Our expert when it comes to beer filling in glass bottles

Clear plus points in terms of hygiene, change-over time and CO₂ consumption

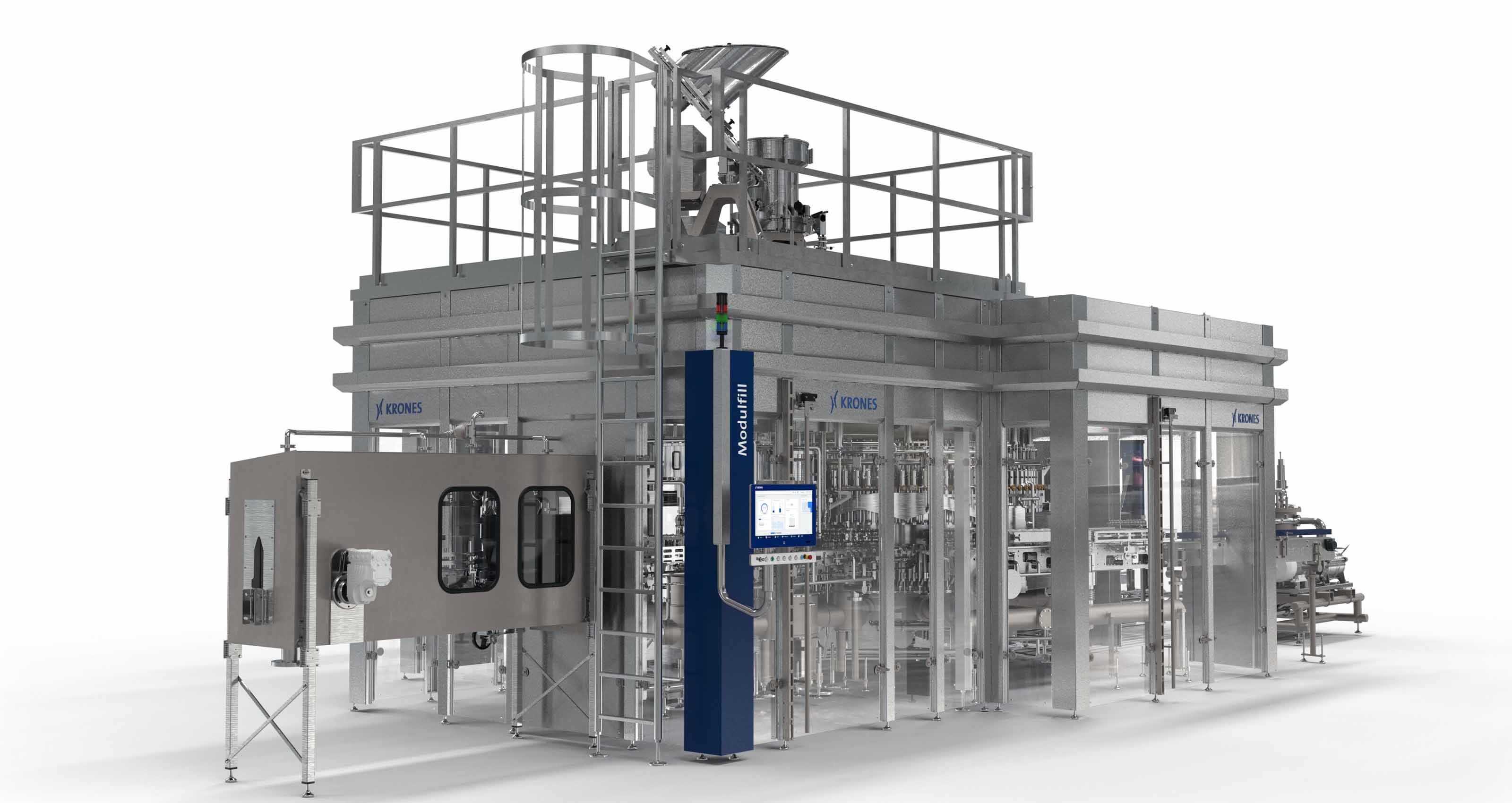

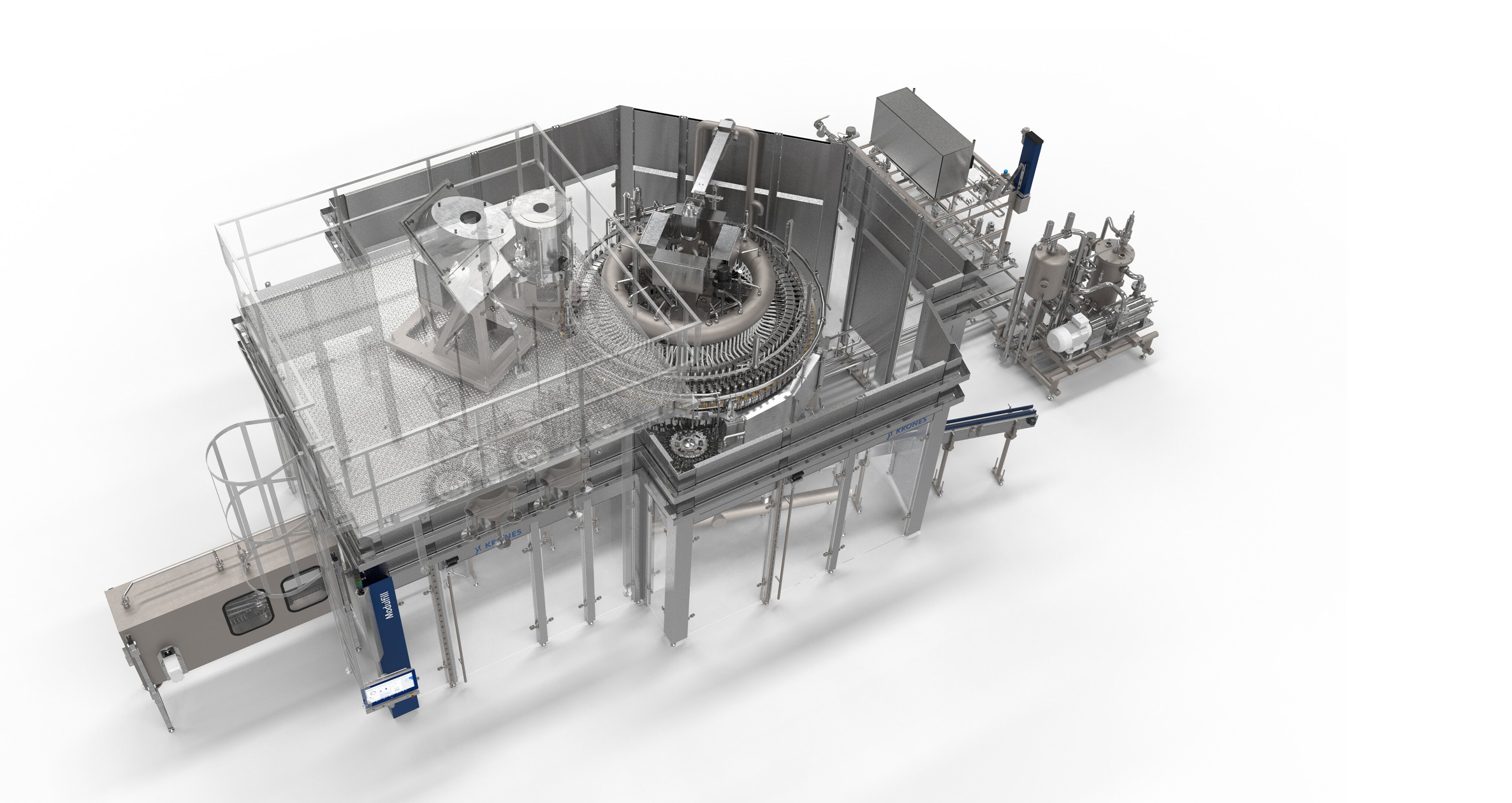

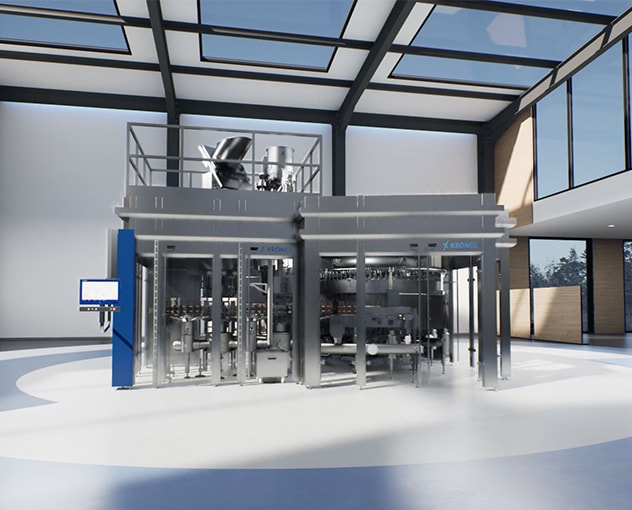

Those who know Krones will also know: We offer just the right filling system for each type of beverage – and are also continually working on making use of new technological equipment and improvements in user friendliness, space saving and, of course, hygiene to improve our products. The Modulfill HES, our expert when it comes to beer filling, recently just undergone such an upgrade.

