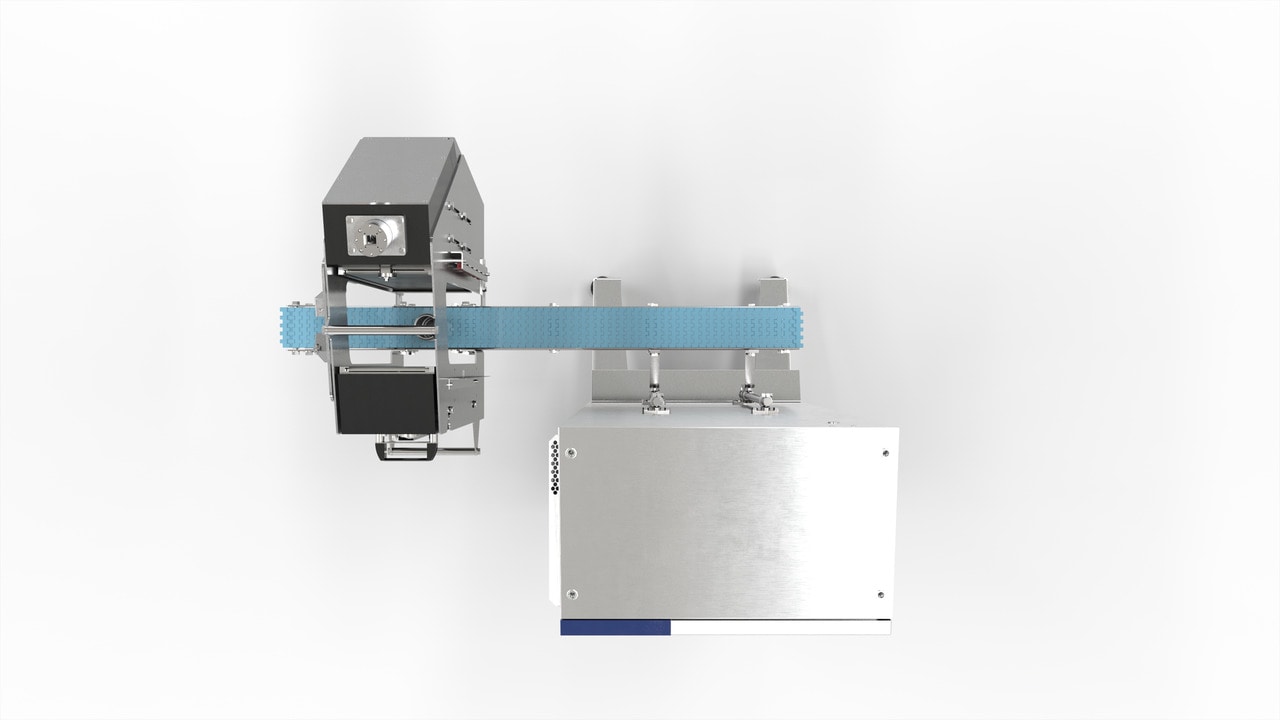

The high-precision container sorter

Sorts unerringly –without leaving marks

Height, colour, contour, neck finish or cap: Regardless of the characteristics of your containers, the Sekamatwill recognize them, and reject all the other ones unerringly. A camera is used for contact-free inspection.

At a glance

Possible sorting criteria:

- Container contour

- Diameter

- Container height

- Neck finish contour

- Colour

- Cap presence

Additional inspection units for:

- Label colour

- Partially filled containers

- ACL

- Cap colour

Technical features

- Colour camera

- LED lighting

- Output:

- Up to 72,000 containers per hour with Ecopush rejection unit

- Up to 50,000 containers per hour with Varioglide rejection unit

Safety management: Password protection with transponder

- Production is started once an authorised person logs on

- Identification using transponder technology

- Password protection with automatic log-out function

Benefits to you

Thorough sorting, higher efficiency

The high-precision sorter provides an optimum sorting result for each bottle. As a result, the line efficiency is also increased, as containers of other types are rejected in front of the washer.

Ease of operation

Mechanical adjustment is not required for type change-overs. Faulty operation is thereby almost excluded.

Low-cost procurement and operation

The Sekamat scores with low investment costs and also proves to be quite economic during operation: Its LED lighting units ensure a service life of at least ten years and never require maintenance during this period.

Remote diagnostics and maintenance

The Krones Remote Service provides you with round-the-clock expert advice and support. If required, a Krones service engineer can access your inspector via a secure data link. Parameter settings, software updates and fault analyses can thus be carried out quickly, cost-effectively and with absolute security.