Project check

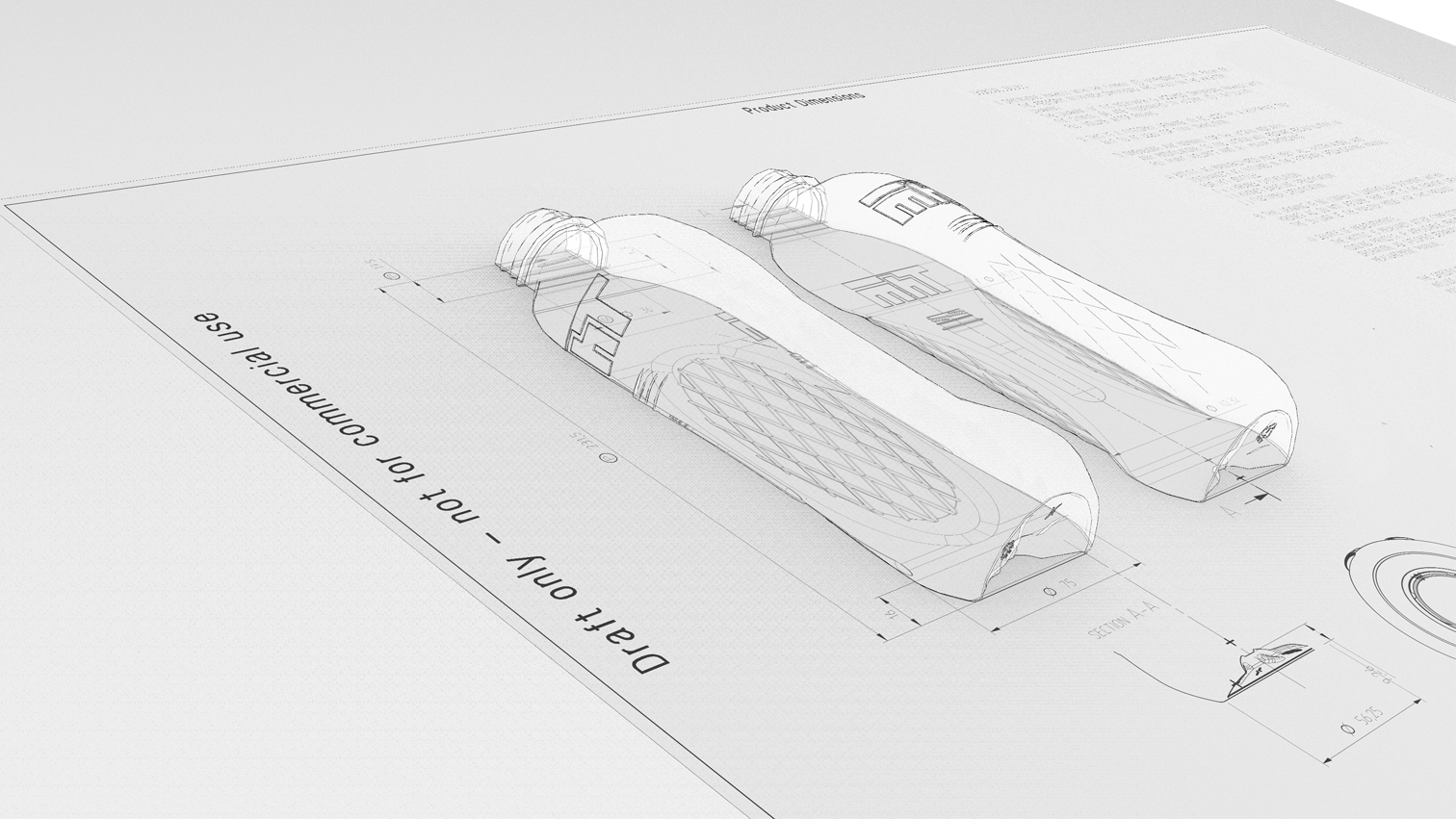

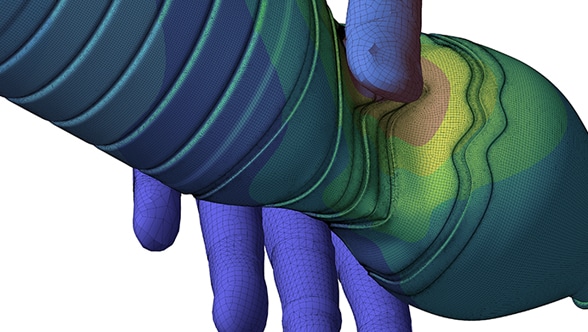

Everything begins with a clear goal: In the project check, we provide you with an overview of our services while simultaneously determining your specific requirements and framework conditions. The result is a definition of goals that we have decided upon together and which the subsequent project contributes to reaching one-hundred percent.