At a glance

- Numerous revisions and new technological features

- Application: Beer, but also carbonated soft drinks and wine

- Output: Up to 78,000 containers per hour

HES = Height filling system, Electronic fill height measuring, Short tube

The features at a glance

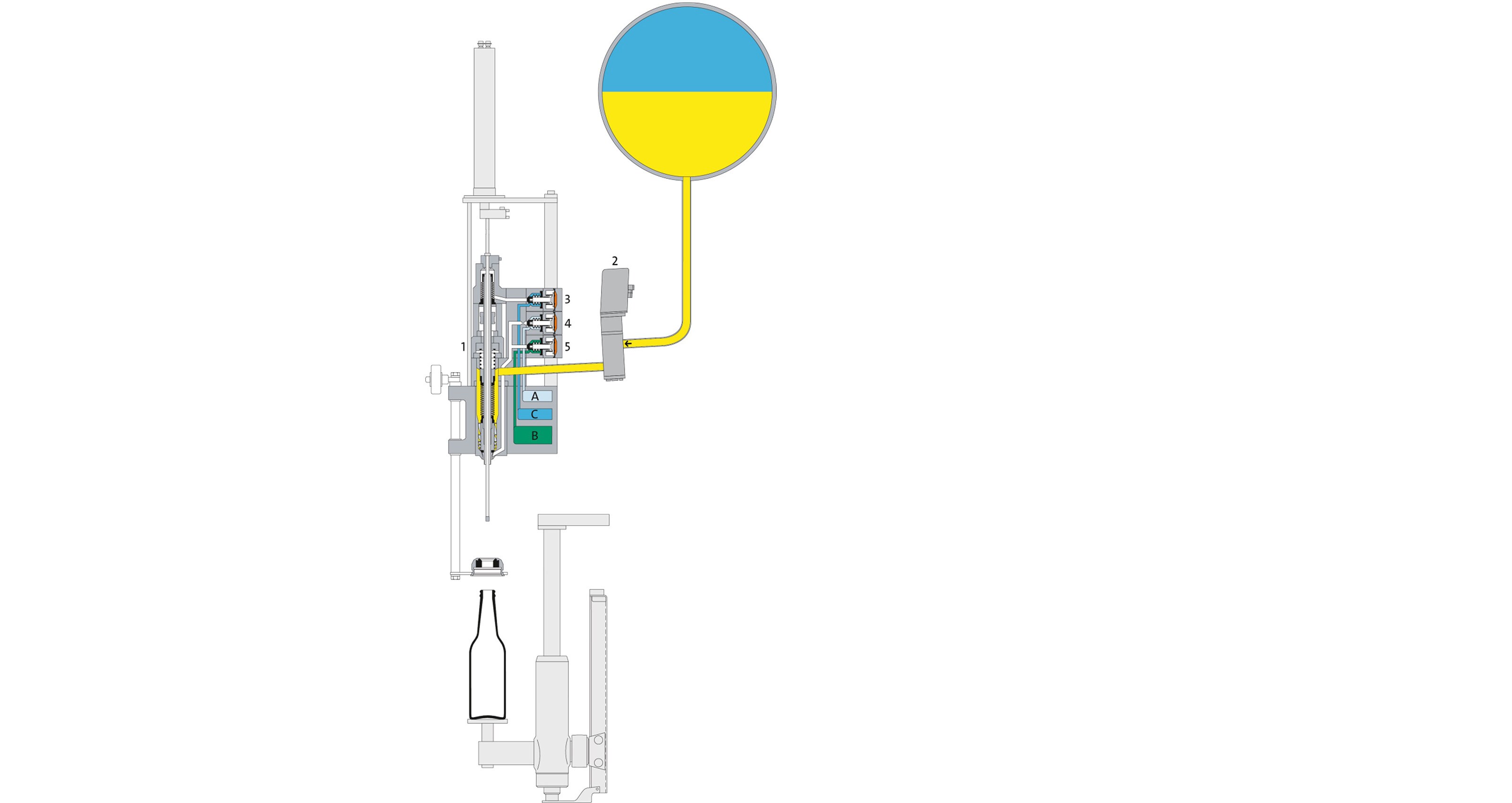

Integration of the latest PFR valve

Highest filling precision with the greatest flexibility

Whereas conventional filling valves only fill at a fast or slow rate, the speed of the PFR valve can be infinitely adjusted –primarily having a positive impact on the filling precision.

Advantages

- Individual control of the filling speed for every type of product. No losses due to the product foaming over

- Decentralised pneumatic components thanks to the PFR, no electronic cabinet

- Compressed-air consumption reduced by up to 30 percent

- Gap-free hygienic centring bell made from one piece

The benefits

Numerous advantages with a view to sustainability

The numerous optimisations in the process and the design details of the Modulfill HES ensure that the filler scores plus points in the economical use of media:

- Thanks to the revised, electronically operated PFR valve, compressed air consumption can be reduced by up to 30 percent.

- The process gas regulating system enables optimal CO2 management.

- The optimised flushing time results in best oxygen values with low media consumption.

- Thanks to innovative components, permanent lubrication can be dispensed with in both the filler and the capper area.

A myriad of hygiene benefits

