Cooling energy for all industrial sectors

Whether in the production of beverages or food, the processes in the chemicals or pharmaceuticals industry or in the operation of data centres: Almost every industrial sector needs cooling energy. And this is exactly what the Krones VapoChill cooling tower provides.

It combines the Krones know-how from plant engineering for the beverage industry with the knowledge of thermal processes. The result: a modular series which sets a new standard with regard to the efficiency of process water cooling. And compared to conventionally operated cooling towers, the VapoChill series saves a large amount of process water.

At a glance

- Scalable design capable of covering cooling requirements from 50 to 2,000 kW

- Design based on customer-specific cooling requirements and local climate conditions

- Fast “plug and play” installation

- Stainless steel housing and components with a long service life

The VapoChill series at a glance

The VapoChill benefits from Krones accumulated expertise in the field of engineering. Even though the method of operation is designed to precisely meet the requirements of the beverage industry, it can be easily transferred to other industries.

Method of operation: open-circuit cooling tower

The process water is cooled using ambient air: when the air and water come into contact with one another, a part of the water evaporates. This process takes energy from the rest of the water and cools it down.

- High energy output in a small footprint

- Low electric power

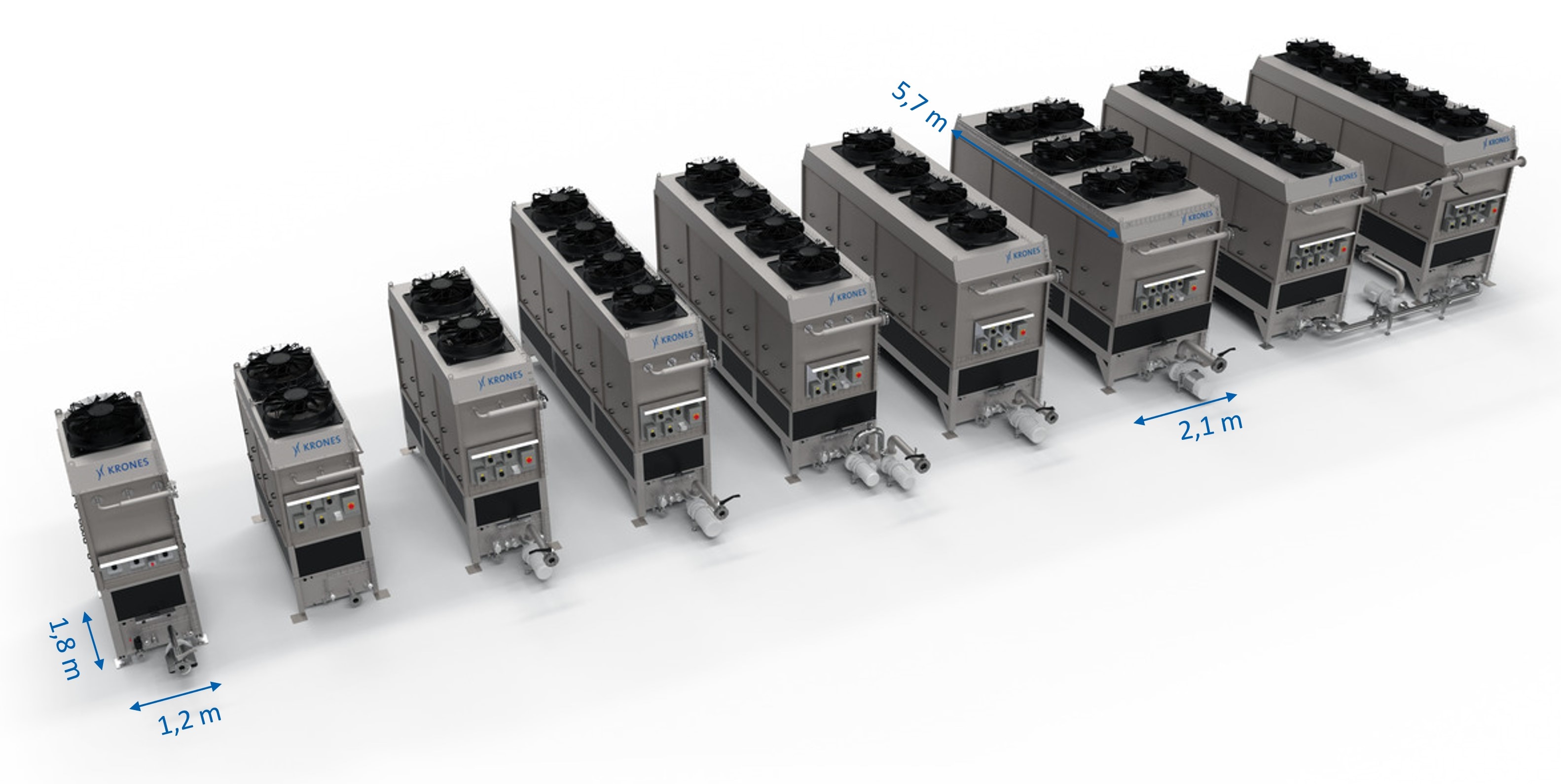

Eight different variants

- Cover cooling capacities of between 50 and 2,000 kW

- Dimensions:

