Volumetric can filler for filling soft drinks

Sparkling technology for carbonated beverages

Volumetric can filler VFS-C

- For both small and large output range

- 28 to 182 filling valves integrated

- Can heights between 80 and 200 millimetres**

- Pneumatic pressing-on and centring

Output

- 18,000 to 135,000 cans/hour*

VFS-C = Volumetric filling, Flow meter, Short tube, Can

* Depending on the current can format

** Other can heights are possible on request

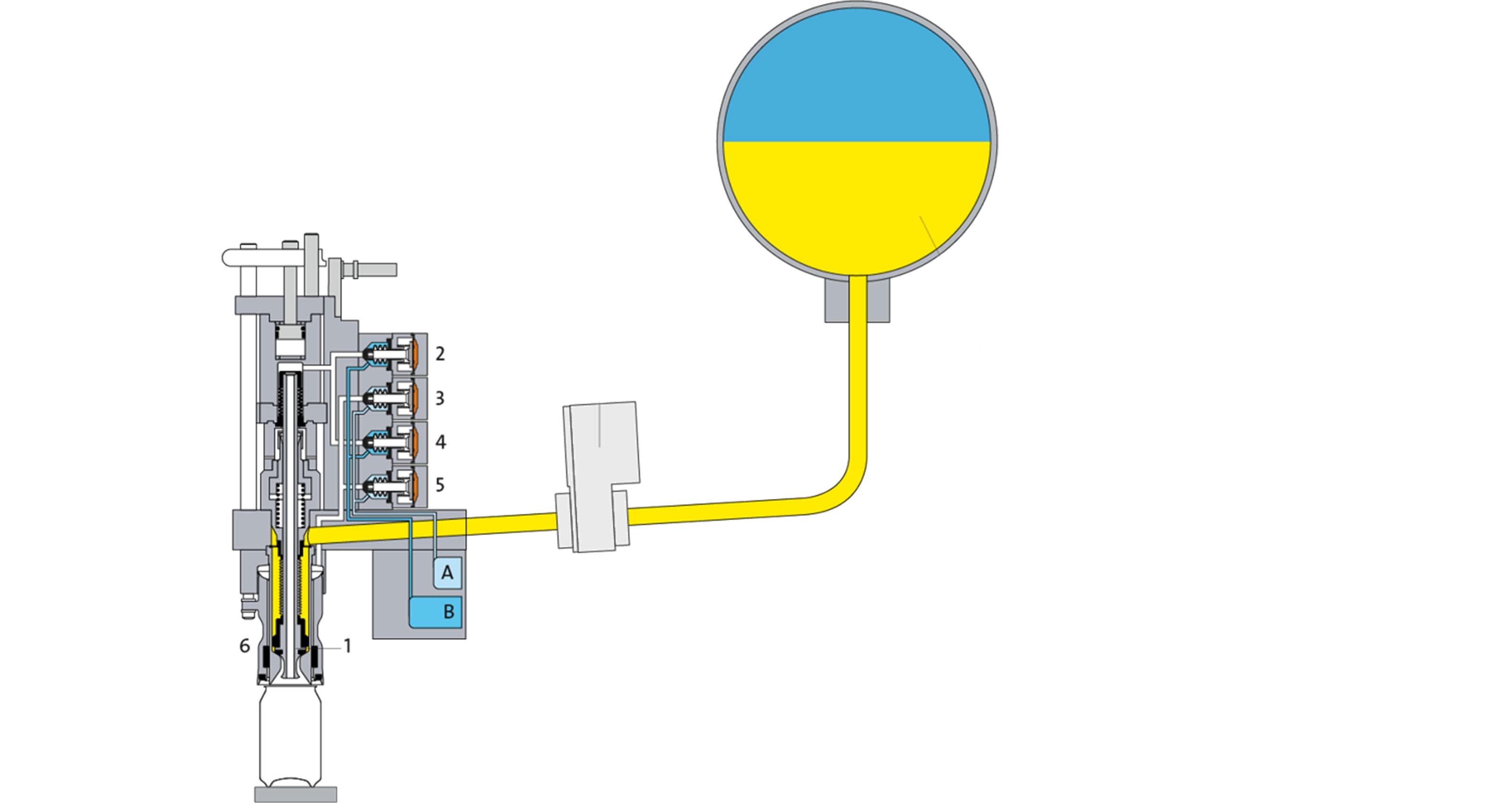

The method of operation of the new filling valve

The can is fed into the filler and positioned underneath the filling valve. The valve is pneumatically lowered onto the can for pressing-on. Thanks to a differential pressure chamber, the cans are also centred and pressed onto the valve with extreme care. The filling process begins immediately after rinsing. An inductive flow meter monitors the fed filling quantity. The valve closes once the specified filling volume has been reached.

Optional

- Cleaning in a closed system using automatically positioned CIP cups

- Design in the clean room housing

Pressurisation channel

Snifting channel

Ring bowl, smaller pitch diameter with central product tank

Inductive flow meter

Centring bell

Snifting valve, can head space

Pressurisation and return gas valve

Snifting valve, flushing

Flushing valve

Product stem

Benefits to you

Best hygiene conditions

- Hygienic filling valve

- Machine concept without a front table but with a consistent use of Krones Monotec starwheel columns

- Grease-free main bearing with automatic oil-circulating lubrication system

Reliable filling procedure

- Separated gas channels for pressurisation and snifting

- Pneumatic pressing-on and centring

- Flushing is performed when pressed on

Operator convenience

- Format-flexible pressing-on unit: several can formats can be handled without handling parts

- Quick-change handling parts

Promoting energy efficiency

- Use of servo drive technology

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events