A new dimension in container distribution

Highly flexible and gentle distribution of containers

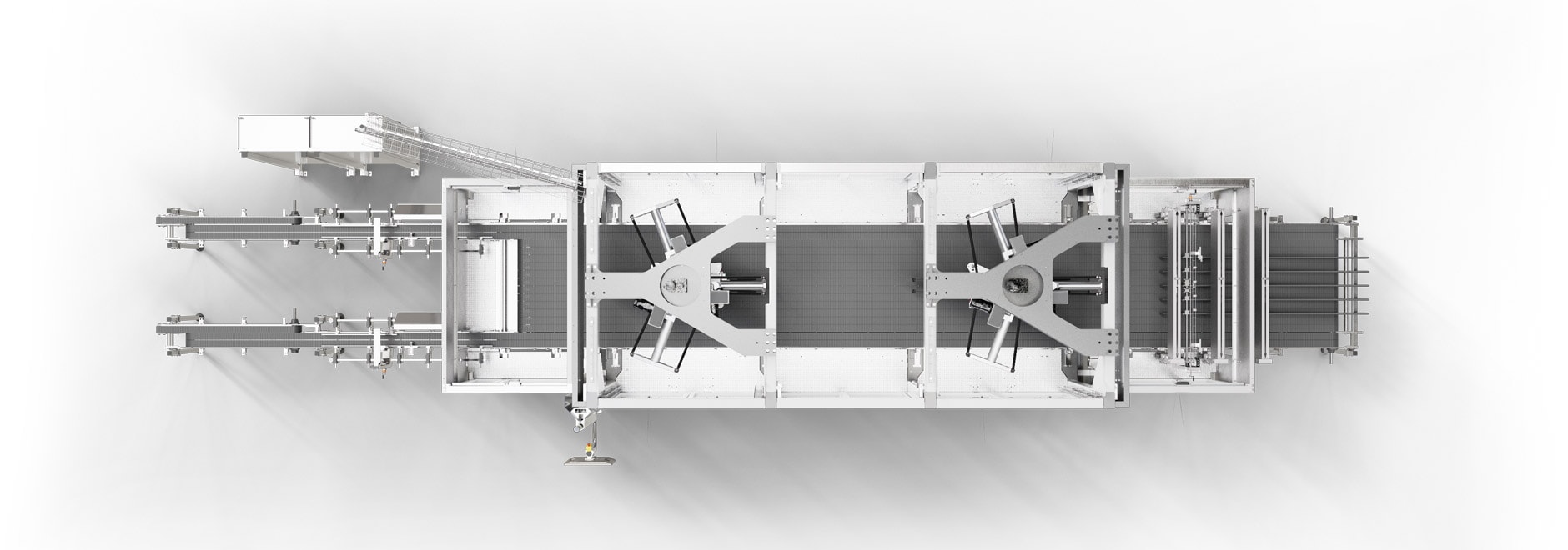

The Robobox SynFlow is a modular system which distributes containers reliably and gently into designated lanes for further handling. The robot employed operates with parallel kinematics. Thanks to its positive-fit precision grippers, the Robobox SynFlow can be used to handle all conventional container types.

At a glance

- Positioned at the Variopac Pro packer feed

- One or two-lane container feed (also with gaps between the containers)

- “1 to n“ for up to 55,000 containers per hour*

- “2 to n“ for up to 105,000 containers per hour*

- Possible number of lanes leading to the Variopac Pro: 3 to 9

- Suitable for all container types (glass, cans, PET)

- For bottle diameters between 40 and 125 millimetres

- Ideal for specially-shaped containers

* Reference container: 0.5 litre PET bottle

Technical characteristics of the gripping arm

A tripod robot with a parallel kinematic structure is used in the Robobox SynFlow. It operates according to the following principle

- All axes operate simultaneously.

- The drives are installed at a fixed position so that they do not need to be moved along with the rest of the system.

Benefits to you

- Use of a second module for higher outputs

- Low-vibration operation

- Increased rigidity and with improved collision resistance thanks to a torque monitoring system

- Low maintenance requirement

Functional characteristics

Any lane can be approached:

- No fixed distribution pattern

- Lane adjustment for each distribution process

Option: speed reduction (1 to n)

- Discharge conveyors with half the speed

- Fewer transfer sections at the discharge

This is why the Robobox SynFlow is enviro-classified

- Environmental compatibility:

- Minimised water and lubricant consumption through the use of dry lubrication (where technically possible) and use of state-of-the-art plastics

- Consistent use of food-safe greases and oils for the lubrication of bearings and gears

- Energy efficiency

- The highly efficient PM drives save up to 50 percent of energy (compared to conventional asynchronous motors)

- Its stand-by mode reduces the power consumed during a standstill

Benefits

Gentle and precise container handling

Positive-fit precision grippers guide the containers gently, reliably and precisely to their intended position. This not only ensures high product quality, but also process reliability to the packer infeed.

Quick change-over

If the container needs to be changed, the grippers automatically adapt to the new format. As the Robobox SynFlow does not require any product-specific components, change-over times can be kept extremely short.

Quick installation and commissioning

Almost all components are pre-assembled in the factory and commissioned in advance. This ensures the conveyor to be ready for operation within a very short time using the "plug and play" principle.

Low energy requirement

Due to the exclusive employment of high-performance PM drives an efficiency rate of 90 percent is achieved. The power consumption is significantly lower than with asynchronous motors.

Flexibility and efficiency

Depending on requirements, the feed can include one or two lanes.

Low space requirements

The Robobox SynFlow only requires a small amount of space for installation. This allows a compact layout to be created in front of the packer.