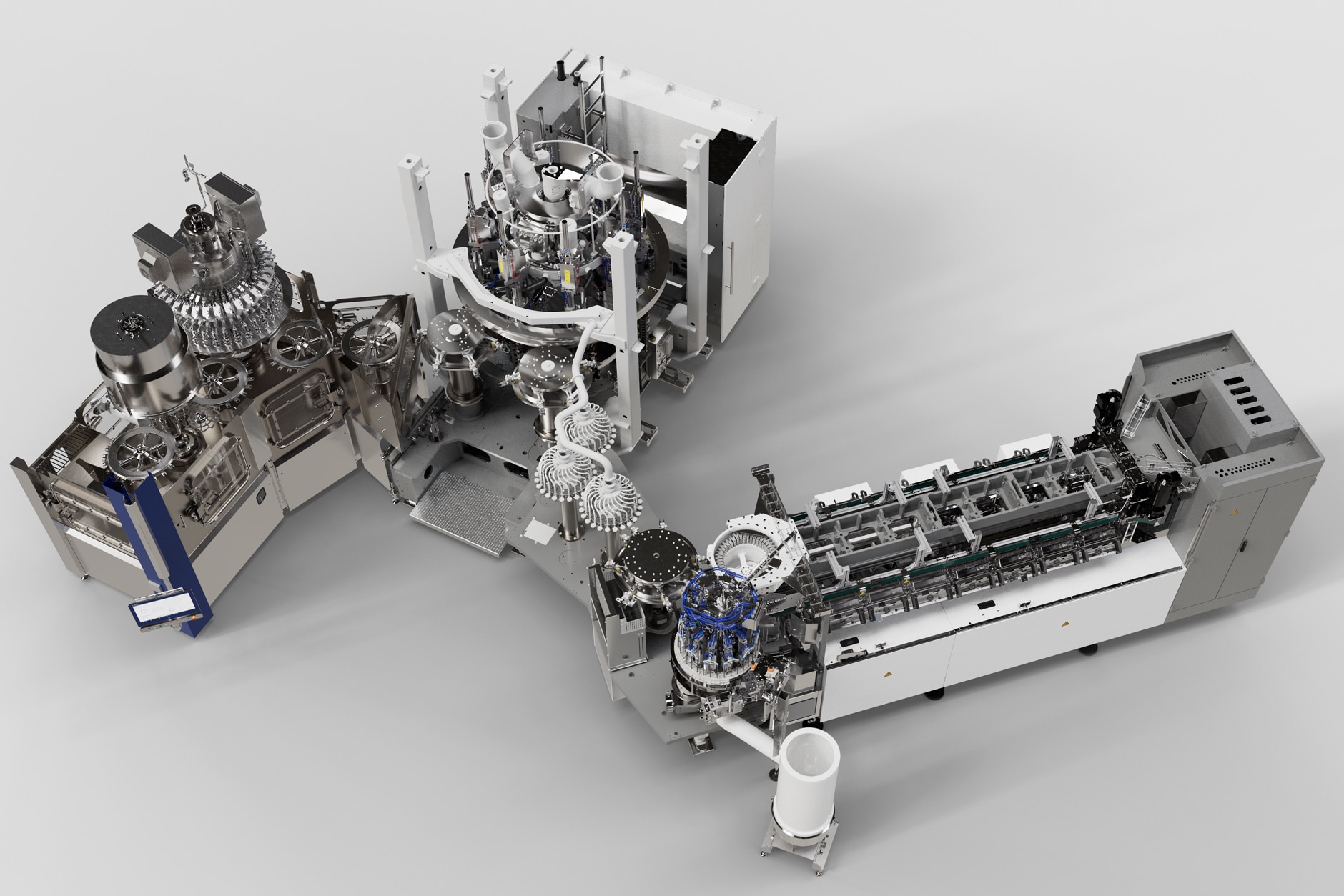

Big technology on a small footprint

- Compact design: Integrates preform sterilisation, stretch blow moulding and aseptic filling in just 100 m² – ideal for small batches and limited production space.

- Versatile performance: Suitable for all still beverages, with outputs from 8,000 to 27,500 bottles per hour and sustainable sterilisation using gaseous H₂O₂.

- Smart engineering: Short transfer paths, tankless CIP, automatic format changes and integrated inspection systems ensure safe and efficient operation.

A growing diversity of products, ever-more-stringent hygiene standards and limited space in production halls combine to present beverage manufacturers with considerable challenges. What they need, then, are solutions that marry the highest levels of product safety with flexibility and efficiency – on a minimised footprint. Now, Krones is bringing to market a compact version of the Contipure AseptBloc – a space-saving variation on its field-proven aseptics technology.

Like the bigger aseptic block solutions, this compact one brings together three key modules in a single, integrated system: preform sterilisation, an aseptic stretch blow-moulder and an aseptic filler with a capper. This block-synchronized unit only requires around 100 square metres of floor space, which makes it the perfect choice for tight quarters in the production environment, for beverage manufacturers producing smaller batches and for new market entrants who want to get into aseptic filling with innovative products.

Exceptional flexibility for a diverse array of products

The system is suited for filling all still beverages, regardless of whether they have high or low acid content. It supports both refrigerated and unrefrigerated distribution and, depending on the container size and product involved, can handle between 8,000 and 27,500 bottles per hour. Just one sterilisation medium is used for the packaging materials: gaseous hydrogen peroxide (H₂O₂), which ensures reliable and sustainable sterilisation.

The Contipure AseptBloc Compact also features impressive engineering, with many clever details: In all, three transfer starwheels between the blowing wheel and the filler make for an extremely short and smooth transfer from one module to the next, while the integrated exhaust air system, which is incorporated in the machine housing, eliminates the need for external pipes. This revamped isolator concept allows for optimal positioning of peripherals such as the media supply system and valve manifold. The integrated tankless CIP module makes it possible to keep both supply lines and cleaning times short. It’s also independent of existing centralised CIP systems. Immediately following the CIP procedure, the product channels are effectively and efficiently sterilised using steam. The entire process takes less than 180 minutes for mildly acidic production and can be shortened further depending on the products involved.

When it comes to reliability, this compact model shares the appealing characteristics of its bigger siblings, giving bottlers the benefit of integrated inspection solutions for preforms, caps and filled bottles. Inside the isolator itself, solutions like skip-and-run functionality on the blowing wheel and the servo-driven capper from Krones support efficient, reliable production. The automatic discharge enables change-overs with no manual interventions in this area. That means the isolator doors remain closed and the operator can concentrate on other aspects of a change-over elsewhere in the line.

Of course, the NitroAdd Asept nitrogen injector can also be integrated for this output range, to dose precisely the right amount of nitrogen to each bottle in turn and thus establish the necessary level of internal pressure for further handling all the way to the consumer.

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl