The Covid-19 pandemic had a massive impact on the global economy in 2020. Krones’ business was also hit. We will continue to feel the impacts of the corona crisis beyond 2020, and we still face challenges in the short term. Krones nevertheless looks with confidence to the future.

The company operates in long-term growth markets. We also have other strengths that we have built up over the past years and decades.

Krones positioned itself early to benefit from the megatrends of sustainability and digitalisation. We have unique line expertise and a strong global footprint. Despite heavy investment in the future, the company’s financial and capital structure is very solid.

Krones will focus on its strengths for continued success and profitable growth in the medium and long term.

Krones’ strengths

Consumption of packaged beverages was slightly down in 2020 due to corona. But in the medium and long term, demand is rising. Eating and drinking are basic needs. And the population is steadily growing. In addition, two further megatrends mean that consumers are increasingly frequently opting for packaged beverages and foods. Firstly, more people in emerging and developing countries are joining the middle classes. Consumption increases as incomes rise. Secondly, more and more people are moving from rural areas to cities, especially in Africa and Asia. This urbanisation drives demand for packaged foods and beverages as people align their lifestyles and consumption patterns to city living.

Krones provides innovative and also regionally adapted machines and lines enabling food and beverage producers to fill and package their products efficiently and safely. As the leading full-service supplier of bottling and packaging equipment, we can exploit the opportunities of growth markets.

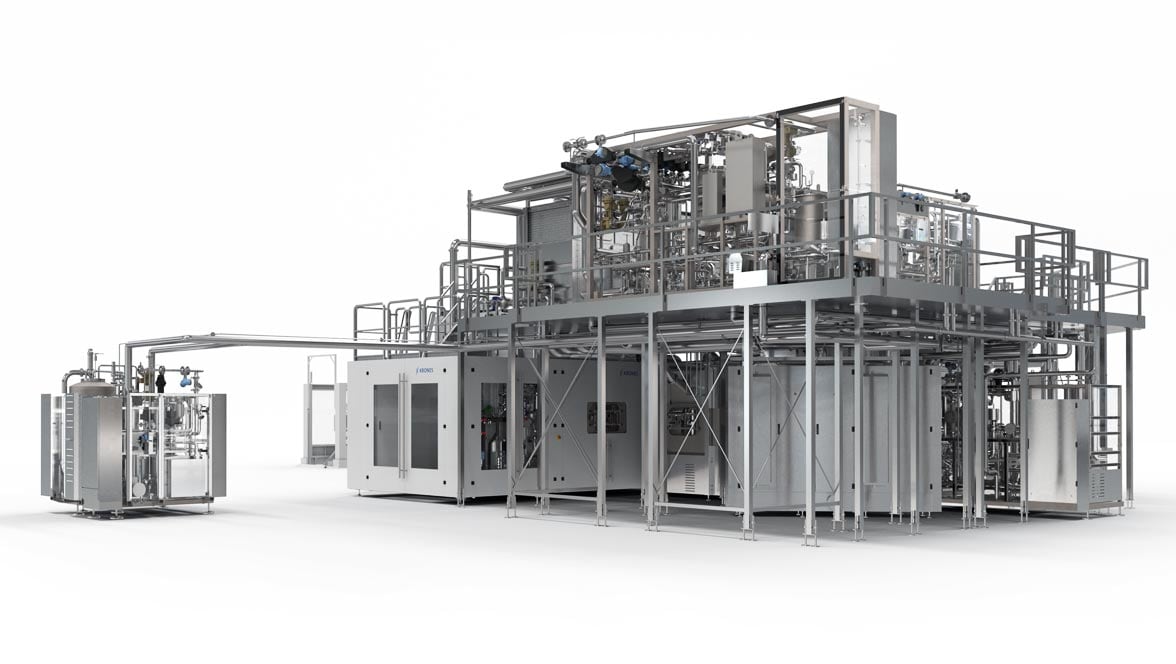

Aseptic line for sensitive beverages

Tea is very popular in Asia. It is a drink that is traditionally enjoyed at home. But urbanisation means that tea is also increasingly frequently consumed on the go – and consequently in bottled form. This drives demand for high-performance and safe filling and packaging technology.

At the end of 2019, for example, Nui Tien Pure Water, a subsidiary of the Vietnamese TH true Milk group of companies that previously focused on milk production, invested in an aseptic line made by Krones. The line for aseptic filling of sensitive products is suitable for tea, but also for juices with particles, dairy milk and rice milk. It has a capacity of 36,000 PET containers per hour. In addition to the filling and packaging equipment, Krones also supplied a syrup room with integrated tea extraction.

A filling and packaging line is made up of many individual machines and systems. These include inspectors, PET bottle blowers, fillers, labellers, packers and palletisers. Each of these is a highly efficient unit on its own. Combining them into an efficient and reliable production line requires them to be perfectly coordinated. Thanks to many years of experience and profound knowledge of the entire production process in a filling and packaging line, Krones has full mastery over interoperation between the individual components.

The individual machines are coordinated so that the entire production process runs perfectly smoothly and the filling and packaging line delivers maximum performance. Krones is also able to use its line expertise in digitalisation. We know what communication is needed between individual line components and what parameters to monitor and control. Krones’ line expertise provides the foundation for exploiting the opportunities of digitalisation.

Canning line: ultra-high performance

Hungarian brewery Borsodi selected Krones to provide a complete beer canning line. Krones supplied all machines and components for the new line, from the empty can depalletiser and inspector to the flash pasteuriser (VarioFlash B), filler (Modulfill VFS-C) and full can palletiser (VarioPac).

