High flexibility with wrap-around labelling with pre-cut labels and hotmelt

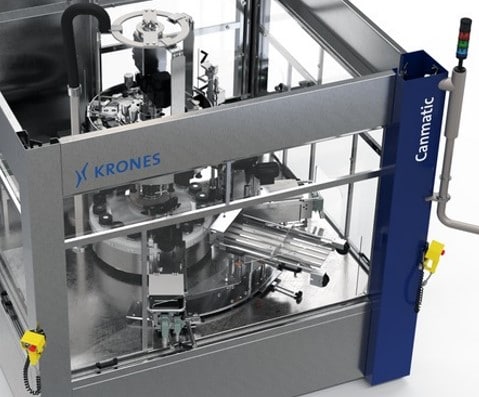

For container decoration with hotmelt and cut wrap-around labels, the Canmatic is setting standards already for many years. The machine has been designed as rotary machine and is equipped with a precisely operating labelling station. With regard to efficiency, accuracy and speed, the Canmatic absolutely takes a leading position.

At a glance

- Wrap-around labelling of cylindrical and specially shaped containers

- Precise container fixing using centring bells and container plates

- High-speed access to the user interface through individual transponders

- Remote maintenance is available as an option

Method of operation

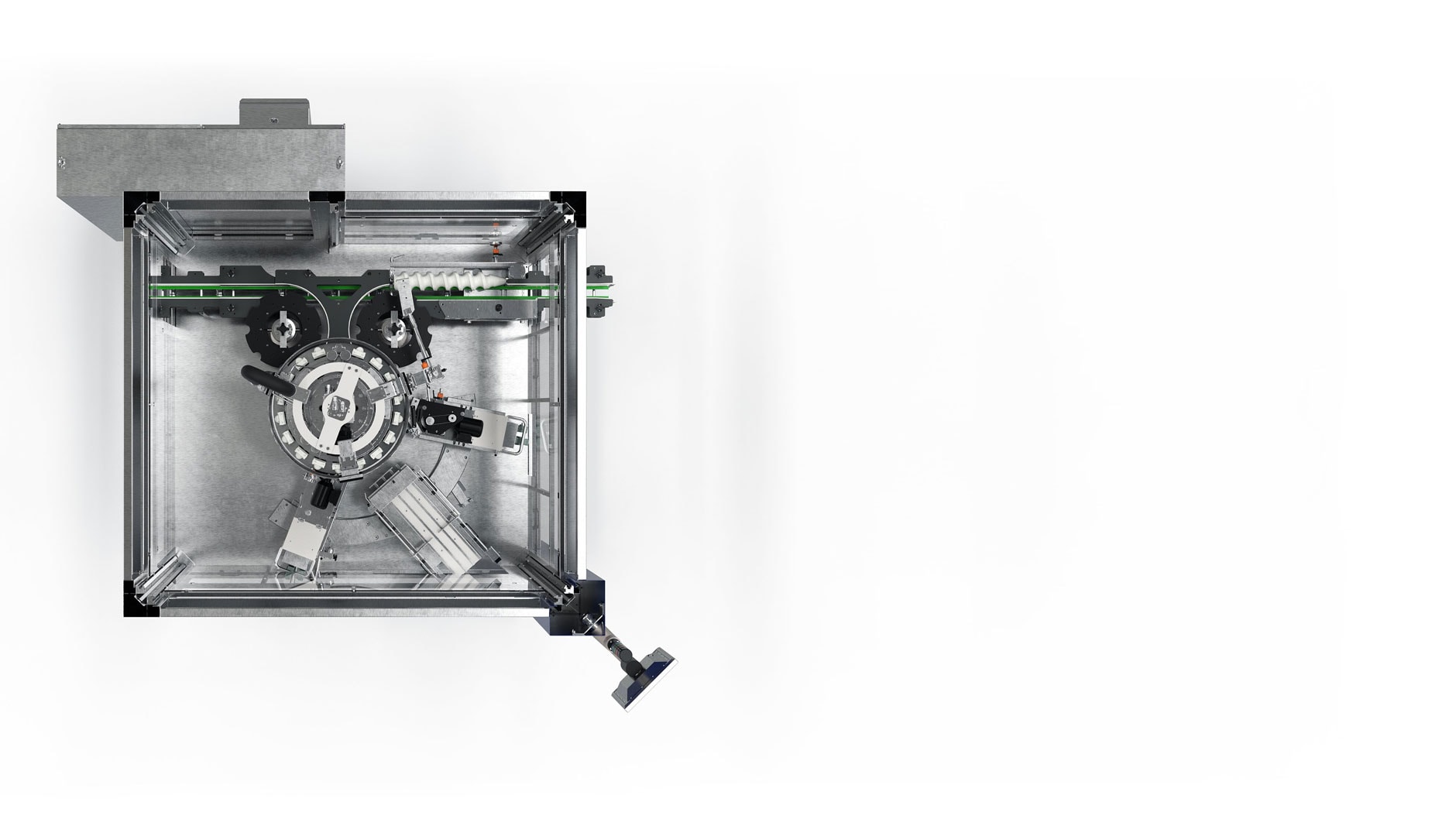

The labelled containers are collected by the discharge starwheel and transferred to the conveyor.

The second hotmelt unit applies glue to the end of the label. The label is glued on the overlap.

The container picks up a label from the label magazine with a glue strip.

The first hotmelt unit applies a vertical strip of glue to the container.

Here they are firmly held and centred between the container plates and the centring bells.

The infeed starwheel transfers the containers to the rotating container table.

An infeed worm spaces the incoming containers to the correct machine pitch.

Two variants for wrap-around labelling

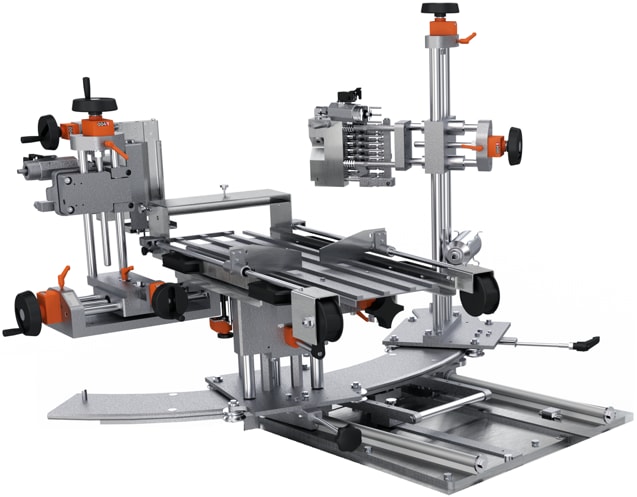

Canmatic CL labelling station with glue rollers

- Output range of 3,000 to 72,000 containers per hour with only one labelling station, depending on the label length

- Two independently operating hotmelt units with glue roller

- Consistent leading and trailing-edge gluing quality

Technical features and benefits

- Two independently operating hotmelt units

- Robust mechanical design

- Individual adjustment of the glue temperature on the hotmelt units

- Exact regulation of the glue film thickness using a scaled micrometer adjusting screw

- Consistent leading and trailing-edge gluing quality

- Magazine for approx. 9,000 wrap-around labels, position adjustable

