Setting new standards in high-pressure homogenization

- High throughput for industrial use: The HLI 132 processes up to 26,500 litres per hour, making it ideal for large-scale applications in the food, chemical and pharmaceutical industries.

- Energy-efficient and sustainable: With integrated valve control, internal lubrication and no need for external cooling systems, it significantly reduces water and energy consumption.

- Hygienic and compact design: Compliant with EHEDG and 3-A standards, the unit offers aseptic options, quiet operation (<85 dB), and easy integration into existing production lines.

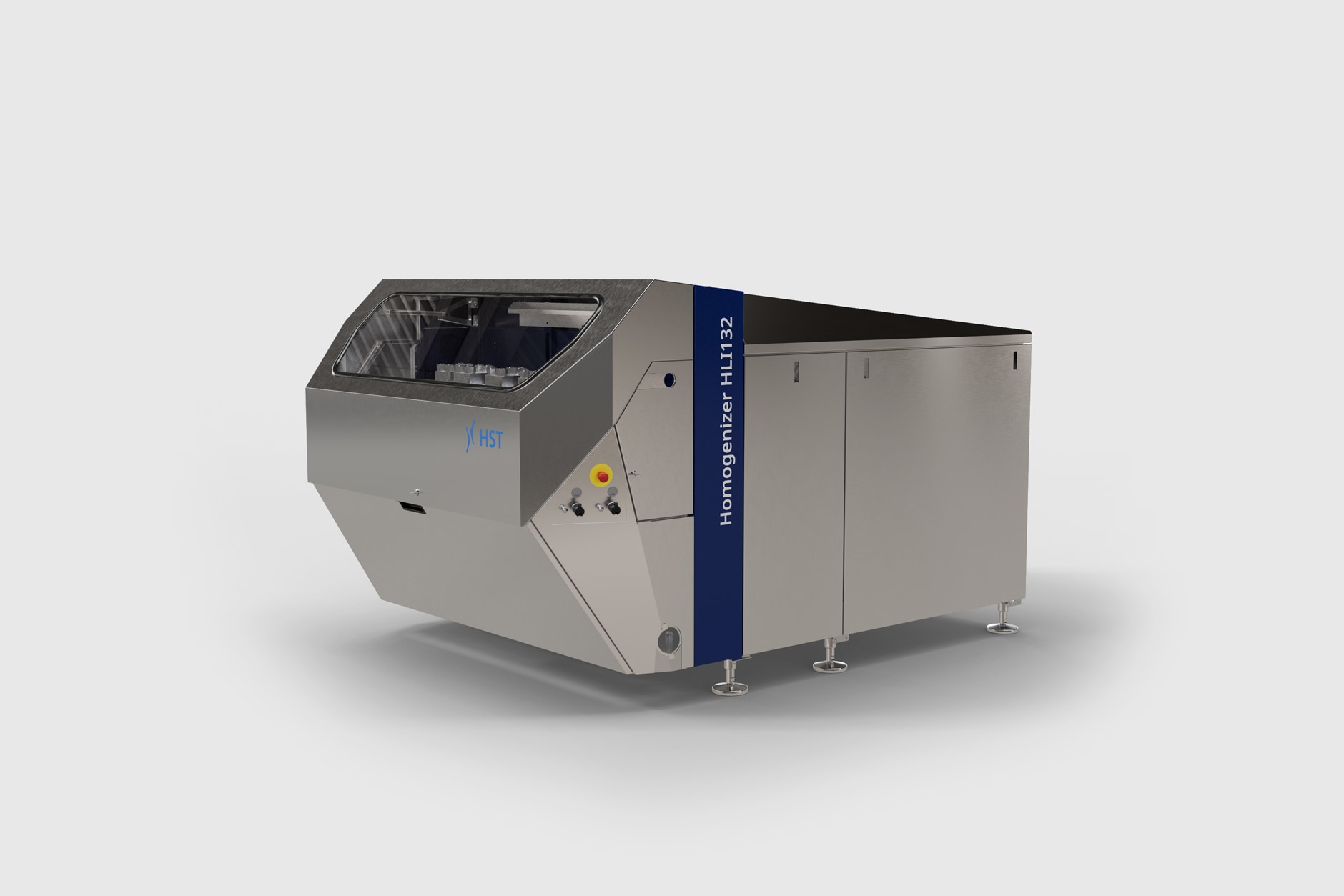

Whether it’s milk, juices or pharmaceutical products – A homogenizer is needed wherever liquids with a particularly fine texture have to be processed in order to create shelf-stable products. HST is expanding its field-proven HLI series to include a new model, the HLI 132, which performs this vital job with impressive efficiency and sustainability.

With a flow rate of up to 26,500 litres per hour (depending on the operating pressure), the HLI 132 is the ideal choice for industrial applications where large volumes have to be processed efficiently.

Focus on energy efficiency and sustainability

The process of homogenization uses high pressure to force the product through a special valve. The homogenizing valve integrated in the HLI 132 permits precise pneumatic adjustment, thus enabling it to be optimally matched to different product characteristics.

In the homogenizing zone, particles or fat droplets are substantially reduced in size. Thanks to a compact drive (55 – 132 kW) and internal lubrication, the HLI 132 does not need any additional cooling water or any external devices. That results in lower operating costs and an economical use of resources, which enables companies to save large amounts of energy and water each year.

Hygienic design and high-precision valve technology

The HLI 132 meets ultra-stringent hygiene standards: CIP for good cleanability, avoidance of dead spaces, and surface quality in conformity with EHEDG (European Hygienic Engineering & Design Group) and 3-A standards (a comprehensive set of voluntary guidelines for the hygienic design and fabrication of equipment used in the food, dairy, beverage, and pharmaceutical industries). An aseptic variant with a sterile-water unit is also available as an optional extra. That ensures maximum process safety and reliability, especially for sensitive products like baby food or pharmaceuticals.

Compact design, low noise, top performance

The HLI 132 scores highly not only with its excellent performance but also with a soundproofing enclosure (<80 dB) and a compact stainless steel design, which facilitates its integration into existing production lines as well as maintenance work. That means HST is able to offer a solution that successfully aligns best possible product quality, efficiency and sustainability, thus providing manufacturers with a genuine competitive advantage.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl