Fact check No. 3: The complicated matter of bio-plastics

Even if the name suggests otherwise: the ecological balance of bio-plastic is not necessarily better than that of conventional plastic materials.

Even if the name suggests otherwise: the ecological balance of bio-plastic is not necessarily better than that of conventional plastic materials.

The designation "bio-plastic" is not protected, and is therefore used for an extremely varied range of products. Most of them can be classified in one of two groups: in biodegradable and in bio-based plastics.

Biodegradable plastics decompose under certain environmental conditions to water and CO2. But to produce beverage bottles, a material is required that remains durable – especially under damp conditions. This is one of the reasons why biodegradable plastics cannot be the sole solution for the worldwide waste problem. On the contrary: the EU points out in its strategy paper on the recycling economy that the designation “compostable” could even induce consumers to throw away packages carelessly – and make the environmental situation even worse.

According to the German Federal Environmental Agency, even recycling in industrial composting plants is not the most sustainable way to dispose of plastics. As bio-plastics mainly decompose to water and CO2, they do not contribute to the formation of humus or fertiliser. The Research Services of the German Bundestag therefore find it ecologically more sensible to either use them for material recycling or at least to incinerate them for energy generation. However, in both cases conventional plastics prove to be considerably more efficient.

Bio-based plastics are not manufactured from crude oil, but instead from renewable resources. When considered individually, that is a sustainable approach. However, when the entire life cycle is considered, then bio-based plastics often have no ecological advantages, in the judgement of the Research Services of the German Bundestag. The reason: they are often produced from food crops cultivated especially for this purpose, such as maize, potatoes or sugar cane. In addition, the cultivation is usually not organic, but instead carried out with energy-intensive methods and using polluting pesticides and fertilisers. The ecological balance is a little better for those bio-plastics produced from agricultural or forestry waste. But even these are – at least for the time being – not more sustainable than conventional plastics that are produced with energy-saving technologies and are held in a material cycle.

Bio-plastics are not per se sustainable – for two reasons:

The greatest difficulty here: to get a handle on the global waste and resources problem, a material is required that

However, none of the bio-plastics available today could completely fulfil all three requirements for beverage packages. Of course, research on this subject continues and may still reveal the ideal material. But there's no reason to just stand by waiting for that to happen. For existing materials like PET can already be produced in a resource-economical process and kept in a closed circuit today. The technologies and the know-how for a sustainable use of plastics are already there – we just have to introduce them into the world more and use them consistently.

Why don't we just do away with plastics?

In view of the worldwide waste catastrophe, the desire for a plastic-free life is understandable – at least emotionally. However, from a rational standpoint, this will not do justice to either the plastics or the actual world we live in. For two reasons: plastics

However, this does not mean that the way in which we handle plastics today is always practical and correct. For even if in many application cases it is not possible to dispense with plastic: there are plenty of possibilities for employing it more efficiently, for using it more sustainably and for producing and processing it more resource-economically.

Companies from the beverage and food industry find a whole range of solutions at Krones for both reducing their material consumption for packages and for generally designing the life-cycle of plastic products to be more sustainable. From a material-saving packaging design to low-energy container production and the recycling of used plastic materials: we give PET bottles and other packages the opportunity for a sustainable, eco-compatible life – and that not only once, but again and again.

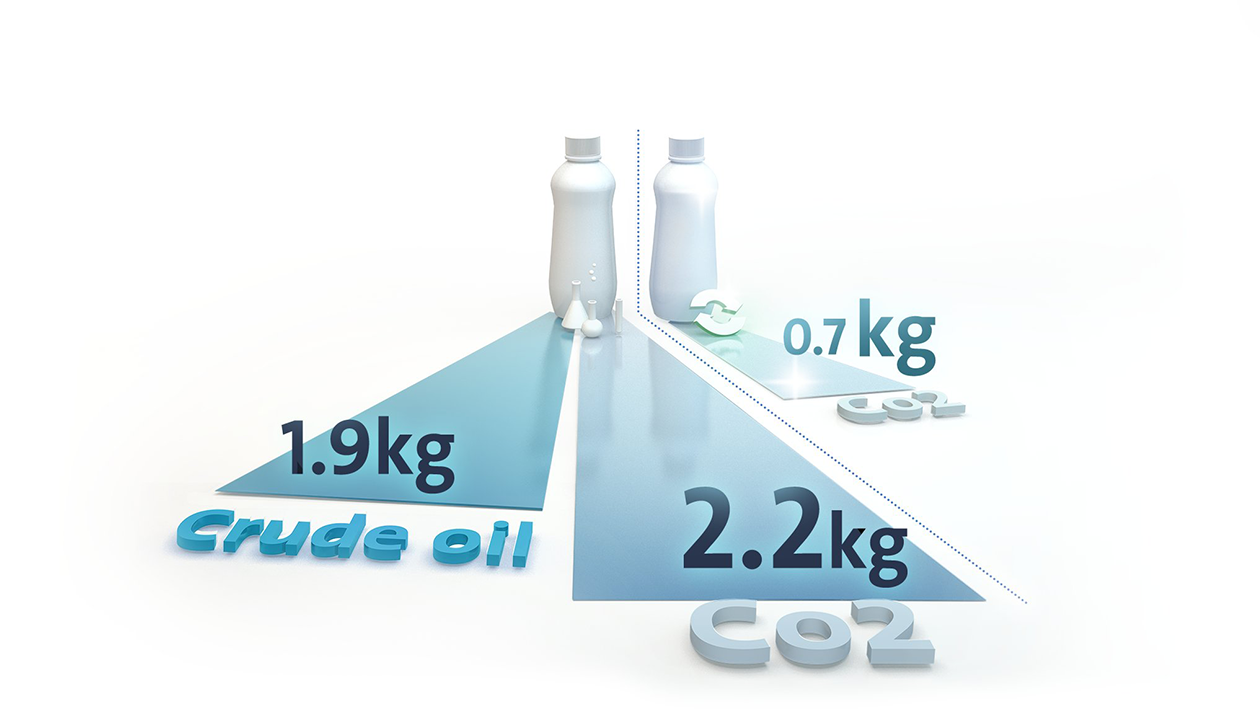

Compared to the same quantity of new product, during its production 1 kg of recycled PET (rPET) saves: