Filling with and without pressure for carbonated and still products

Range of applications

- Still and carbonated high-acid products

- Products with

- Pulp up to 0.4 x 0.4 x 0.4 millimetres

- Fibres up to 2 x 10 mm

Technical features

- Method of filling

- For still products: Pressed-on, pressureless

- For carbonated products Pressed-on, according to counter-pressure

principle

- Swirl insert in the valve

- Two different filling speeds

- Inductive flow meter for determining the quantity of liquid

- Product feed from above via a sliding ring manifold

- Sterilisation with steam

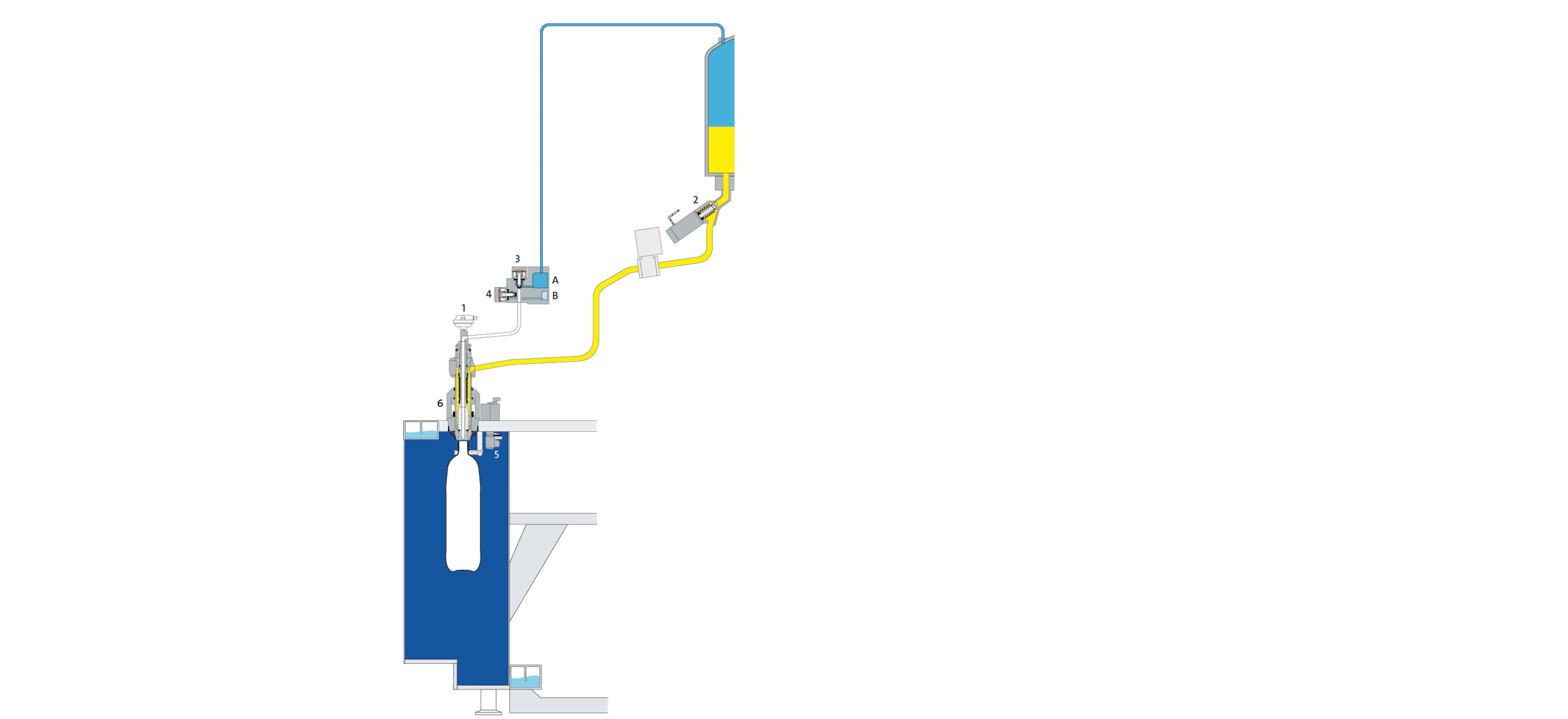

VFS: Volumetric filling, Flow meter, Short tube

Filling vales

Entlastungs- und CIP-Rücklaufkanal

Vorspann- und CIP-Rücklaufkanal

Anpresseinheit

SIP-Kappe

Entlastungs- und CIP-Ventil

Vorspann-, Rückgas- und CIP-Ventil

Umschaltventil schnell/langsam

Pneumatikzylinder Ventilkegel

Aseptischer Bereich

Hydraulic seal “Liquid seal system”

Valve stem

Inductive flow meter

Central bowl

Benefits to you

- Flexible use for different products

- Non-turbulent, foam-inhibited filling process

- Optimum flow behaviour

- Precise fill quantities

- Minimum product loss

- Quick and media-efficient disinfection

- No CIP distributor needed

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events