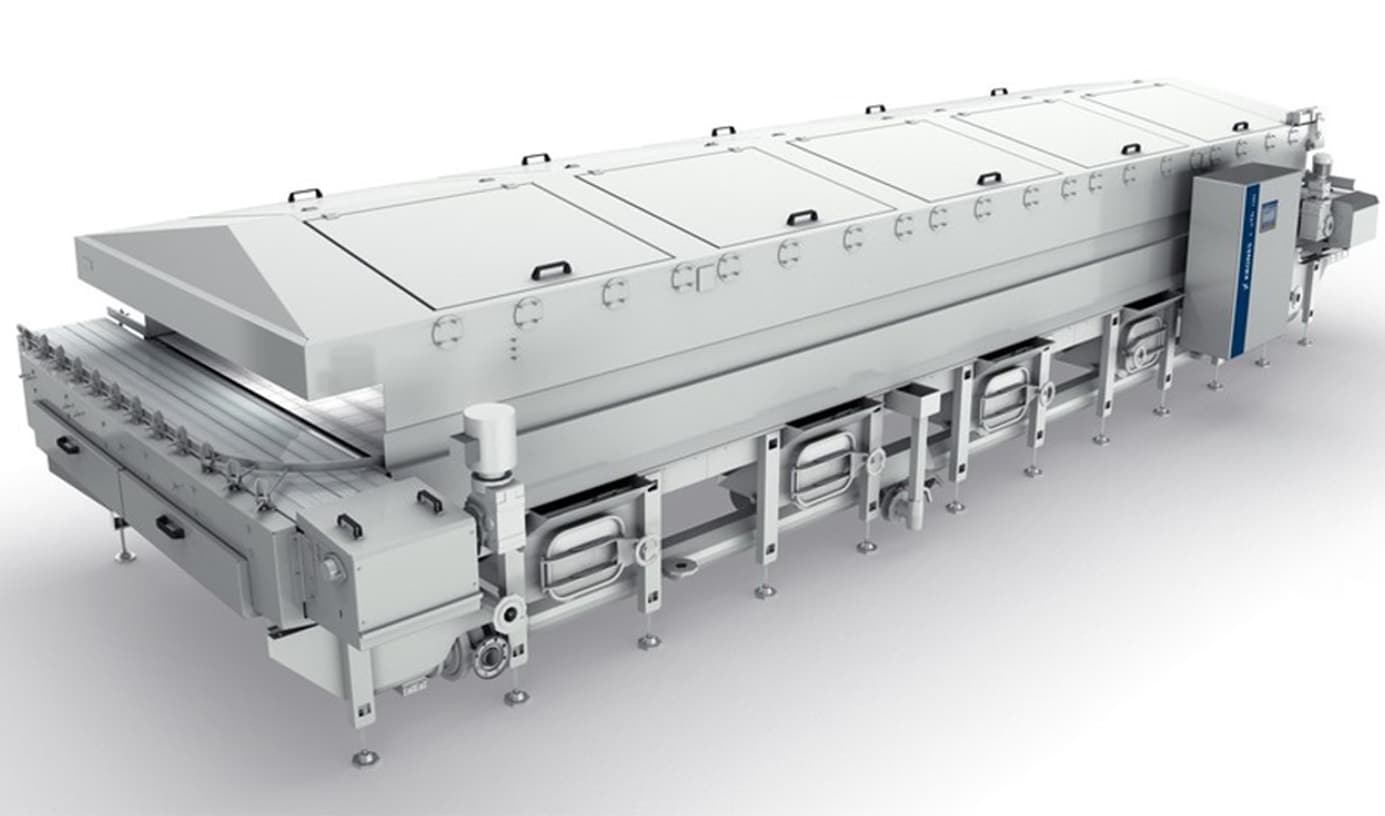

The warmer in Clean Design

Quick and efficient heating of containers

Cold-filled beverages are literally too cool for their packaging. As soon as the containers leave the filler, condensation collects on them. The consequences: soaked containers and transport damage. This can be prevented with the LinaTherm warmer. It is employed right after the filler and it gently adapts the containers' temperature to the ambient temperature. Hence, there are no obstacles to perfect labelling and packaging.

