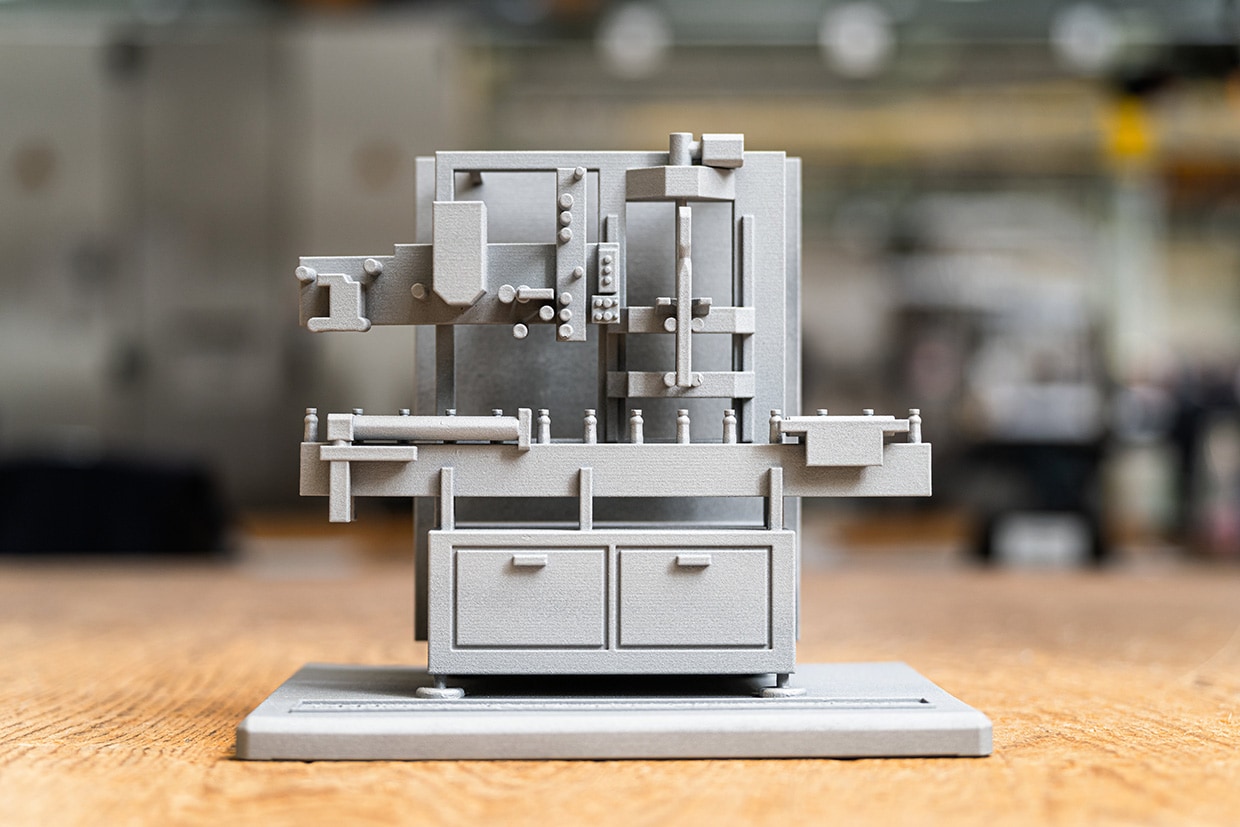

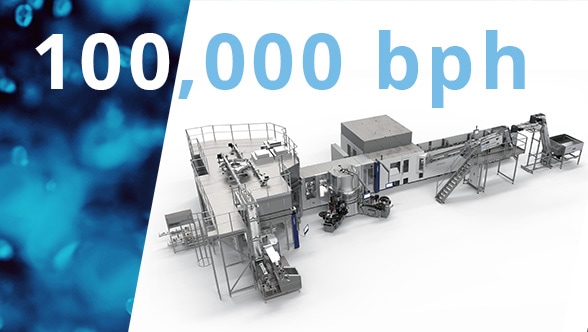

Seeing your new machines in person for the first time is always a very special experience. And that was certainly the case for Marco Balbiano, plant manager and chief information officer for Acqua Sant’Anna, on a recent visit to Krones’ factory in Neutraubling. Even though the process has become somewhat routine over the years – after all, he has overseen the installation of nine PET lines with Krones – this visit brought two premieres: The most lines currently running at Acqua Sant’Anna are of the Ergo Bloc L variety, while the newest addition that Krones is currently building for the Italian beverage maker is an aseptic one, the company’s first.

Acqua Sant’Anna