Block synchronisation concepts in the smallest of spaces

Compact, sustainable, revolutionary

Block synchronisation concepts are a valuable alternative to individual machine arrangements in many respects: lower investment costs, reduced space requirements, less noise during production and easier system operation.

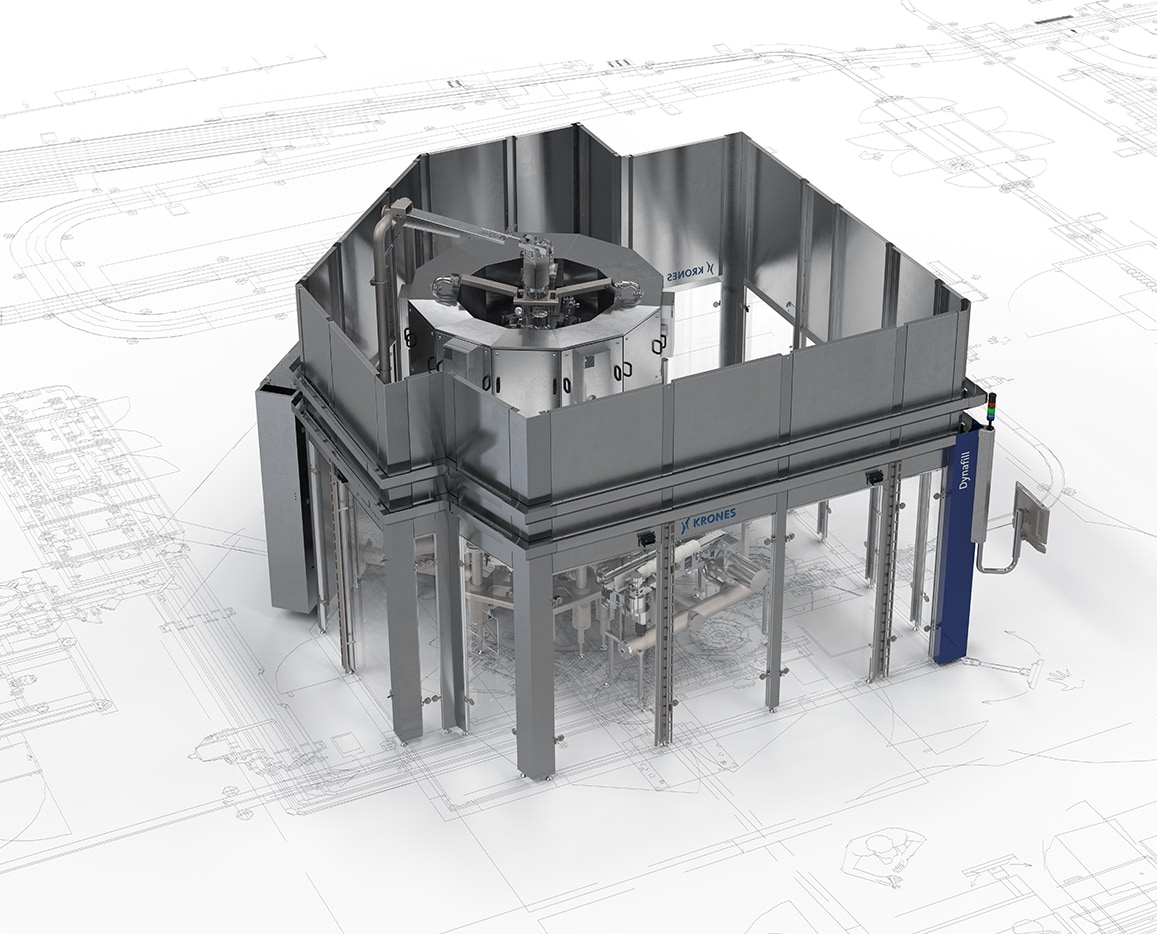

In the Dynafill Bloc FL* the new pitch-adjusting starwheel is used to connect the filler to the labeller. The concept also includes a long stator linear motor starwheel at the Dynafill infeed. This enables more bottle circulations, a quieter production environment and the system requiring less space.

*FL: Filling, Labelling

More bottle circulations, a quieter production environment and less space required for fillers or rinsers. Krones is turning a vision into reality by employing a long stator linear motor in the infeed starwheel. In the future, this innovative, highly flexible concept will replace the familiar worm infeed and back-up control section.

