Creative and economical: a new approach towards can decoration

Cans perfectly presented

Sleeves, or printed films, are applied with a cling-fit to the contours of a container using thermal energy. This makes it possible to achieve all-round decoration whatever the shape of the container. Because cylindrical or contour cans make no difference – if you choose the sleeve as your type of label, there are no limits to the design options: Thanks to a wide range of printing alternatives, every container can be made to stand out.

At a glance

- Brilliant printing quality

- Seamless visual appeal

- Special finishing (high-gloss silver/gold, matt coatings, metallic effect, thermochrome, integrated stickers, UV lacquer, iriodin coatings)

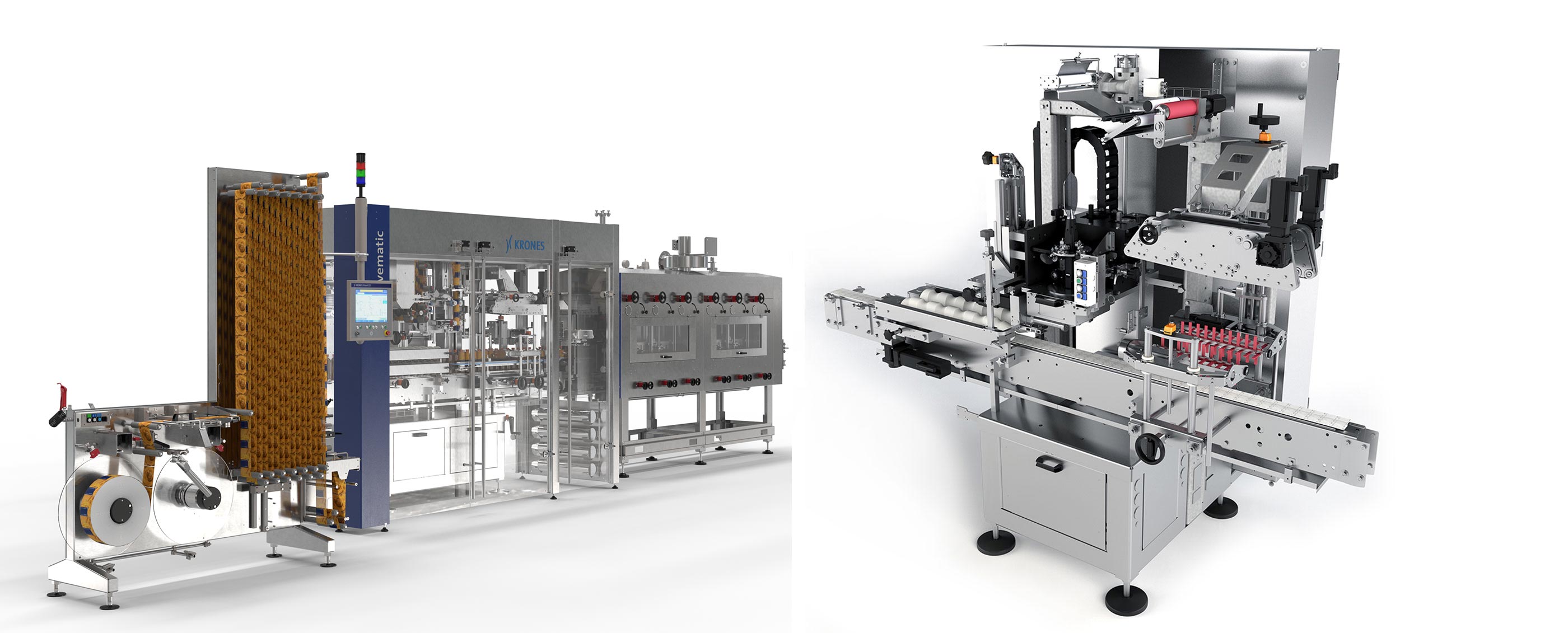

The design

Container discharge

Sleeve brush

Conveyor

Sleeve applicator

Container infeed

Sleeve supply unit

Stand-alone machine guards

Swivelling HMI

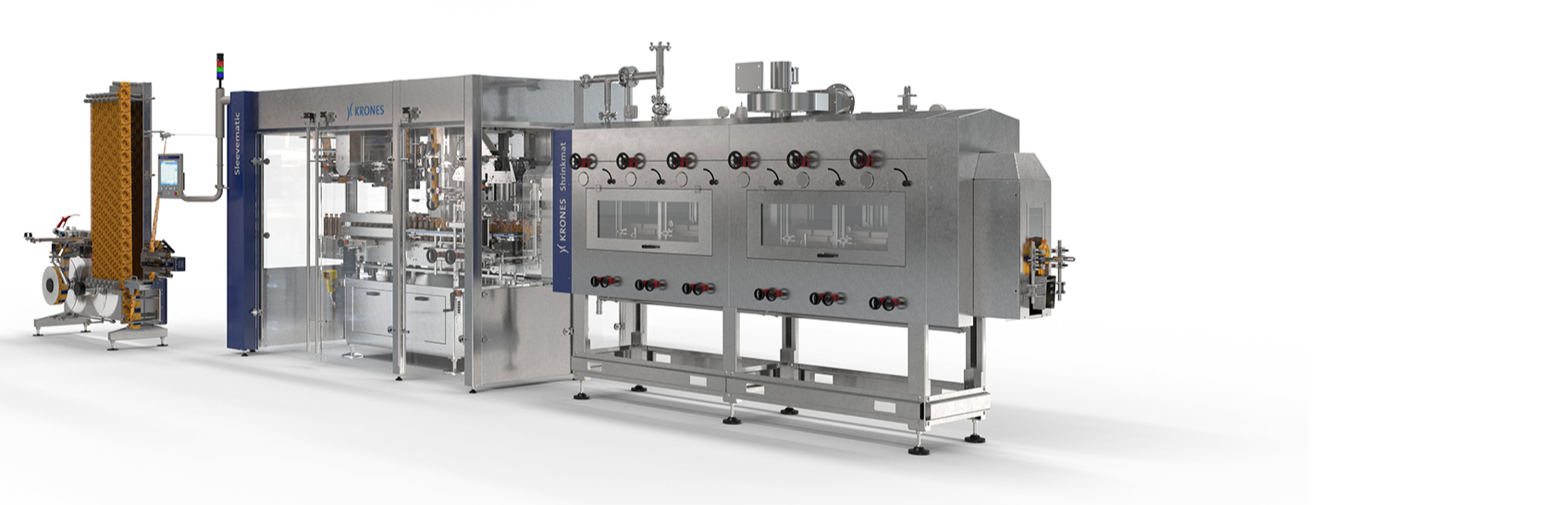

Shrinkmatsteaming tunnel: construction

Container infeed

Temperature gauge

Optional sight glasses

Steam pressure adjustment

Optional exterior steam bar adjustment

Steam extraction

Container discharge

Your benefits

Fast and flexible can decoration

- Fast decoration change-overs by changing the sleeve

- Independence from the can supplier

Reduction in material consumption

- Exact production qualities possible; no can waste

- Reduced logistics, no storage of different printed cans

Marketing advantages

- Time-to-market: fast reaction to changes in the market and new trends

- Maximum flexibility for decoration specification

Production advantages

- Cost-efficient production of small batch sizes

- High system availability thanks to short change-over times

Labelling precision

- Exact cutting length thanks to the servo-controlled cutting unit

Large output range

- A label applicator for up to 40,000 cans/hour

Flexibility

- Wide range of different containers can be processed on one machine

- Independent of the label material

Increased efficiency

- New, completely revised label applicator with mechanical sleeve opening and servo-controlled feed rollers.

- Longer runtime with fewer machine stops thanks to the generous sleeve buffer with manual splicing option

Operation

- Touch-screen with graphical operator interface

- Operation via defined access levels

Security

- Machine guards with swing doors (according to CE regulations)

Production switch

- Motorised labelling station adjustment with quick-change opening mandrel and container guide parts

Maintenance and cleaning

- Optimal accessibility thanks to the compact design

- Little cleaning required (no adhesive)

- Robust, long-life and easy-maintenance design

Hygiene

- Stainless steel (V2A) machine frame

- Container handling parts in open design

Quality

- Machine and labelling stations made by us "Made in Germany"

- Certified to DIN ISO 9001, CE certificate

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events