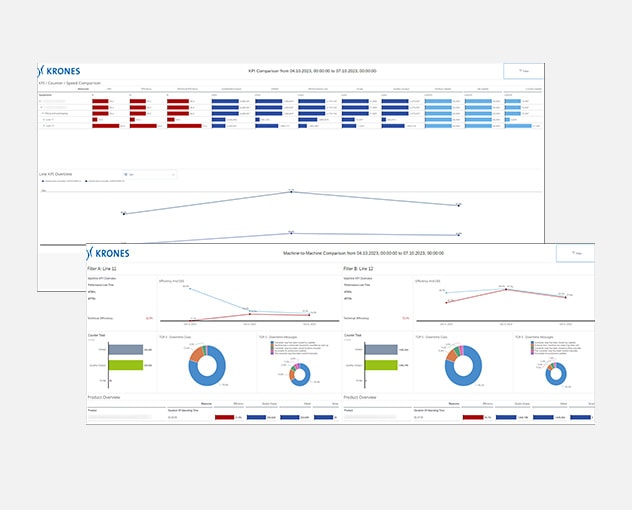

Scalable, integrated and flexible analyses of your line

Utilise the comprehensive options that Integrated Analytics offers as a business intelligence solution specifically for filling and packaging analyses. The software always provides you with the correct solution – whether it be prefabricated reports or even reports customised to meet your needs and which you can generate yourself with just a few mouse clicks. This allows you to precisely define which parts of your production still have optimisation potential and where you can start taking action in order to increase performance and reduce manufacturing costs.

At a glance

- Enhanced reports on line output based on the data provided by Advanced Analytics

- Pre-defined and self-configurable reports

- Reports at corporate level for internal benchmarking

- Type-based analysis of the line output

- Analysis of historical data for deriving patterns and trends

- Integration of external systems

Requirement: Advanced Analytics must be installed in the line (or lines) as data source.

- Combining and contextualisation of data

- Reports customised to meet individual requirements

- Analysis of historical data

- Customised standard and ad-hoc reports

- A range of options for data illustration (diagrams, correlation data, cluster diagrams)

- Combining and contextualisation of data

- Reports customised to meet individual requirements

- Analysis of historical data

- Customised standard and ad-hoc reports

- A range of options for data illustration (diagrams, correlation data, cluster diagrams)

- Reports at corporate level for benchmarking the most important line key figures

- Comparative analyses of the performance per type

- Customised reports either already preconfigured by Krones or self-configurable

- Integration of external data sources, for example from the warehouse management or quality management system

- Reports at corporate level for benchmarking the most important line key figures

- Comparative analyses of the performance per type

- Customised reports either already preconfigured by Krones or self-configurable

- Integration of external data sources, for example from the warehouse management or quality management system

Supporting decisions at management level

Benefits to you

Cost-efficiency

Cost drivers for production downtimes and energy and media consumptions are identifiedand continually reduced.

Time savings

Optimise your time requirements thanks to the fast and comprehensive processing of all data.

Global availability

Use Integrated Analytics 24/7 –regardless of your location and selected end device.

Increase in the Overall Equipment Effectiveness

Obtain an overview of machine data and KPIs and thus create the foundations for increasing your Overall Equipment Effectiveness.

Transparency

Integrated Analyticsaggregates all the relevant state and process data from the available reports for your productionline.

Overview

The system translates a large amount of complex information about your line into informative key figures and thus makes it possible to develop sound actions.