At a glance

- Can be used for non-returnable and returnable glass bottles

- Modular integration into base handling machines at the infeed upstream from rinsers or fillers

- Replaces conventional infeed starwheels including infeed worm

- Synchronous control of the container conveyor and filler instead of back-up control:

- the back-up control section is omitted

- Reduced bottle stress and lower noise levels

- Monotec design

More bottle circulations, a quieter production environment and less space required for fillers or rinsers. Krones is turning a vision into reality by employing a long stator linear motor in the infeed starwheel. In the future, this innovative, highly flexible concept will replace the familiar worm infeed and back-up control section.

At a glance

- Can be used for non-returnable and returnable glass bottles

- Modular integration into base handling machines at the infeed upstream from rinsers or fillers

- Replaces conventional infeed starwheels including infeed worm

- Synchronous control of the container conveyor and filler instead of back-up control:

- the back-up control section is omitted

- Reduced bottle stress and lower noise levels

- Monotec design

Revolutionary filling technology as part of a resource saving brewery of the future. Released cooling energy that can be used intelligently in another area. A reduced microbiological risk during filling. Last but not least: Filling and capping in a single unit, in less than five seconds, and this at ambient temperatures. When it comes to the Dynafill, the list of true unique selling points is long – and it soon becomes clear: This machine makes it possible to achieve completely new energy and line concepts.

At a glance

- Combined filling and capping process on one single machine

- Maximum speed: 80,000 containers per hour

- The Dynafill enables the following:

- Filling temperatures of up to 30 °C

- A reduced energy requirement in the entire brewery

- Innovative line concepts

Revolutionary filling technology as part of a resource saving brewery of the future. Released cooling energy that can be used intelligently in another area. A reduced microbiological risk during filling. Last but not least: Filling and capping in a single unit, in less than five seconds, and this at ambient temperatures. When it comes to the Dynafill, the list of true unique selling points is long – and it soon becomes clear: This machine makes it possible to achieve completely new energy and line concepts.

At a glance

- Combined filling and capping process on one single machine

- Maximum speed: 80,000 containers per hour

- The Dynafill enables the following:

