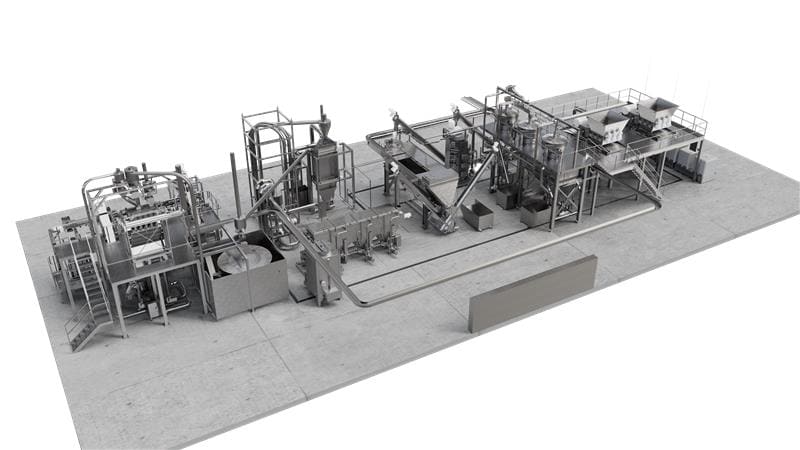

The new MetaPure Compact – Efficient washing technology for small spaces

- The new MetaPure Compact offers maximum washing quality on a markedly reduced footprint

- Modular options enable customisation of this compact solution and reduce project lead times as well as the time and effort involved in installation

- With MetaPure Compact and MetaPure Performance, Krones Recycling now covers the key needs of the industry

The plastics recycling industry is under rising pressure to operate more efficiently and sustainably and on a smaller footprint. While demands on the quality of recycled material are increasing, the amount of space available in many plants is limited.

In response to these needs, Krones Recycling GmbH has developed a new configuration of its washing module, the MetaPure Compact, which delivers outstanding process quality while taking up very little floorspace. With that, the solution addresses one of the industry’s key requirements: maximum efficiency on a minimised footprint.

Small but mighty

The new MetaPure Compact was conceived specifically for production environments where space is limited. It significantly reduces the floor area needed while delivering the same washing quality as larger lines. The configuration has been designed to ensure especially careful processing, which largely avoids generating fine particles. Besides its gentle washing profile, the MetaPure Compact scores points with energy-efficient operation and a resource-saving media management system. Manufactured of high-quality stainless steel, it is suitable for processing PET bottles and food trays as well as HDPE, PP and PS. Its input capacity ranges from around 1.5 to 6 tons per hour.

Standardisation with flexible options

The standard version of this compact configuration covers the essential requirements for a washing module and can be installed and commissioned in less time. A catalogue of modular options makes it possible to add specific needs-based functions that range from process-side modifications to monitoring and service packages. The compact design directly impacts total cost of ownership by reducing the amount of space required as well as energy and water consumption, shortening supply lines and cutting the amount of time and effort involved in installation and maintenance. All of these factors help to minimise investment and operating costs.

Tried-and-tested technology, restructured

Right alongside the compact version, a second product line will remain in our portfolio to continue to meet the equally important needs of many operators. The MetaPure Performance, which is based on the original MetaPure W, was developed to handle complex scenarios requiring a particularly high level of line availability and a robust response to challenging circumstances – for instance, where several different products are to be processed on one and the same line. In order to even better meet these needs in the future, targeted optimisation measures have been undertaken. As a result, the module now operates even more efficiently while delivering the same excellent performance.

A well-conceived portfolio, in every respect

With its MetaPure product line, Krones Recycling offers a clearly structured new portfolio of scalable, resource-efficient and practical-to-integrate washing technology for a variety of requirements. MetaPure Compact addresses increasing space and cost pressures without compromising on quality. MetaPure Performance is an optimised version of the tried-and-tested original, ideally suited for those situations where availability and robustness are the primary considerations. For plant operators, that means greater flexibility in planning, better adaptability to individual material properties and clear prospects for producing high quality recyclates in stable, cost-efficient processes – even where space is at a premium and every square meter counts.

About Krones

The technology company Krones headquartered in Neutraubling, Germany, is a global leader in developing and manufacturing state-of-the-art machines and complete lines for the fields of process, filling and packaging technology. Its portfolio is perfectly complemented by additional products and services provided by the Krones subsidiaries, such as solutions for anything to do with digital transformation, intralogistics and plastics recycling. Krones employs more than 20,000 people worldwide. Consolidated sales in 2024 totalled 5.3 billion euros. The Krones Group includes not only Krones AG (listed on the stock exchange), but also more than 100 subsidiaries and further production, sales and service companies worldwide.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl