Now the beverage producer has placed an order with Krones for Lines 3 and 4, one PET line for CSDs and one for still water. With that, the company fills all its products exclusively on lines from Krones. Commissioning started end of 2021.

Scope of delivery

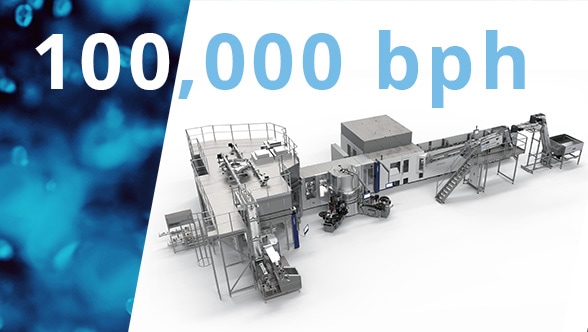

- Bottling line for still water, rated at 40,000 PET containers per hour, including a blow-moulder/filler block with Contiform 3 Speed and Hydrofill

- PET line for CSDs, rated at 60,000 containers per hour, including a blow-moulder/filler block with Contiform 3 Speed and Modulfill VFS, plus an integrated Contiflow mixer