Stability for aseptically filled bottles

Aseptic nitrogen dosing system

Even thin-walled bottles remain stable in any situation with this method: sterile liquid nitrogen is dispensed into the head space of the filled bottle. The nitrogen evaporates after capping and thereby establishes a stabilising pressure. Whether for labelling, during transportation or on the store shelf: thanks to the NitroAdd Asept, PET bottles are always presented in their best shape.

At a glance

- Precise dosing of sterile liquid nitrogen

- Ideal for sensitive beverages – even in lightweight containers

- Output: Up to 72,000 containers per hour

- Seamless integration in all Krones filler and wet-section blocks

- Media connections and sterile air filter in the filler valve manifold

- Operation on the filler HMI (Human Machine Interface)

- Controlled by the filler PLC – no separate PLC required

- Steam sterilisation of all sterile areas (filter, lines, nozzle)

- Frost protection for the dosing nozzle

- Evaporator and capacitor inside the dosing unit – double-insulated design

- Evaporator with electric heating system – no additional steam lines required

Design

How is the system structured?

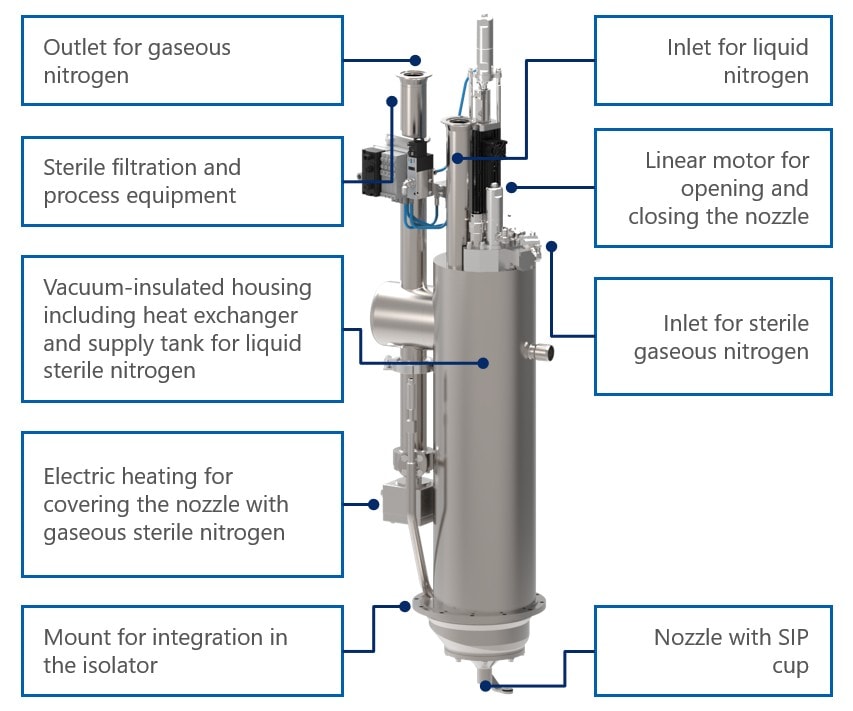

- The NitroAdd Asept comprises two system components:

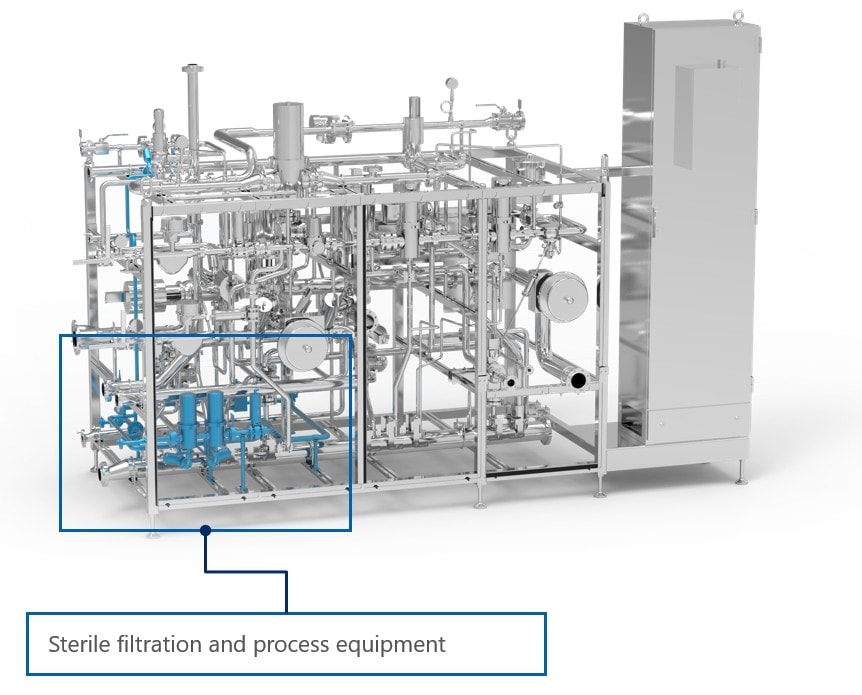

- Unit for the sterile filtration of the gaseous nitrogen

- Dosing system

- The process equipment comprises two sterile air filters connected in series.

- The following components form part of the dosing system:

- Motor and spindle for opening and closing the nozzle

- Connections for sterile gaseous and liquid nitrogen

- Outlet for the gaseous nitrogen

- Vacuum-insulated housing with heat exchanger and supply tank

- Electric evaporator to cover the nozzle (protection against freezing/icing)

Method of operation

- Sterilisation of the entire system with food-grade steam

- SIP cup for reaching the sterilisation temperature

- Temperature sensor for checking the sterilisation procedure

- Drying of the system with warm gaseous nitrogen after the sterilisation process

- The gaseous nitrogen is sterile-filtered and liquefied in a heat exchanger coil.

- Coolant: liquid nitrogen

- The sterile liquid nitrogen is stored in a supply tank.

- The heated sterile nitrogen from the supply tank is used as a protective gas at the dosing nozzle.

- It prevents the nozzle freezing during production

- The liquid nitrogen can be dosed either intermittently or continuously.

- The exact dosing amount and speed are stored in the filling PLC for each bottle format.

The liquid nitrogen in the system is vaporised using heated nitrogen.

- Ensures there is no liquid nitrogen in the system before sterilising with steam

- Prevents the housing from being damaged due to a temperature shock.

Benefits to you

Intelligent exhaust gas handling

The exhaust gas from the unsterile liquid nitrogen, which serves as a cooling medium, is discharged internally through the filler air handling unit. This prevents it influencing the conditions in the filling hall in any way. The exhaust gas from the sterile nitrogen is also used again as a protective gas.

Ultra-slender construction

The nitrogen doser only comprises one single tank. Apart from that, it simply uses the technical equipment of the filler: from the valve manifold to the sterile air filter, all the way to the operator panel and controller. The electric heating used for preheating the sterile nitrogen is also used to protect the nozzle from freezing. This eliminates the need for an additional steam line from the valve manifold to the dosing unit.

Exactly dosed bottle stability

The amount and speed of dosed nitrogen are stored individually for each bottle format in the filler PLC. This ensures that each product has precisely the stability it requires for further processing. You would like to fill your product into material-saving lightweight bottles? NitroAdd Asept makes it possible!

Double-insulated design

The sterile storage tank is housed in the liquefaction container – and is therefore surrounded by a protective layer of liquid nitrogen.