Krones’ line concept of the future is the first of its kind in the industry

- The new Ingeniq line concept is reliable, sustainable and cost-effective

- Krones is actively assuming responsibility for output, efficiency and life cycle costs

- The configuration for PET lines for non-carbonated water (rated at 100,000 bph) is only the beginning

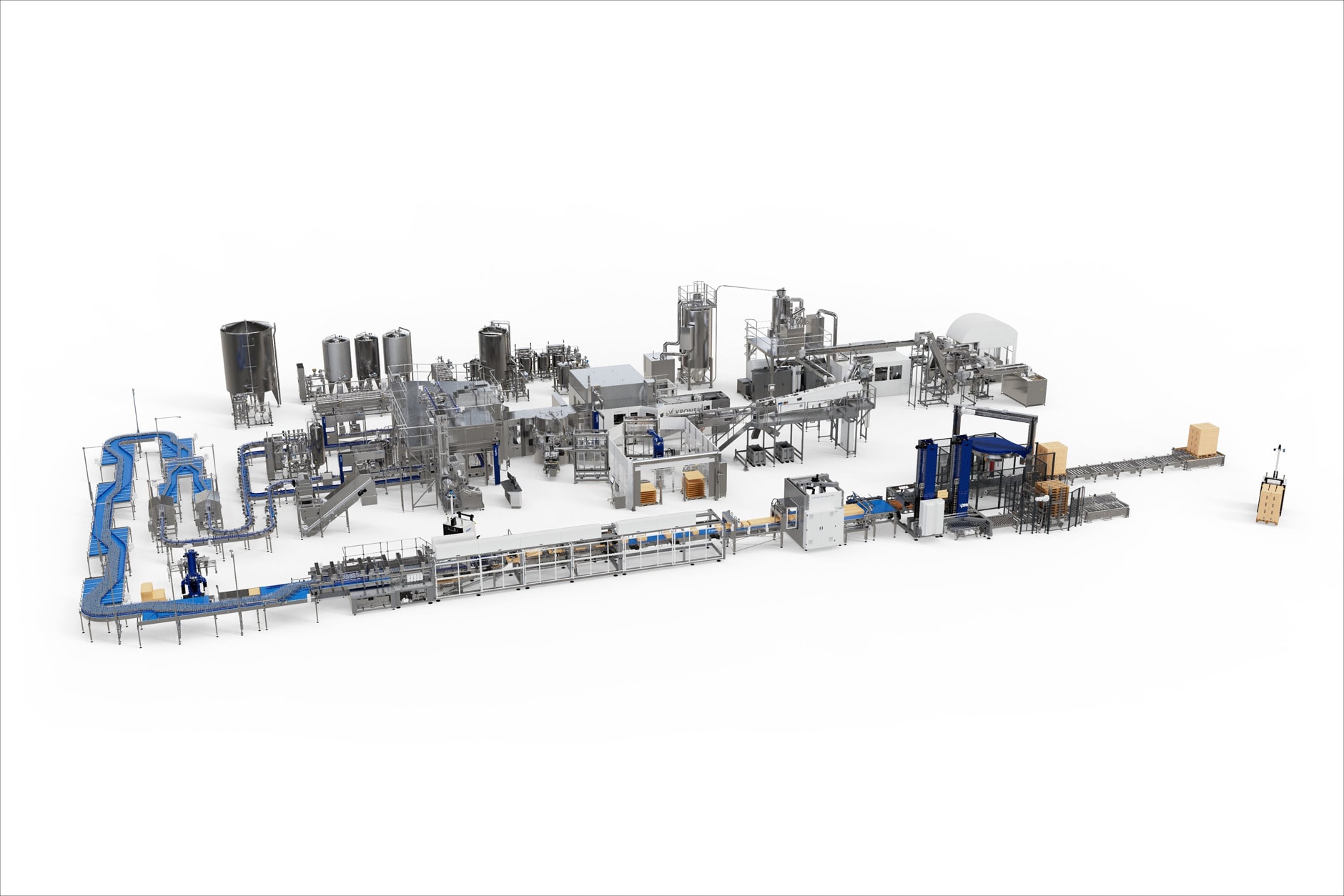

At this year’s drinktec trade fair, Krones is presenting for the first time a data-based, fully automated line system for filling non-carbonated water into PET containers. It’s the line of the future, and we call it Ingeniq*. It was designed as the answer to the most frequent questions (or rather requests) we’ve got from customers recently. And it translates what Krones presented as a vision at drinktec 2022 into shopfloor reality: a line that couples low total cost of ownership with consistently high efficiency.

