Maximised automation

“But our paramount goal is to ensure that our lines, too, are run with a maximised degree of automation,” says Alberto Bertone. To achieve this, he has over the past two years had five new bottling lines from Krones installed.

- Three of these replaced relatively old lines with machines from various manufacturers, and have increased the output from what used to be 20,000 each to what is now 54,000 bottles an hour.

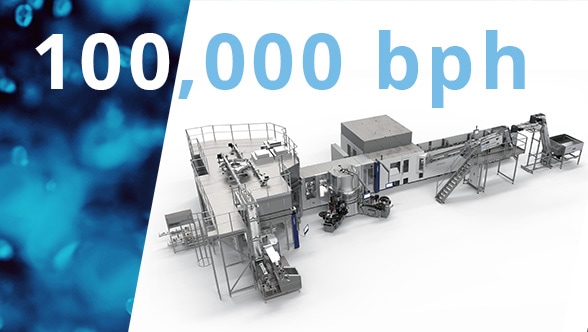

- The other two were additionally installed in order to upsize capacities still further, and to upgrade efficiency levels as well:

The lines’ tasks are clear: three of them fill exclusively still water in square 1.5-litre containers. This bottle type accounts for more than 70 percent of total sales, and, thanks to its shape, does not take up as much storage space as its cylindrical counterparts. Another 54,000-bph line handles just these cylindrical bottles, in sizes of 0.5, 1.0 and 1.5 litres, filling them with still and carbonated water. The fifth new line, the last of them, commissioned in August 2018, fills 0.5-litre bottles at a speed of 81,000 containers an hour.