The Krones development team has tinkered around with scores of regulating screws in order to improve the Modulfill even further when it comes to hygiene. For example, it has discovered new solutions for dripping and oil-lubricated positions, has optimised existing connections and plates and brought order to its cable guidance systems – and thus ensured that the Modulfill can sparkle when it comes to hygiene.

Reduced change-over times

Time is money – and change-over times in particular may be planned line downtimes, but they are very easy to avoid. Thus, the probes on the Modulfill are now automatically adjusted.

Saved energy and raw materials

The PFR valve operates electronically. This saves 30 percent of compressed air when compared to electropneumatic filling. The Modulfill also cuts costs when it comes to consumables. The new lift cylinder means that oil is no longer needed for lubrication. The lubrication-free rollers of the centring bell rod allow for the omission of water lubrication.

Enhanced product quality

The new PFR valve enables optimum adjustment of the filling speed to suit the particular product properties. Products which tend to foam excessively can also be processed. The filling precision can be further improved when combined with the very precise probe adjustment system.

Inspired by the challenge of the future in terms of sustainability and Krones' corporate goals, we have been working on taking our Modulfill HES for beer filling to the next level in terms of flexibility, sustainability and machine output.

Inspired by the challenge of the future in terms of sustainability and Krones' corporate goals, we have been working on taking our Modulfill HES for beer filling to the next level in terms of flexibility, sustainability and machine output.