- Filling temperatures of up to 30 °C

- A reduced energy requirement in the entire brewery

- Innovative line concepts

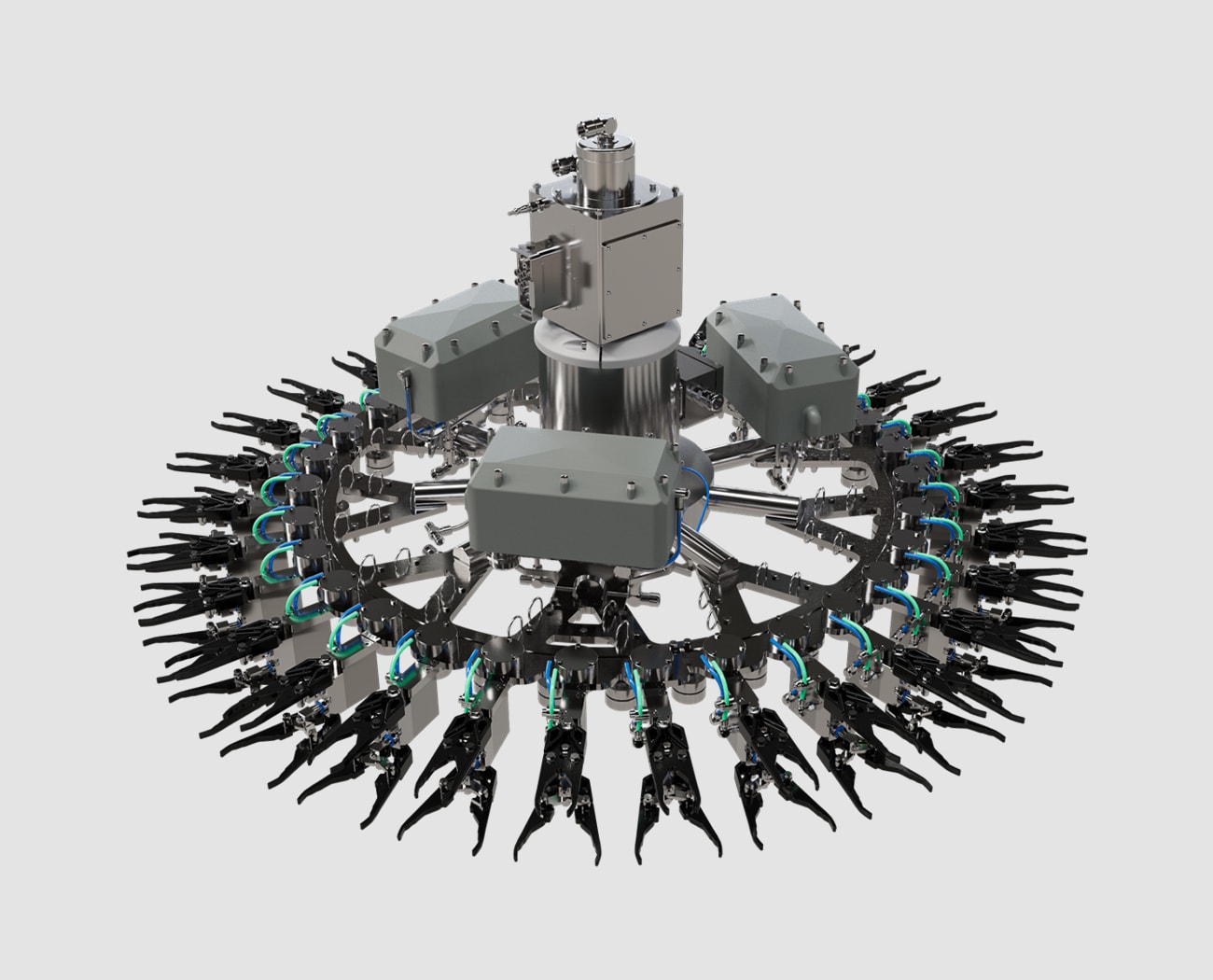

The manipulation cam in the pitch-adjusting starwheel makes it possible to change the pitch of two machines, for example from a filler to a labeller

Technical description

- Pitch-adjusting starwheel on the basis of the well-known block synchronisation technology for neck handling

- Pneumatic gripper units for maximum flexibility

- Omission of handling parts thanks to the MultiGuide Base multifunctional gripper starwheel

The manipulation cam in the pitch-adjusting starwheel makes it possible to change the pitch of two machines, for example from a filler to a labeller

Technical description

- Pitch-adjusting starwheel on the basis of the well-known block synchronisation technology for neck handling

- Pneumatic gripper units for maximum flexibility

- Omission of handling parts thanks to the MultiGuide Base multifunctional gripper starwheel

