Filling made easy: Quicker, faster, foam-free

Faster filling – without foaming

Time is money – that is the motto for the new Modulfill VFS-M with PFR valves. Not only the duration of the filling process, but also the air consumption and space requirement have been reduced – which in turn has a positive effect on your budget. And thanks to its new, infinitely adjustable PFR valve, the filler scores plus points in terms of product quality. The flow speed can be exactly adjusted to suit the various products: Foaming due to excessively fast filling or wasted time due to excessively slow filling are a thing of the past.

At a glance

- Fast filling of CSD, juice and water

- Infinitely adjustable PFR filling valves for optimum flow speeds

- Reduced number of components due to the optimised interface with the mixer

- The carbonation tank of the integrated mixer is also the feed tank to the filler

The design

New development of the Contiflow mixer

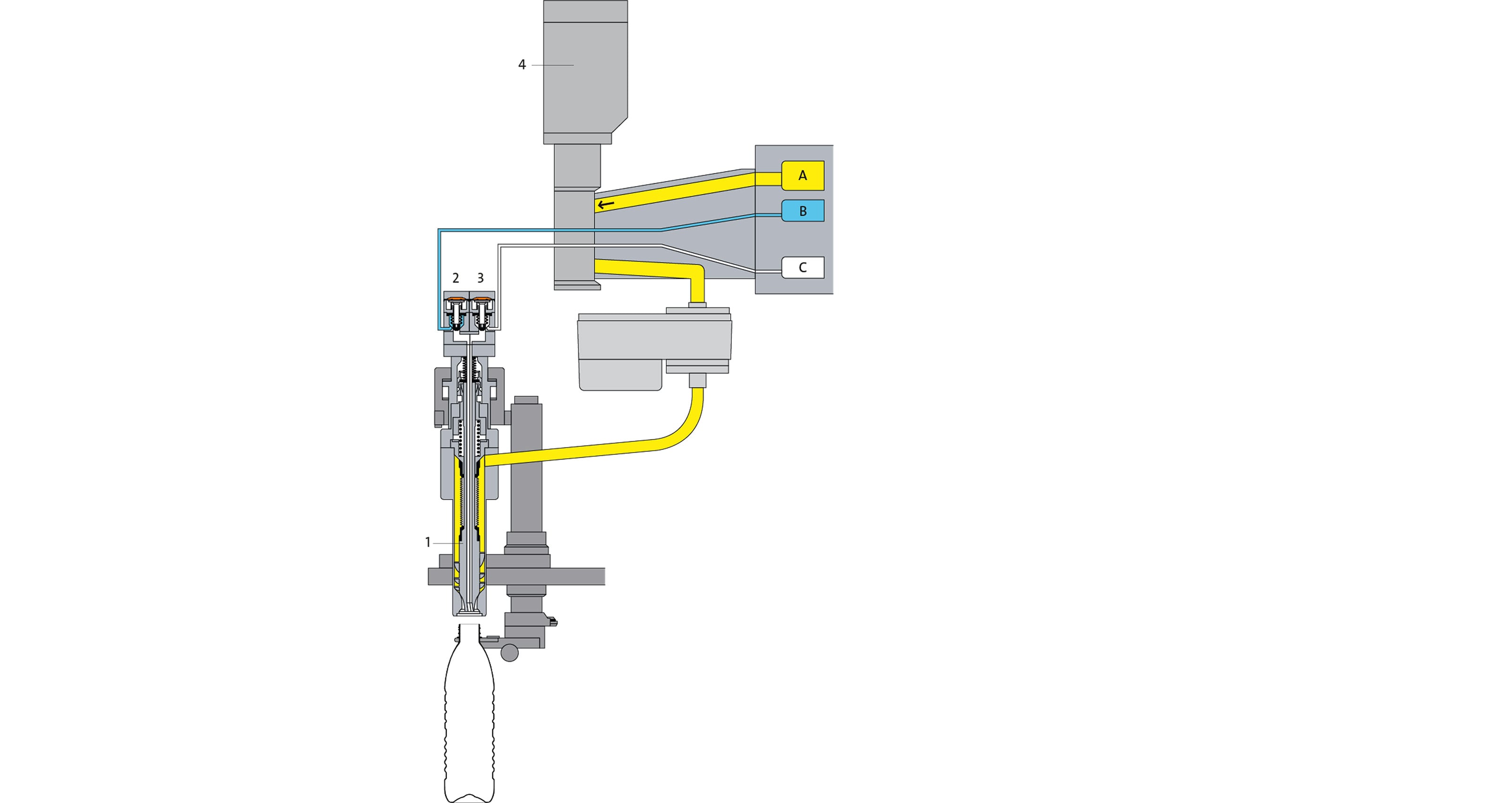

The PFR valve

Fast or slow – there are only two filling speeds in conventional valves. The PFR valve is infinitely adjustable, which has a positive effect on the filling quality: This enables optimum adjustment of the flow rate to suit the particular product properties. Foaming beverages due to excessively fast filling or loss of time due to excessively slow filling are a thing of the past.

New: Electronic controller integrated directly in the valve

For the first time, the PFR valve provides an innovation which pays off, especially with regard to space requirements. To decentralise the power supply to the electronics, the complete control block is now directly integrated in the valve. Omission of a large electronics cabinet.

