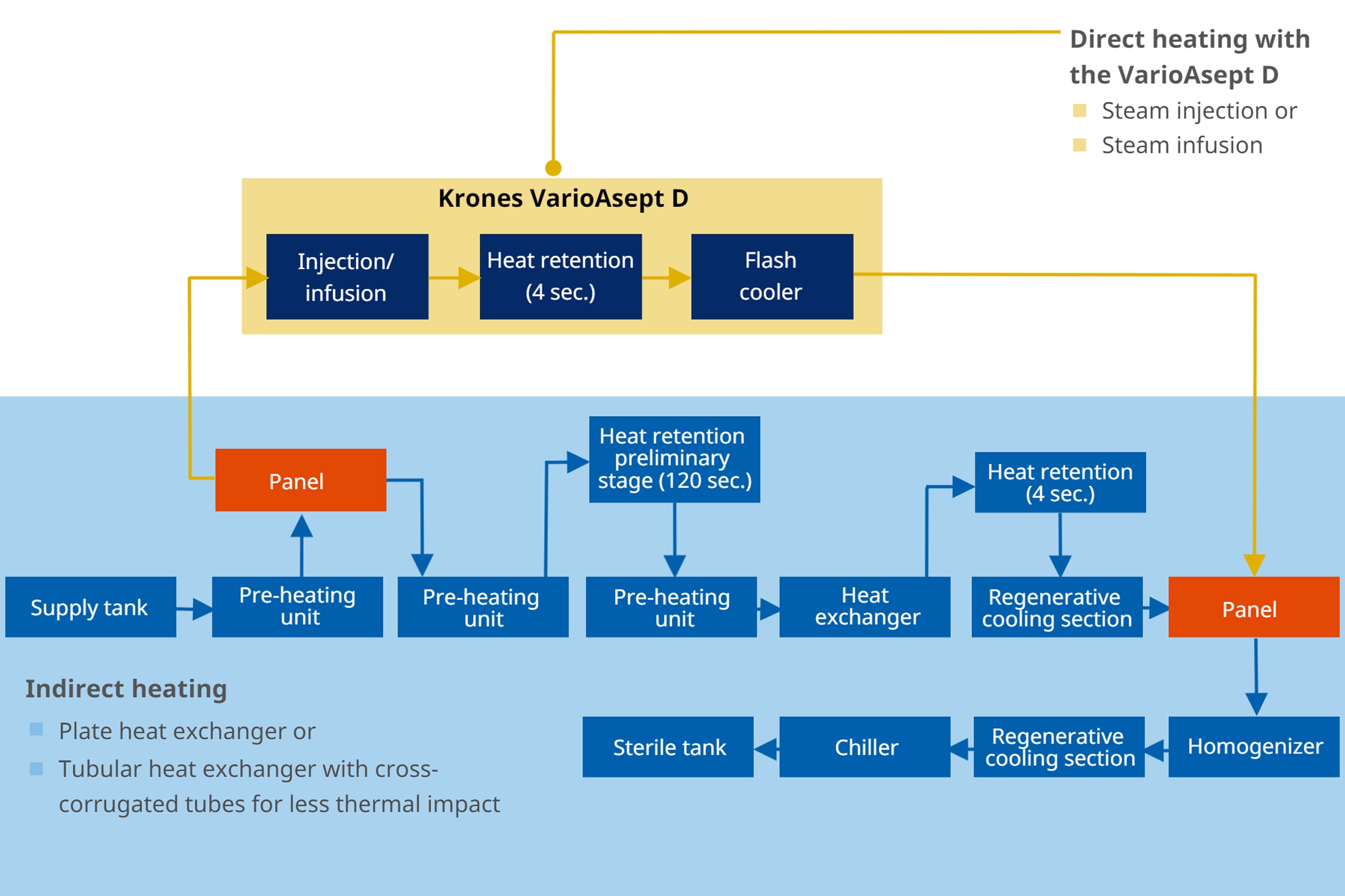

For extending product shelf-life, conventional UHT systems like the VarioAsept include a built-in plate or shell-and-tube heat exchanger which works on the principle of indirect heating. In a shell-and-tube heat exchanger, for example, cold product flows through an inner tube that is surrounded by a jacket pipe, through which hot water flows in the opposite direction in order to heat the product up to the desired temperature.

Lower investment costs and higher energy recovery are two reasons why indirect heat exchangers are a popular option. “But this technology does in fact have its weak points, particularly in regard to thermal impact: In the UHT process, the product is heated up to maximum temperature for ‘only’ a few seconds, that’s true, but the individual pre-warming steps, plus heat-holding – for 120 seconds at 90 degrees Celsius for protein denaturation, in order to increase continuous production time – and subsequent cooldown to filling temperature all add up to several minutes,” explains Stefan Höller, head of Product Management Processing Unit at Krones. “Especially at temperatures of over 60 degrees Celsius, however, chemical processes are triggered that adversely affect the product’s taste. So it’s vital to keep this timespan to a minimum.”

But not every product shows the same sensitive response to thermal treatment. Milk, in particular, has to be handled to maximised standards of carefulness and gentleness. The motto here is “the faster, the better” in order to minimise thermal stress. High temperatures and extended treatment times likewise increase deposit formation (also known as fouling) and lead to a reduction in continuous production time. In other words: They impair efficient production because the heating systems must be cleaned at regular intervals.