- Width: 1.2 to 2.1 metres

- Length: 1.8 to 5.7 metres

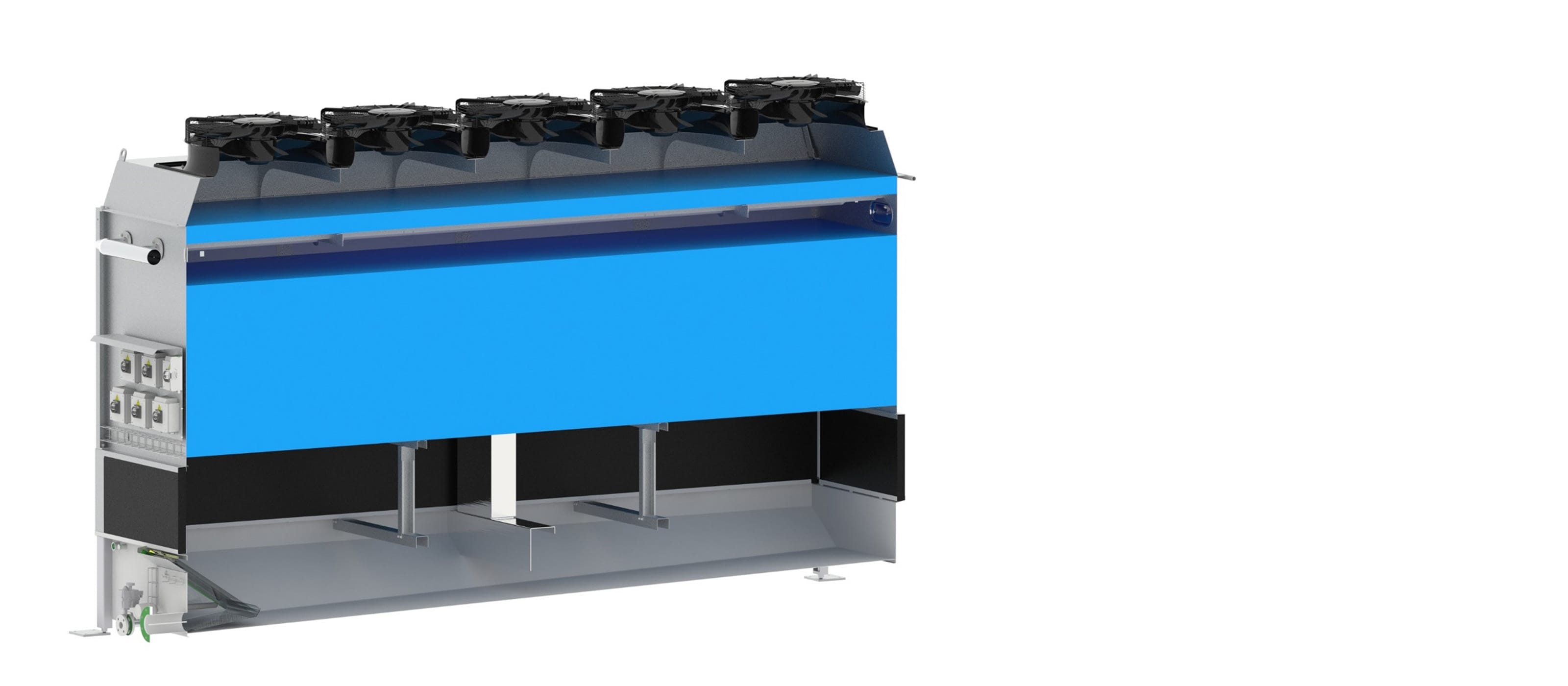

Structure of the cooling tower

Inlet louvres

cross-fluted fills

- Continually resistant at up to 70 °C (briefly even up to 80 °C)

- variable heights available

- High efficiency (240 m² exchange surface per m³)

- Optional: Cross-fluted fills and droplet separators with biocide

Droplet separators

- Continually resistant at up to 70 °C (briefly even up to 80 °C)

- certified by EUROVENT

Detachable sieve forpump protection

Accessible from the outside: cleaning is possible during operation

Intake stub (customer-specific)

Drain connection piece (flap optional)

Filling connection and overflow device

Maintenance switch

Spraying system

- Variable arrangements for the optimum spraying of the cross-fluted fills with only a low pre-pressure at the nozzles (max. 0.6 bar)

- 5 to 25 m³/m² per hour possible

Fans

- Axial EC fans with up to 30 percent lower energy consumption in full-load operation

- Infinitely adjustable speed control possible

- Specifically designed for use in cooling towers

Flexible modular design

All sizes:

- Are possible in AISI 304 or optionally in AISI 316L, stainless steel

- Can be combined as multi-cell cooling towers, to also reach high outputs for example.