The system consists of modular and standardised components that leverage robotics and artificial intelligence in a well-thought-out design that reduces the overall complexity of the line layout. “At Krones, we know that our success depends on our customers’ success. That is why we have taken this line concept a step further, forging an alliance with the customer and actively assuming joint responsibility for the entire life cycle – that is something that’s never been done before,” explains Markus Tischer, Member of the Executive Board of Krones AG responsible for International Operations and Services.

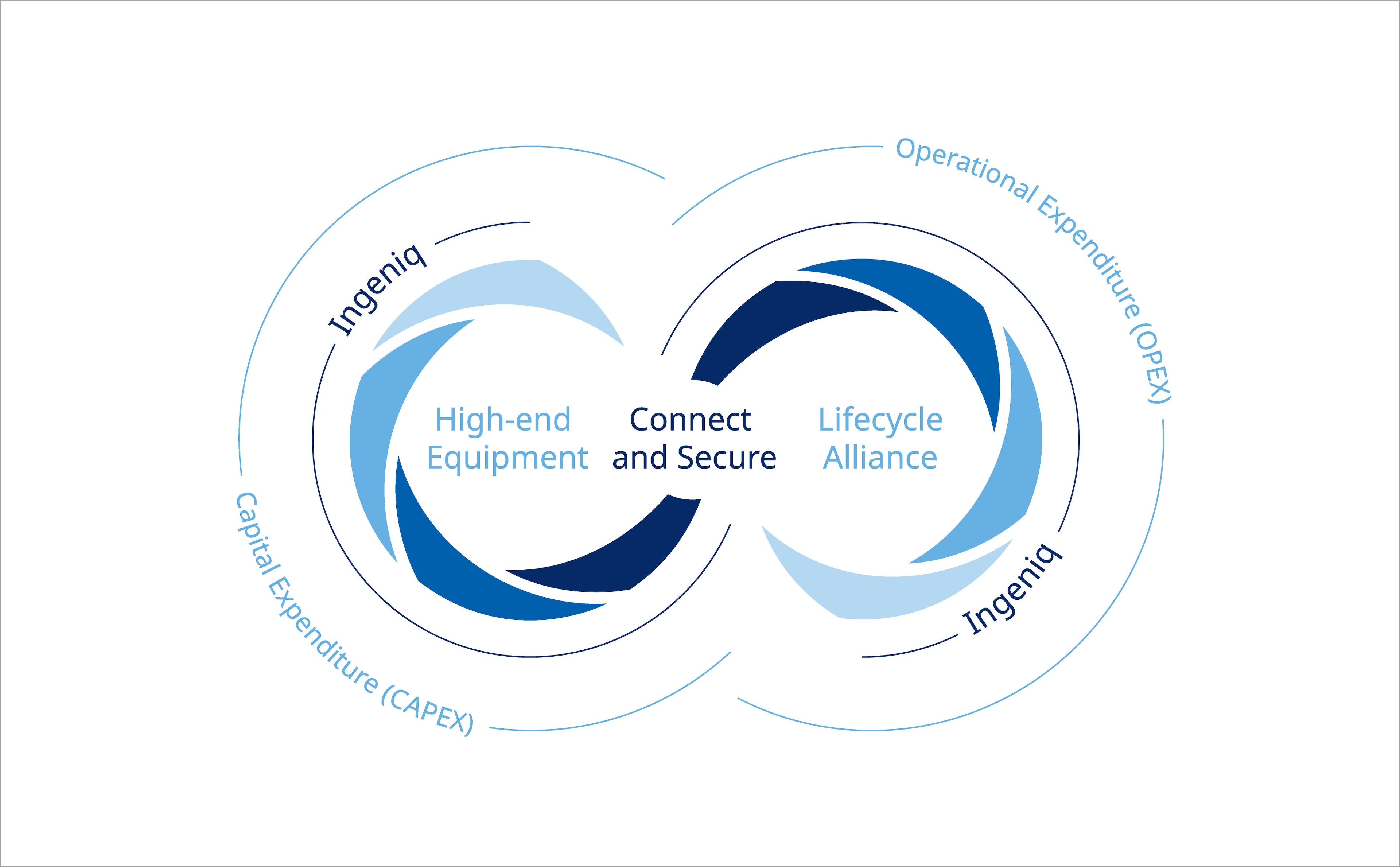

Ingeniq is more than a line. It’s a comprehensive concept made up of the following three components:

- The line itself – technologically cutting-edge, modular and ready for the future.

- Digital access through Krones Connect and Secure – the line is visible digitally and can be supported remotely.

- And, finally, our alliance with the customer, which we call Lifecycle Alliance – Krones assumes responsibility for output and life cycle costs in a modularised service agreement.

With the Lifecycle Alliance, Krones assumes responsibility together with the customer for output and life cycle costs in a modularised service agreement.

