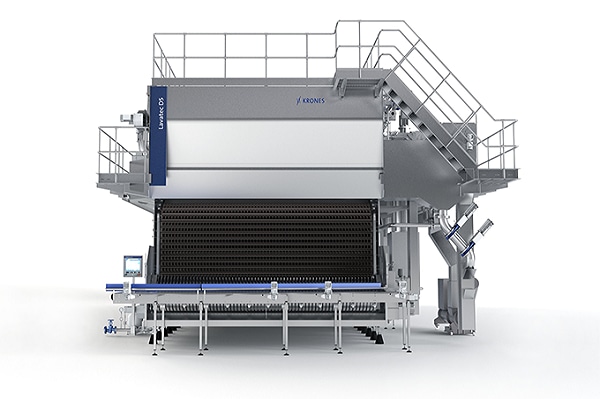

Double-end washers

Gives bottles a shiny appearance

As individual as the jobs they master: The Lavatec D and LavaClassic D double-end washers comprise a modular system containing freely combinable components.

Regardless of how you specifically design your machine: It will always impress with its perfect cleaning results andeconomical use of resources.

At a glance

- Freely combinable modular component system, individually arranged

- Economical consumption of resources through use of state-of-the-art-technologies (improved CO2 footprint)

- Different pre-treatment options –including special solutions such as sand and glass fragment removal

- Main drives with servo controller

- Easily accessible central pipe system

- Optimum accessibility thanks to user-friendly catwalk concept

- Optional: Microfiltration in the main caustic system for a lower use of

chemicals and higher machine availability - Process optimisation thanks to latest digital products

Individual machine concept for every output range

Thanks to their modular component system and individual technical configuration, double-end washers from Krones AG can meet any challenge. The LavaClassic and Lavatec series cover an output range of 10,000 to 144,000 bottles per hour. When doing so, the latest safety standards are always observed and the interfaces for a higher-level automation system integrated.

The reliable cleaning professional

- Straight forward bottle washer with proven technology

- Different pre-treatment and post-treatment zones for all requirements

- The right decision for a limited budget

The economical solution for water and energy management

- Meets the highest technical demands for effective and efficient cleaning

- Maximum pre-treatment and post-treatment

- Minimum operating costs

- Complete post-treatment area in “Clean Design”

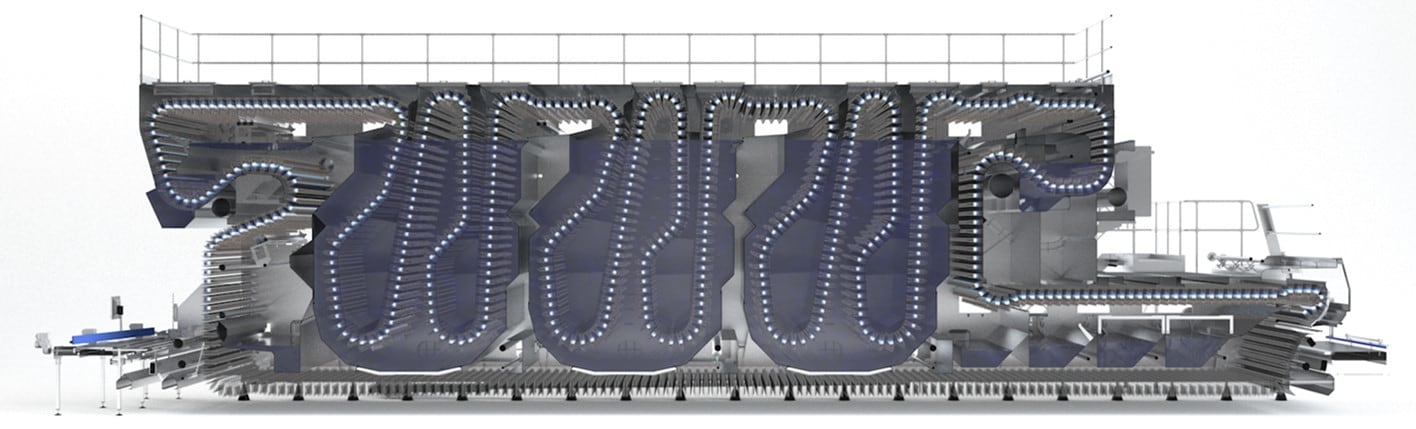

Layout of a double-end bottle washer

Post-treatment

- Bottle rinsing system with fresh water uses state of-the-art process technology to minimise fresh water consumption