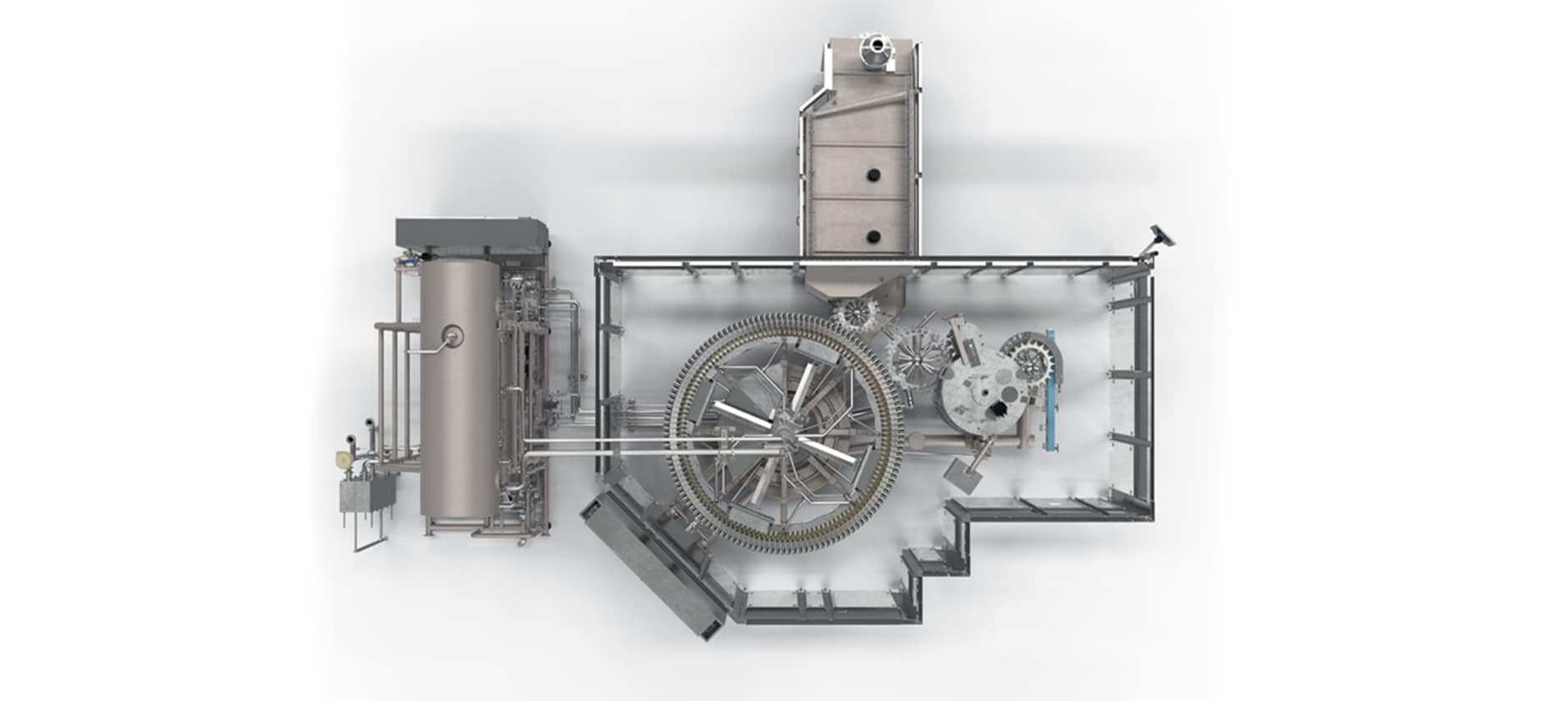

Integrated mixer

With the Modulfill VFS-M, the "M" stands for "Mixer" – which is directly connected to the filler. The product is directly fed via the raised carbonation tank into the manifold. The conventional filler bowl is no longer required.

Benefits to you

Highly precise dosing of syrup and CO2

- Thanks to the high-precision dosing process the syrup consumption in the Contiflow is reduced by up to 0.2 percent (as compared to conventional systems). This reduces the operating costs and your new investment will pay off within a short time.

Faster filling speeds

- The direct connection between the Modulfill VFS-M and the Contiflow mixer positively affects the filling duration. The integration in conjunction with the raised tank enables up to 250 millilitres to be filled per second. The block also reduces the loss of product.

Benefits to you

Enhanced product quality

The new PFR valve enables optimum adjustment of the filling speed to suit the particular product properties. Products which tend to foam excessively can also be processed.

Increased output

The filler operates without lifting cam, which increases the filling angle: This, in turn, increases the output for the same line size. Filling CSD beverages with a PFR valve, for instance, will increase the annual output by up to 25 percent, that is 72 million bottles (based on 0.5 litre bottles and a pitch diameter of 4,320 mm).

Improved cleaning

The CIP cups automatically swing into place using a magnet. This contact-free process without pneumatic components optimises the hygienic conditions and enables the installation of more filling valves on a pitch diameter.

Saved energy and raw materials

The PFR valve operates electronically. This saves 30 percent compressed air as compared to electropneumatic filling.

The Modulfill VFS-M enviro stands for the following

Energy efficiency

- No air dryer required

- 30 percent less consumption of operating air with the PFR valve

- Use of the latest PM drives and pumps