Our authors

-

Pia BrunschCorporate Communications

Pia BrunschCorporate Communications

PR -

Angelika KremplCorporate Communications

Angelika KremplCorporate Communications

PR -

Julia LesererCorporate Communications

Julia LesererCorporate Communications

PR -

Peter MörtlCorporate Communications

Peter MörtlCorporate Communications

PR -

Lisa PfefferCorporate Communications

Lisa PfefferCorporate Communications

PR -

Gitta RohlingExternal copywriter

Gitta RohlingExternal copywriter -

Christine RüthExternal copywriter

Christine RüthExternal copywriter -

Helena SchaefferCorporate Communications

Helena SchaefferCorporate Communications

PR -

Sophie SchwinghammerCorporate Sustainability

-

Maria SeywaldCorporate Communications

Maria SeywaldCorporate Communications

Social Media -

Markus StettnerCorporate Communications

Markus StettnerCorporate Communications

PR -

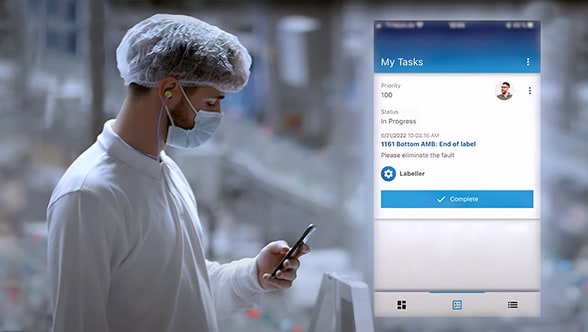

Patricia ThumMarketing and Corporate Communications

Patricia ThumMarketing and Corporate Communications

Syskron Gmbh -

Aaron WesolowskiMarketing and Corporate Communications

Aaron WesolowskiMarketing and Corporate Communications

Krones Inc., USA