- User-friendly label refilling

- Overlapping correction possible during production

- Mechanical technology for demanding framework conditions (power fluctuations, dust, etc.)

- Adjustment of the axes with a handwheel including register

- Quick and repeat accurate change-over of the decoration

CL = Classic

Canmatic CL labelling station with glue spraying system

The leading edge is glued via individual nozzles, the trailing edge is glued using a continuously slotted nozzle.

- Output range of 3,000 to 64,000 containers per hour with only one labelling station, depending on the label length

- Reduced cleaning times as well as reduced energy and media consumption thanks to closed gluing systems

Technical features and benefits

- Individual nozzles for leading-edge gluing, continuous slotted nozzle for trailing-edge gluing

- The amount of glue applied can be individually adjusted to suit the container and label

- Closed gluing system

- Reduced cleaning times

- Considerably longer cleaning intervals

- Lower consumption of energy and media

- Significant glue saving of up to 50 percent (in comparison to the conventional system)

- No glue roller as a handling part

- Saving several minutes for each change-over process

- Contact-free glue application with nozzles

- No cleaning of glue rollers required

CL = Classic

Benefits to you

User friendliness

The Canmatic features ease of access and ease of operation.

Low glue consumption

Only two narrow strips of hotmelt are required for labelling, one at the leading edge and the other one at the trailing edge of the label.

High performance

Both Canmatic variants cover all requirements for precision labelling from the low to the maximum output range.

High labelling precision

Fixation of containers between the centring bell and the container plate ensures a highly precise container decoration.

Maximum availability

The machine is based on a robust labelling technology tolerating faults.

Time savings

Only short change-over times needed when changing container or label type.

Future-proof

The Canmatic can be retrofitted and converted also after many years of operation.