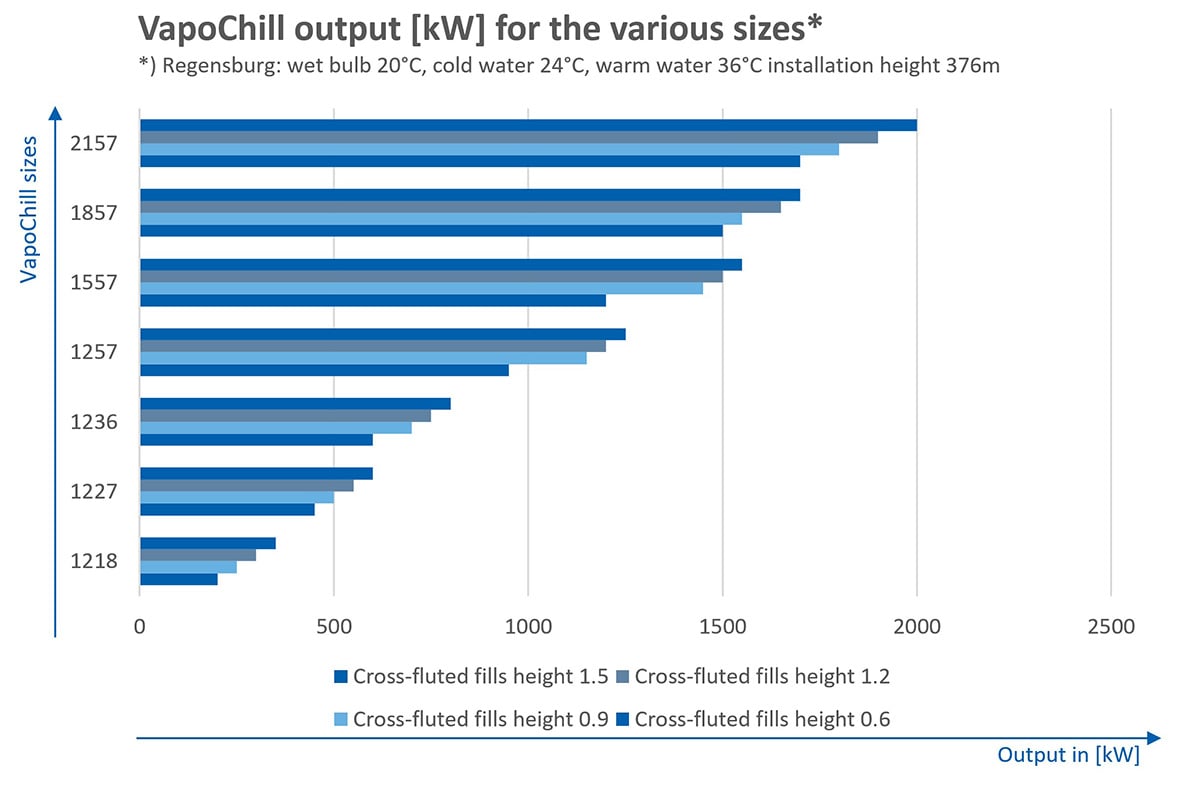

- Are available in four different cross-fluted fill heights (0.6, 0.9, 1.2 and 1.5 metres)

- Can be flexibly adapted through component selection (Nozzle selection, Numer of fans, ...)

Individual design entirely in line with your requirements

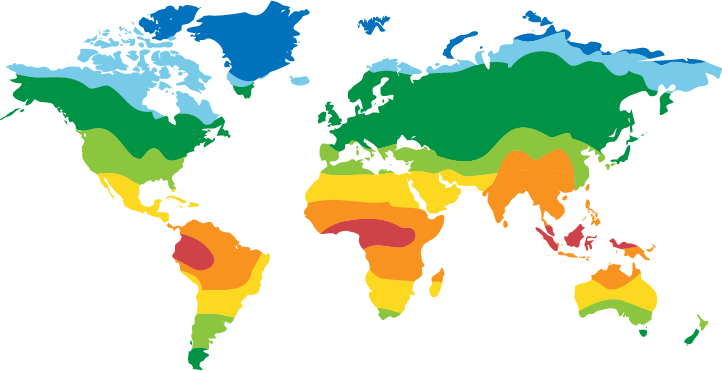

When designing your system, it goes without saying that we take your individual process requirements, as well as the climatic and geographical data of the cooling tower’s future place of installation, into account – and thus adjust the VapoChill to precisely fulfil your needs.

Individual process and system parameters:

- Cooling capacity

- Cold and warm-water temperature

- Installation surface footprint and weight of the cooling tower

- Energy consumption

- Noise emissions

- Consideration of the investment costs and TCO

Climatic and geographical data:

- Air pressure/altitude

- Ambient air temperature

- Wet bulb temperature (from databases, from the system operator and Krones internal data)

Benefits to you

Low use of biocides

If cross-fluted fills with biocide are chosen, then the largest surface in the cooling tower will be protected against fouling because of microorganisms This option is also particularly characterised by its long operating times and lower biocide dosing quantities.

Flexible during output adjustments

There are four different cross-fluted fill heights for each size. Benefits to you: If you wish to increase the cooling capacity, it may suffice to start by exchanging the cross-fluted fills instead of the entire cooling tower. This keeps the footprint and costs low while increasing the cooling capacity.

Many-years of experience and turnkey expertise

As a systems supplier for the beverage industry, Krones has decades of experience in systems construction – and has now adapted it for its VapoChillseries. From Krones you will receive a customised complete package that, in addition to the cooling tower, can also include all of the other components and connections with quick availability.

Efficient, reliable dispatch and prompt commissioning

No matter which size you choose: Krones cooling towers are always split up into four modules and fit into a standard container for dispatch. This not only saves on transport costs, its modular construction also saves on the time needed for commissioning.

Best hygiene conditions

The unit is designed in accordance with “hygienic design” principles to achieve the best possible cleaning result with minimum staff requirements. The immersion pickled stainless steel housing also ensures that the cooling towers can be ideally installed outdoors. The AISI 316L variant can even be installed in coastal areas without further thought.

High resource efficiency

Speed-controllable fans with optimised efficiency (ɳ > 50 %) are already included in the standard scope of supply. These make it possible to achieve energy savings of up to 85 percent during operation (compared to conventionally operated cooling towers with asynchronous drives at changing cooling capacities).