Ingeniq – the line itself

Our new digital automation architecture makes it possible to connect highly efficient individual machines within a line network and maximise automation: from in-house preform manufacture to high-speed filling of non-carbonated water on the ErgoBloc L right through to autonomous material supply logistics and sustainable packaging solutions – always with a watchful eye on production.

Prefero is the heart of Krones’ preform system. The injection moulder is designed as a hybrid machine with an electrical mould movement and is impressive not only with a best-in-class lock-to-lock time of just 1.9 seconds (400 t). Thanks to an integrated energy recovery system, it also uses up to 20 per cent less energy overall than similar machines from competitors. The Prenexo conveyor and buffer system ensures smooth, efficient material flows between the Prefero injection moulder and the Contiform stretch blow-moulder – it is reliable, secure and container-friendly and improves preform logistics. With it, the two machines can be directly block-synchronised, thus increasing the degree of automation and making the production line more compact, efficient and flexible.

The ErgoBloc L is in a league of its own when it comes to performance per square metre. The wet-end block achieves outputs of up to 100,000 containers per hour – on a footprint that is up to 70 per cent smaller than that of a conventional line. Stretch blow-moulding, labelling, filling and capping are all faster and less complicated thanks to AI-driven process optimisation and quality assurance and a direct connection to the autonomous material handling systems.

Autonomous material handling for maximum efficiency

Whether it’s the inclusion of robotics in a filling line, centralised receiving and unpacking of raw materials, or the use of line management tools to enable operator-machine communication, the flexibility, efficiency and precision of our autonomous material handling systems help our customers automate their work flows and optimise their processes. One example of such an application within the Ingeniq line is the fully automatic reloading, preparing and splicing of label reels without any manual intervention on the operator’s part.

Efficient end-of-line solutions for every requirement

A customised, sustainable packing system rounds out the line: The fully automatic Variopac Pro packer, for example, easily adapts to any and all packaging trends. Whether it’s pads, trays or wrap-around cartons, with or without film or “only” film-wrapped – the different models of the Variopac Pro cover a large number of packaging options. The machine’s modular construction makes it flexible enough to handle a wide variety of packaging configurations. The Variopac Pro takes any changes in packaging in its stride.

Meanwhile, Modulpal Pro series robots open up an abundance of possibilities for palletising and depalletising. Depending on the task at hand, the individual modular components can be combined as needed: for example, to create palletising specialists that are super-fast, especially gentle on products or highly flexible – or even all three at once.

Ingeniq – digital access

The key to digitally networking existing machines or complete lines is the “Connect and Secure” package. With Connect hardware installed, secure digital access is established that makes it possible to enter the networked world of the production line. The line becomes part of Krones’ digital world – visible, connected and remote-maintenance-enabled. Through the central Krones.world platform, both the customer and Krones have 24/7 access to relevant production data. The combination of digital tools, know-how and collaborative partnership makes it possible to reliably and securely achieve the agreed-upon performance in a joint effort. Compliance with legal requirements such as the Cyber Resilience Act, NIS2, and the EU Data Act is also ensured. At the same time, the solution is open to future technology applications and extensions.

Ingeniq – our alliance with the customer

An alliance is a pact, a partnership between individuals and/or organisations pursuing a common goal, in which both parties contribute to its attainment. It is based on trust, dependability and accountability. With the Lifecycle Alliance built into Ingeniq, Krones is committing to just such a partnership with the customer. The aim is to ensure that the agreed-upon level of line efficiency is reached through a joint effort.

Krones’ contribution looks like this:

- Performance: Increase output and production reliability

- Maintenance: Reduce operating costs and downtimes

- Availability: Dependable and connected

With the right selection of – and in this case built-in – service products for Ingeniq, customers will be able to substantially reduce their operating costs and be assured of efficient, reliable production for the long term. That is because all Krones services are optimally aligned and can be adapted flexibly to meet each customer’s specific requirements. To accomplish this, Krones offers individually configurable service packages (modular service agreements) and personal consultations with our experts.

Ingeniq – The advantages at a glance

With Ingeniq, Krones presents a line concept for the future that is setting new standards:

- Maximal availability and output

- Minimal and calculable operating costs

- Maximal automation, including digital integration

- Focussed sustainability

- Lower total cost of ownership

“We’re starting the new line concept of the future with a version that fills non-carbonated water into PET containers – but that is just the beginning. Additional container types and product categories will follow. With Ingeniq, Krones is transforming itself from a machine manufacturer into a comprehensive partner for successful production, working together with each customer,” is how Markus Tischer wraps up the presentation of the new line concept at drinktec 2025

Download

Dr. Anne-Kathrin Bräu

Peter Mörtl