Saving resources with the Krones sustainability programme enviro

Achieving more by using less: The call for ecologically efficient production has

long reached the industrial goods sector.

And this for good reason: On the one hand, legislative bodies and consumers

are focussing more and more on using production equipment that uses less

resources. On the other hand, they also offer their operating companies huge

benefits - but obviously only if they do not affect performance or profitability.

This is why the cumulative innovative strength of Krones development work is

invested in enviro machines. Only this way, we can meet our own expectations:

and this is, to equip the beverage and food industry with future-oriented

technologies which will enable high-performance production which saves

resources at the same time over many years.

At a glance

The Krones enviro sustainability programme ...

- has received certification from the technical inspection authority TÜV SÜD, an independent appraiser.

- has been consistently extended to cover the entire portfolio since 2008.

- is already utilised in the development of new products.

What is enviro?

Basic conditions

enviro is …

- a certified management system.

- an inherent part of Krones product development and services.

- an objective standard for

- energy efficiency

- media efficiency and

- environmental compatibility.

The result

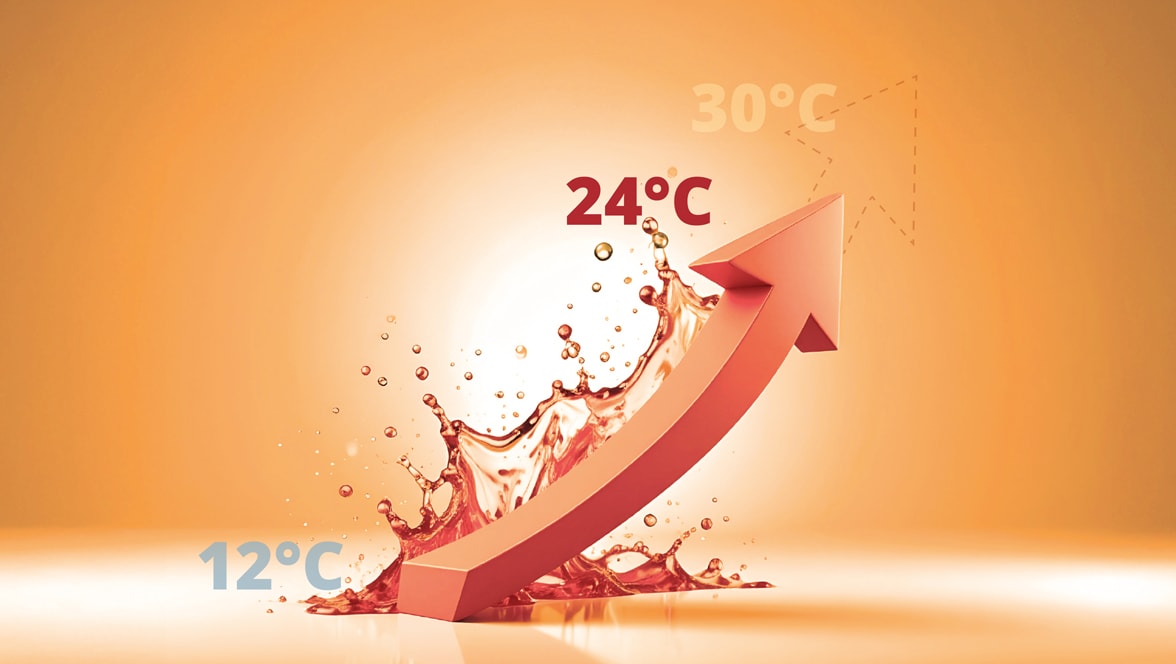

enviro has an effect on all our product developments, services and solutions. Optimum consumption data with regard to energy and media efficiency of both existing and new lines in breweries and beverage plants are part of the Krones day-to-day tasks.

Why enviro?

Because sustainable production has many benefits!

The enviro story of success

Benefits to you

Best available technology

- The components for saving resources included in our machines are based on the latest developments and incorporate energy-efficient and media-efficient technologies.

- Technological progress is continually taken into consideration in the enviro process.

Traceable savings of resources

- The objective evaluation process verifies the resource savings achievable with the enviro machines.

- The enviro system evaluation process also makes it possible to check the ecological efficiency of processes performed on more than one machine, such as process technology.

- The enviro design stands for particularly environmentally friendly packaging.

Use of environmentally sound media

- The use of enviro machines will always prevent materials and media which are harmful to the environment. We will be only too pleased to provide you with relevant documentation.

Optimum consumption data

- enviro flows into all Krones product developments, services and solutions.

- Results are optimal consumption data with regard to energy and media efficiency of existing and new lines.