The compact solution for can inspection

There's a lot inside

Small on the outside, huge on the inside: The new Cantronic C inspection machine is significantly more compact than its predecessor. However, its slimline surface conceals enormous potential. With its innovative multiple station, it inspects three can areas at once: Flange, base and inner side wall. It can also be extended with deep learning technology - taking quality control in your line to a whole new level.

At a glance

- Space-saving solution for inspecting empty beverage cans

- Compact multiple station for checking the flange, inner side wall and base

- Options:

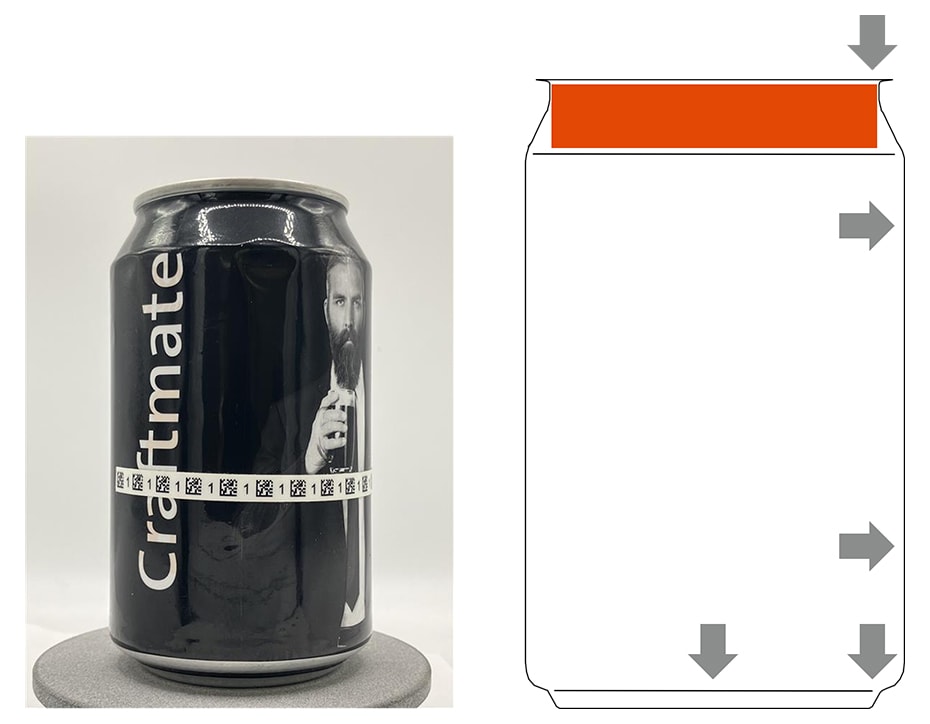

- 4-camera system for 360° inspection in the shoulder area

- 2-camera system for checking the outer side wall and/or design

- Deep learning technology with additional detection options

- Rated output: up to 130,000 cans per hour

C = Compact

Overview

Inspection unit (multiple station): Flange, base, inner side wall

Inspection unit: Outer side wall (optional)

Inspection unit: Inner top side wall (optional)

height adjustment system (electrical version optional)

Basic unit with 21.5 '' touch-screen and integrated cooling unit

Integrated rejection unit Ecopush

Structure

Faulty test containers are used to check the inspection units for proper operation.

Technology used

- Multi-functional test container with 2D code strip

- Test container 1: Base centre, inner side-wall bottom, beading

- Test container 2: Base border, inner side-wall bottom, beading

Method of operation

- The program is called up automatically after a specified number of containers or time

- Results displayed after successful/unsuccessful through passage

- All of the results are saved automatically with the date and time

Benefits to you

- Very high product safety

- Simple and low-cost manufacture of the test cans

Benefits to you

Compact design

With its multifunctional multi-station and compact machine design, the Cantronic C delivers high performance in a small space.

Precise quality control

The high-resolution basic camera detects even the most minute dirt and irregularities. The additional camera unit enables you to even detect dirt in the neck area which is very hard to find.

New inspection options

The machine can optionally be equipped with the Deep-Learning technology. As the Cantronic AI, it recognises defects that remain hidden from conventional systems and delivers reliable results even with different inner wall coatings.

High line efficiency

Damaged or deformed cans pose a significant safety risk to the filling line which may result in machine standstills and even machine damage. The Cantronic C sorts out all those "risky" cans, thus increasing the overall line efficiency by approximately 5 %.

Remote diagnostics and maintenance

The Krones Remote Service provides you with round-the-clock expert advice and support. If required, a Krones service engineer can access your inspector via a secure data link. Parameter settings, software updates and fault analyses can thus be carried out quickly, cost-effectively and with absolute security.

High degree of operational reliability

The Cantronic C automatically rejects fallen-over containers and features a continuous self-monitoring function. Malfunctions and faulty operations are thereby prevented from the very beginning.