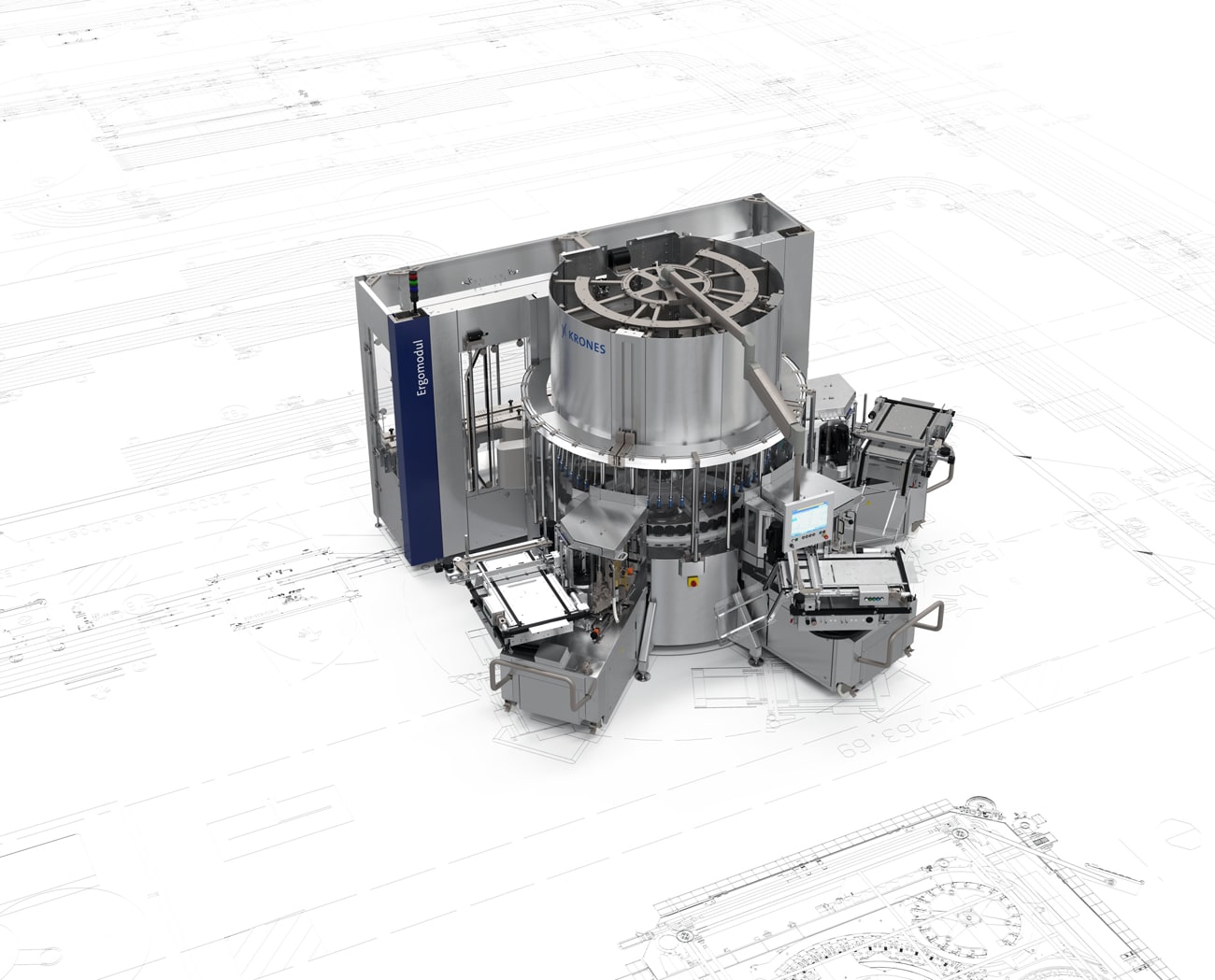

The EM* series of Krones labelling systems offers the perfect machine for every application. It offers three main machines, six table diameters, seven labelling station types – and it offers numerous options for combining the individual elements with each other. The Ergomodul is its technological spearhead: A lean, highly efficient machine for ultra-flexible applications.

At a glance

- High-tech model of the Krones EM-series

- Columnless machine with interchangeable labelling stations

- Labelling method and speed:

- Pre-cut labels with cold glue up to 72,000 containers per hour

- Pre-cut labels with hotmelt up to 72,000 containers per hour

- Reel-fed labels with hotmelt up to 100,000 containers per hour

- Self-adhesive reel-fed labels up to 60,000 containers per hour

The EM* series of Krones labelling systems offers the perfect machine for every application. It offers three main machines, six table diameters, seven labelling station types – and it offers numerous options for combining the individual elements with each other. The Ergomodul is its technological spearhead: A lean, highly efficient machine for ultra-flexible applications.

At a glance

- High-tech model of the Krones EM-series

- Columnless machine with interchangeable labelling stations

- Labelling method and speed:

- Pre-cut labels with cold glue up to 72,000 containers per hour

- Pre-cut labels with hotmelt up to 72,000 containers per hour

- Reel-fed labels with hotmelt up to 100,000 containers per hour

- Self-adhesive reel-fed labels up to 60,000 containers per hour

What the Dynafill Bloc FL enviro does:

-

Increases the filling temperature to up to 30 degrees Celsius

-

Reduces the footprint by up to -40 percent

-

Increases bottle circulations by up to +30 percent

Benefits to you

More compact line layout

The omission of the back-up control section allows for an electronic block synchronisation of the empty bottle inspector and filler or rinser. The connecting conveyors are omitted and both machines are therefore moved closer together. The pitch-adjusting starwheel also allows a filler and labeller with different pitches to be block synchronised in the smallest of spaces.

Returnable glass: Extension of the cycles

The reduced scuffing on the container ensures less wear and tear, thus allowing bottle cycles to be increased and returnable containers to be put into circulation more often than before.

Filling at ambient temperature

The Dynafill enables not only cold but also warm filling of beverages (temperatures up to 30 °C) – the process does not take longer than five seconds in both cases. The filling process remains always stable. The higher filling temperature means brewery energy concepts can be completely reinvented.

Efficiency during labelling

How can you perform a lot with little input? Ergomodul labellers will show you exactly how it is done. Regardless of whether talking about the spare parts management, the footprint, the operator effort or the energy consumption: This complex series has been designed for the maximum efficiency up to the smallest detail.