Tubular heat exchanger

- Heat distribution via low-maintenance external tubular heat exchanger

Modular caustic tanks

- Single or double loops for the caustic tanks with individual temperature stages and optimised mechanical cleaning through interior spray cleaning

Modular pretreatment

- Efficient pre-washing and pre-heating ensures a long service life for the caustic and minimises the use of resources

Infeed

- Double-finger infeed with overload protection for highly efficient bottle infeed

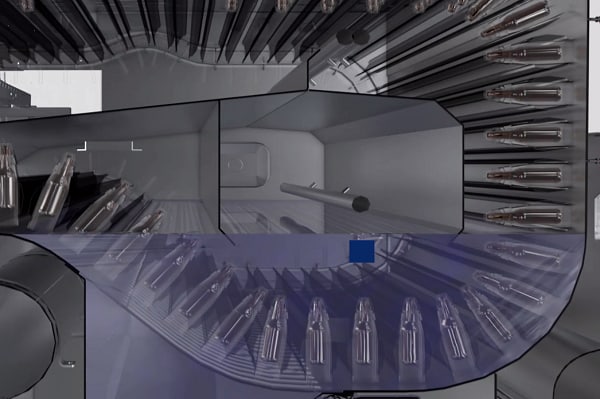

Clean Design for the most stringent hygiene demands

The revised clean-design concept also meets the highest demands on quality and hygiene. Thus, the machine itself shines with cleanliness!

Optimum access

- Reduced cleaning time

- Thanks to the easy-to-open access points and the optional automatic lifting windows, personnel demands for cleaning are low

Simple and thorough cleaning

- Bottom troughs mounted with an incline

- No dead corners in the shape of the basin

- Short drying times

- Zones can be cleaned quickly

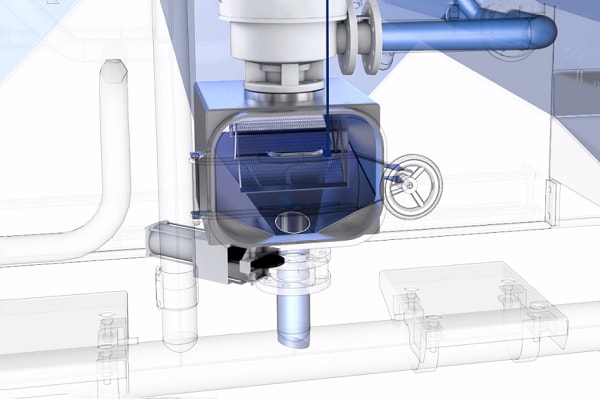

Self-cleaning pump sieves (For CD post-treatment only)

- Complete emptying of the pumps

- Low personnel requirements

- Short cleaning time

- Self-cleaning filter

Post-caustic fine filtration (For CD post-treatment only)

- Low dirt load

- Protection against fibre entrainment into the sensitive water zones

Benefits to you

Microbiologically up to date

The post-treatment section is designed in Clean Design. The double-end design provides spatial separation between contaminated and clean bottle flow. Together with our innovate filtration concepts, it thereby meets the highest hygiene demands.

Absolutely efficient

Thanks to the automatic filtration of contaminants, resources are used sparingly. At the same time, the modular machine layout can be individually customised to the bottle and label quality.

Sparing use of resources

The Krones bottle washer surprises with its economic water and energy budget. And it proves that you do not always need lots of chemicals to achieve highest hygiene standards.

Digitally up to date

The latest technology used on the touch-screen and in the PLC ideally equips our machines for the new age of digitalization. For this purpose, we offer a wide portfolio of digital products for the line and machine, as well as individual setting options directly on the touch-screen.

Operation made easy

All double-end bottle washers offer easy access to all components so that cleaning and maintenance can be performed as quickly as possible.

This is why the Lavatecseries is enviro-classified:

Energy efficiency

- Low consumption of thermal energy thanks to the use of insulation, regenerative heat transfer devices and lattice or

lightweight carriers - Economic water consumption thanks to optimised water routing, pressure regulation and fresh water cooling concepts

Environmental compatibility

-

Minimised water and lubricant consumption using innovative technologies