Lautering with the Pegasus – high-quality worts and economical processes

Intelligent lautering technology

The lautering process must meet clear technological requirements: The separation of the mash must yield high-quality worts with a low proportion of solids.

And then there are the economical aspects: High brew rates are possible thanks to the fast process. Furthermore, it must also be possible to obtain almost all of the extract dissolved from the spent grains.

With the Pegasus C, the brewer uses a fully automatic lautering system which fulfils all of the requirements from a technological and economical viewpoint.

At a glance

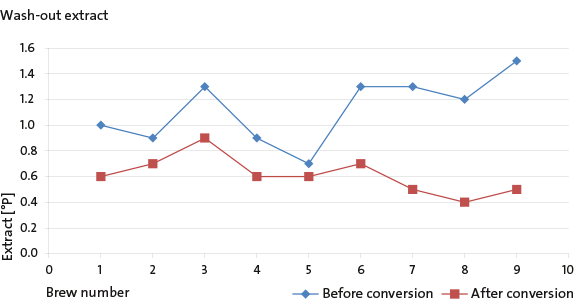

- High extract yields through efficient leaching of the spent grains during sparging

- Flow control with the Super-Trend lautering principle for quick and even lautering

- Optimum design of the raking device for an ideal cutting pattern

Your benefits

Extraction of high quality worts

The brewer achieves a maximum extract yield through design adjustments in source areas and the raking device.

Technology suitable for flexible use

The Pegasus can also be used for high-gravity brewing processes. Pegasus offers high flexibility in the selection of the type and quantity of raw materials thanks to the wide range offered by the specific false bottom load.

Lowest maintenance and operating costs

The cleaning costs can be kept at a very low level with just one CIP cleaning process required per week. In addition, a low media consumption is also possible compared to applications where a mash filter is used.

Automated process

Fully automatic production and cleaning processes offer maximum production reliability.