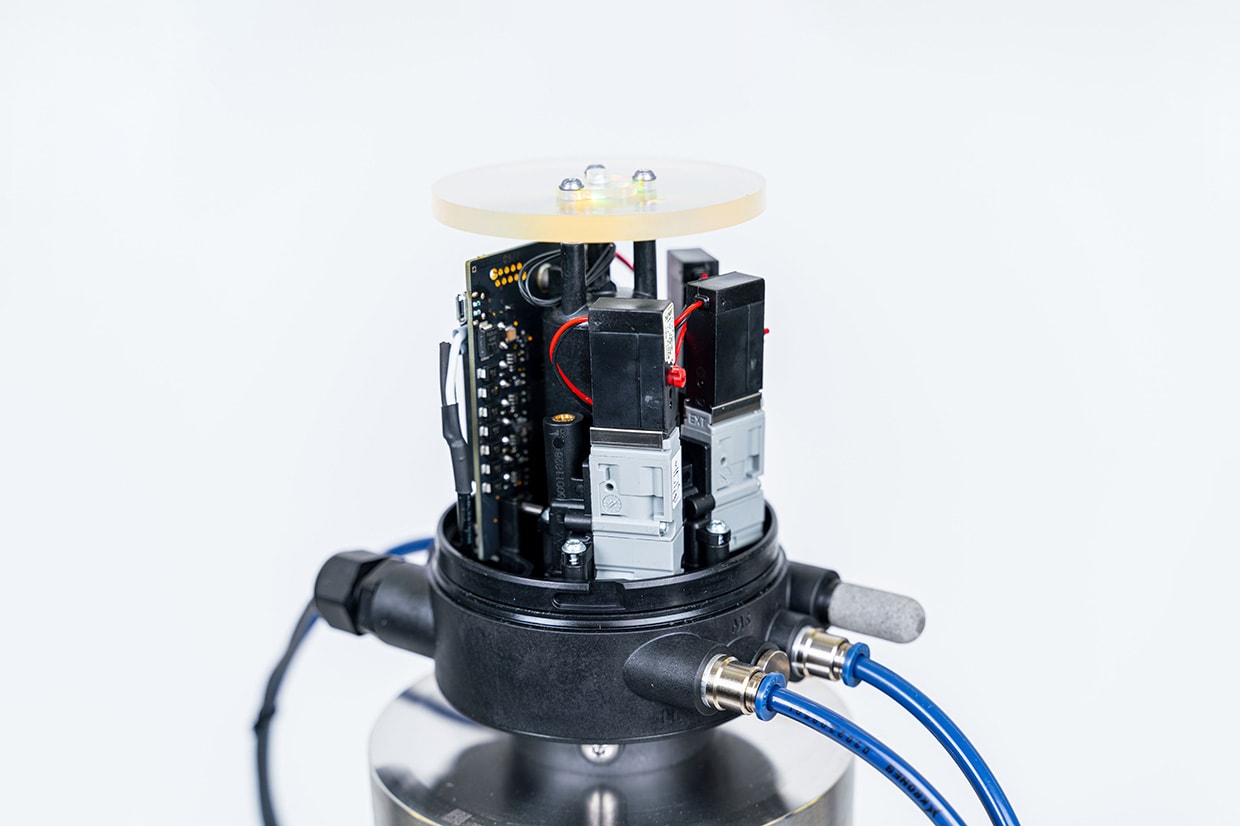

One of the most important functions of the new valve control head is to indicate the valve’s switching and maintenance status – and an optical signal provides just that, at a glance. It was also especially important to the industrial designers that the new control head fit seamlessly into the broad range of Evoguard valves and be capable of universal application. A new adaptation ensures that both the electrical and pneumatic supply lines can remain connected during maintenance work.