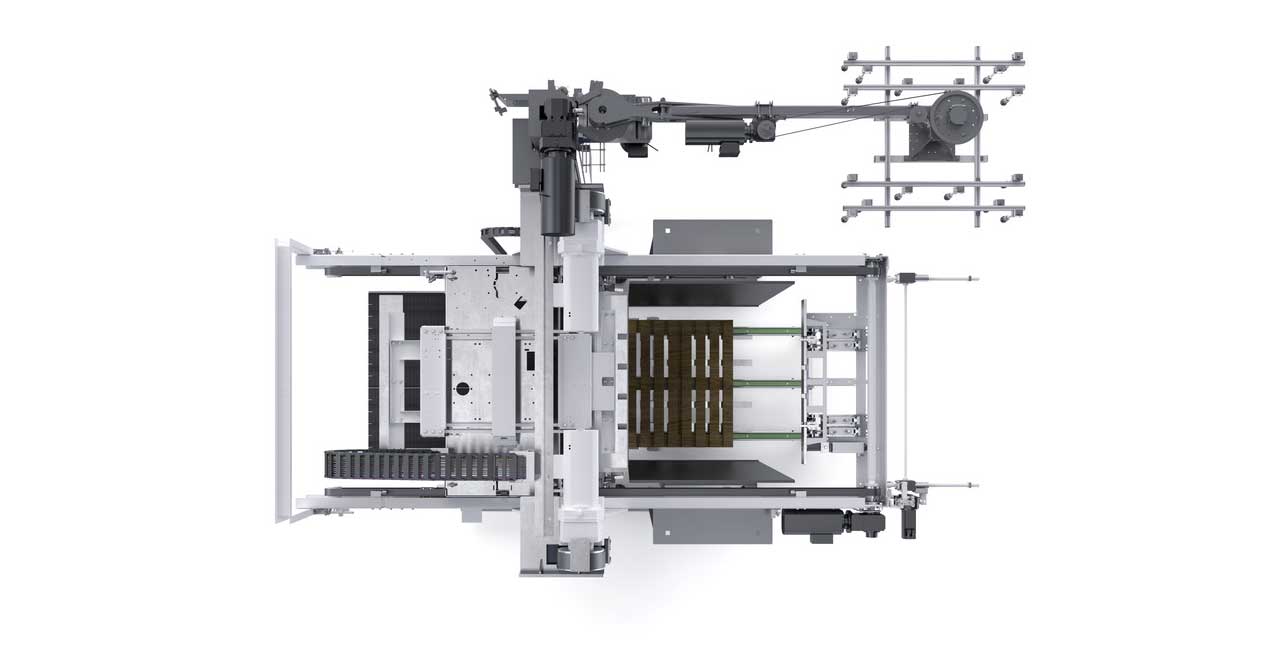

High-performance container sweep-off depalletisers

Fast, efficient and gentle

The reliable and gentle handling of new containers is the Pressant Universal container sweep-off depalletiser’s area of expertise. The machine works with servo drive technology and can therefore be adjusted with great precision to suit the depalletising task in hand. Its modular construction also offers high flexibility when planning into existing line layouts.

At a glance

- Depalletising of cans, glass or PET containers with diameters of between 50 and 200 millimetres

- Handling of pallets with inverted trays, pallets with layer pads and inverted trays or pallets with layer pads and top frames

- Targeted adjustment of the output and layout to suit the line

- Output: Up to 400 layers per hour

- enviro-certified for reduced energy and media consumption

Method of operation

- Conveyance of the unstrapped pallets into the machine

- Detection of the actual height of each top layer using a sensor and continual definition of the optimum stopping point for each layer, also while taking any container tolerances into consideration

- Positioning of the sweep-off unit above the layer and securing of the pallet structure by centring the layer(s) below

- The sweep-off unit holds the top layer in place from all four sides

- Pressant Universal 1N: Transfer of the layer to a layer plate with subsequent transfer to the container discharge table

- Pressant Universal 1A: the layer is transferred to the container discharge table

- A layer pad remover picks up and disposes of layer pads, inverted trays and top frames

Pressant Universal 1N with travelling sweep-off station

Design features

- Modular design

- Height-adjustable sweep-off station

- Automatic adjustment of layer centring unit at the sweep-off unit

- Container discharge table available as a high or low-level option

- Lifting unit with counterweights

- Lifting unit and sweep-off unit driven by servo-controlled motors and maintenance-free toothed belts

- Integrated safety stop feature

- Drop protection for the lifting unit protects persons when entering the safety zone

- Driven by servo-controlled motors

- Programmable logic control

Pressant Universal 1A with stationary sweep-off station

Design features

- Modular design

- Container discharge on the top level

- Container lifting device

- Centring shaft for the pallet stack

- Automatic adjustment of layer centring unit at the sweep-off unit

- Easily exchangeable roller guides on the lifting unit and sweep-off station

- Lifting unit with counterweights

- Lifting unit and sweep-off unit driven by servo-controlled motors and maintenance-free toothed belts

- Integrated safety stop feature

- Drop protection for the lifting unit protects persons when entering the safety zone

- Programmable logic control

Benefits to you

Easily integrated machine concept

Pressant Universal container sweep-off depalletisers are flexible thanks to their modular design: They can be individually adjusted to suit the required output and product range, and are easily integrated in the existing line layout.

Gentle container handling

The servo-controlled drive technology guarantees that the containers can be depalletised gently and reliably. It also contributes to the machine achieving a long service life.

Low energy requirement

The use of counterweights on the lifting column allows the machine’s energy consumption to remain at a low level.

Easy maintenance

Wear-proof toothed belts ensure that the required maintenance is reduced to a minimum.

This is why the Pressant Universal is enviro-classified

- Low energy and media consumption

This product is enviro classified

Top technology for ecologically efficient production

The Krones sustainability programme enviro: top technology for ecologically efficient production.