The line meets Borsodi’s demanding requirements with over 90% efficiency and a throughput of 50,000 cans per hour. As well as being highly efficient, the line stands out with short changeover times, excellent product safety and energy economy. A further upside was rapid installation. Just ten months went by from order placement to the moment the first retail-ready beer can came off

the production line.

The corona crisis significantly accelerated the trend towards digitalisation in the filling and packaging industry. Krones has already been investing heavily in digitalisation for years. This incurred initial losses, but the investment is now paying off. Krones already has considerable digital expertise and provides customers with digital solutions such as remote service.

Transforming our successful products and services into the digital world is extremely important for the company’s future success. Over 300 software engineers and IT specialists work on digital innovations at Krones. The focus in all of these innovations is on added value for our customers.

Our filling and packaging lines are becoming smarter and provide customers with valuable added benefits. For customers, alongside lower production and labour costs, it is important that they can produce flexibly, that all production steps are transparent and that problems are quickly resolved. To this end, Krones aims to provide customers with digital tools and services on a single platform that keeps track of the entire line. We are well positioned to achieve this ambitious goal.

Highly digitalised line

Altmühltaler Mineralbrunnen is one of Germany’s biggest beverage producers. Krones has now delivered its seventh PET line at the Breuna production facility.

The new line, like all the other plants, is highly digitalized and to this end features various solutions from the SitePilot Suite: the Line Management job order control system, the Line Diagnostics plant analysis system and the Asset Management maintenance and repair tool. The SitePilot Planning production planning and control system creates a production plan for each line and generates a job order list from it. This full production plan then goes into the Line Management System. When the operator starts production, the system then already knows exactly what materials are needed and provisions the raw materials, consumables and supplies fully automatically on an electric monorail. Conversely, it is also possible to trace back exactly what product was produced and filled with what inputs and when. This practically rules out production errors.

Operating sustainably and delivering on our corporate social responsibility have always been very important to Krones. Sustainability has also long been a priority for Krones customers. We introduced the enviro sustainability program as long ago as 2008. enviro is an externally audited management system that shines the spotlight on the eco-efficiency of the Krones product portfolio.

The enviro program systematically improves the energy efficiency of Krones products and has already delivered substantial savings for customers. enviro has also enabled Krones to gain a competitive edge. We are able to provide machinery and equipment that help customers achieve their ambitious sustainability goals. For this purpose, they need both high-performance and resource-efficient production equipment. Krones has set itself the ambitious target of reducing the carbon footprint of produced machines and lines in the upstream and downstream value chain (Scope 3 emissions) at the customer by 25% from 2019 to 2030.

innocent selects Krones based on sustainability credentials

Smoothie and juice producer innocent drinks is building the first bottling plant of its own in Rotterdam, called ‘the blender’. Sustainability is a top priority here. For example: the factory will be completely carbon neutral and water use is to be cut to a minimum. Based on its strong sustainability credentials, Krones secured the contract for four complete PET filling lines. Each of the four identical PET lines fills up to 32,000 bottles per hour.

The Contipure AseptBloc DA blow moulder/filler block consists of a Contiform 3 Pro stretch blow moulder and a Modulfill Asept aseptic filler. innocent made a particularly sustainable choice with the Contipure D preform sterilisation module. The module has lower consumption of hydrogen peroxide, steam and energy.

Even after the high level of investment in recent years, Krones continues to have strong finances. The equity ratio was 39.4% at the end of 2020. Krones’ liquidity position is also comfortable. Even in the difficult 2020 financial year, the company maintained liquidity reserves of around €1 billion for almost the entire year. Last year, the company generated a free cash flow of €221.3 million. At the end of 2020, Krones had a net cash position (cash and cash equivalents less bank debt) of some €185 million.

Krones’ high financial and capital strength gives the company sufficient financial scope to master short-term challenges, invest in key technologies and finance future growth.

Solid financial and capital structure enables high levels of investment

Krones has invested heavily in expanding its international service and production locations and in digitalisation in recent years. As the company was mostly able to finance this investment out of its own resources, the Group’s equity ratio remains a very solid 39.4%.

Krones also managed well in the 2020 pandemic year and generated a large free cash flow. The company’s liquidity cushion has grown to €217 million, creating sufficient scope for action.

International food and beverage companies produce worldwide. Customer proximity is the key to responding quickly to customers’ needs. This is a decisive competitive advantage, especially in the service business. Krones operates service centres and branches at over 100 global locations. Spare parts and qualified staff who speak the customer’s language are quickly on site anywhere in the world.

Krones also has global reach in production and procurement. Among other places, we manufacture products in China for local markets. Our international facilities also produce spare parts and in some cases supply products to our German manufacturing plants. Under the direction of special regional teams, Krones sources an ever-increasing volume of materials on international procurement markets.

All of this requires qualified international personnel. Krones has substantially expanded its foreign workforce in recent years and will continue to do so for the medium term. At the end of 2020, Krones employed a total of 6,372 people internationally, 4,055 of them in emerging markets.

Krones always close to the customer

Krones has been expanding its global network for many years in order to strengthen the service side and use the benefits of international procurement and production locations. The new plant in Debrecen, Hungary, which is set to go into full operation in mid-2021, enables Krones to strengthen its international competitiveness and reduce production costs from 2022 by some €20 million a year.

In the fast-growing Asia and Africa regions, Krones not only operates a production plant in Taicang, China, but also has well-established service centres close to its customers. Krones scores well with customers thanks to its highly qualified service force in each region. This is also reflected in heavy investment in international training centres, such as in Kenya and China.