Chiller for Hotfill lines

The Clean Design chiller

What do people playing sports and hot-filled beverages have in common? Both appreciate a welcome cool-down. The latter, at least, can rely on the Krones LinaCool to provide just that: With its sophisticated spraying nozzle system, it cools all products gently down to ambient temperature, in order to avoid distorting their taste or colour.

At a glance

- Spraying nozzle system for quick and defined bottle treatment

- For cans, glass bottles and PET containers

- Stainless steel pumps and conveyors and housing, and the conveyors either of plastic (Marathon Belt) or stainless steel (Ironman Belt), depending on the container type.

- Low infeed height of 1,200 millimetres: easy connection to the line

Facts and figures

Field of applications

Cooling of all products in glass bottles, PET containers and cans

Output

10,000 to 90,000 containers per hour

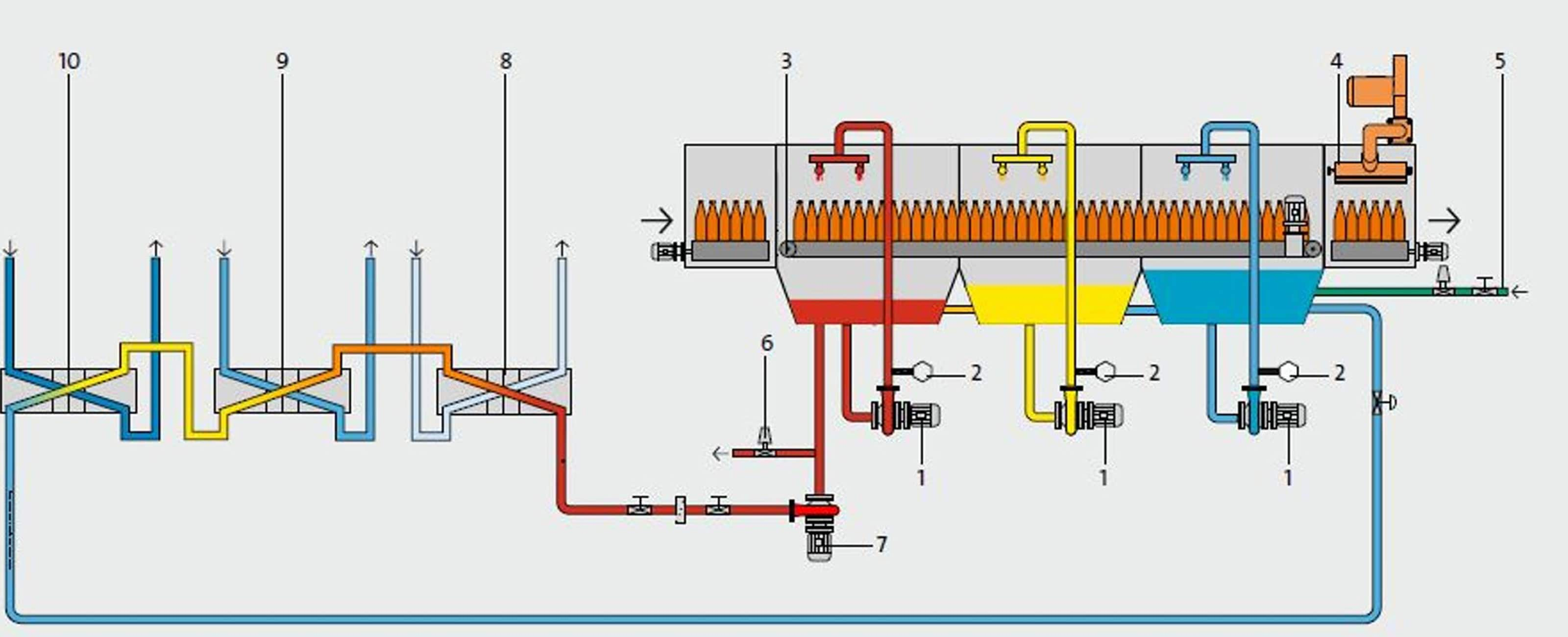

Cooling water pump

Zonenpumpe

Zone pump

Zone pump

Temperature sensor

Temperature sensor

Temperature sensor

Automatic draining

Fresh water pipe

Optional: Blower

Krones conveyor

- Marathon Belt

- Ironman Belt

Optional: Heat exchanger for pre-heating of juice (thermal heat recovery of at least 50 percent)

Optional: Heat exchanger for the cooling tower

Optional: Heat exchanger for refrigeration system

Technical details

Spraying nozzle system

- Snap-in spraying nozzles

- Quick access for maintenance jobs

- Cleaning of spraying nozzle without removal of spraying pipes

Marathon Belt

- Patented roller conveyor of stainless steel and plastic bodies

- Suitable for all container types

- Long service life and low-maintenance due to minimum friction

- Short transfer section for gentle product change-over

- Idle end with welded profiles, no turning shaft

Ironman Belt

- Stainless steel roller conveyor

- Special further development of the well-proven Marathon Belt

- Used in areas where the glass is more likely to break

Machine design

- Multi-part, modular machine concept with infeed and discharge heights

of 1,200 millimetres each - Frequency-controlled drives

- Detachable sieve system for pumps and spraying nozzles protection

- Infeed and discharge with stainless steel doors for optimal protection and accessibility

- Level switch for automatic refilling of fresh water

Hygiene concept

- Clean Design with centralised draining and inclined drip pans

- Optional: Boiling function for optimum cleaning with the minimum number

of staff

Controller

- Operation via touch-screen with display of the operating status

- Automatic filling

- Change-over to another product within minutes

- Type management

- Optional: dynamic control of the cooling capacity with CPC

Heat recovery

System overview

Benefits to you

Optimal control of the cooling capacity

Temperatures and volume flow rate can be dynamically controlled in the LinaCool. The plus points are obvious: a very low consumption of energy with maximum process safety and highest product quality at the same time. When activated, the Cooling Performance Control reduces the required cooling energy by 10 percent at a consistent discharge temperature.

Conveyors with a long service life

In order to transport all containers safely, the LinaCool counts on plastic conveyors (Marathon Belt) or stainless steel conveyors (Ironman Belt). Thanks to their minimal friction, they are resistant to wear and provide a long service life of up to 20 years.

Highest hygiene standard

The Clean Design with inclined drip pans and centralised draining provides ideal hygienic conditions and guarantees that no water remains in the machine.

Modular machine concept and high-quality design

The LinaCool consists of multiple modules which are pre-assembled and tested prior to shipping. This significantly reduces the installation time on site by up to 50 percent.