At a glance

- Compact and one-piece warmer, which adjusts the containers to the dew point after filling

- Clean design in stainless steel AISI 304

- Pumps in stainless steel design

- Plastic conveyor Marathon Belt with long service life

- Integrated CHESS heat exchanger system

- Infeed and discharge at a height of 1.2 metres each

Spraying system and transport system design

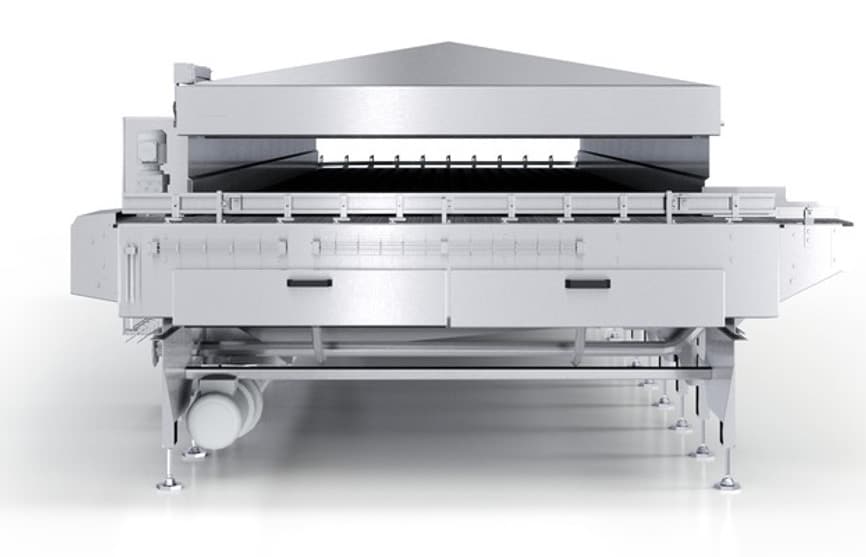

Spraying system

- Even water distribution

- Snap-in spraying system

- Double plug-in sieves to protect the pumps

- Blower covering the machine width for reduced water consumption

Conveyor: Marathon Belt

- Service life of up to 20 years

- Stable and robust structure thanks to its stainless steel frame

- Up to 75 percent less friction due to high-grade roller bearings for the conveyor

- No wear or glide strips

- Optimum transfer properties

- Max. load up to 260 kg/m²

Drive and controller

Frequency-controlled drive system

- Only one main drive (< 0.75 kW)

- No centre bearing, no return shaft

- Drive and bearing outside the machine

Machine controller

- Siemens S7 or Allen Bradley PLC

- Zenon visualisation system on 5" touch-screen with adjustable parameters, e.g., for

- Zone temperatures

- Output

- Bottle diameter

Benefits to you

Ideally tempered containers

The LinaTherm safely adjusts the temperature of cold filled products to the ambient temperature and thereby ensures that no condensation develops which would impair the labelling and packaging quality.

Compact design

All machine areas and components are easily accessible. Required maintenance work can be performed quickly.

Components with long service life

High-quality materials are installed in the warmer This goes for the drive elements and the conveyor elements as well as for the housing and the pumps, which are completely made of stainless steel. This reduces the risk of corrosion and ensures a longer warmer service life.

Plug and play

All LinaTherm components are completely pre-assembled and tested already at the Krones plant. The subsequent installation is done at the site via plug and play. This way, you can use your warmer fully within very short time!

Clean design

The Clean Design with plane side walls, inclined drip pans, and central draining provides ideal, hygienic conditions and guarantees that no water remains in the machine. As an option, you can also include controlled dosing systems for disinfection media in the LinaTherm.