High flexibility for cold glue labelling

When it comes to decorating containers with cold glue and cut paper labels, the Ergomatic system has been setting the benchmark for many years now. The machine has been designed as rotary machine and is equipped with a precisely operating labelling station. In terms of efficiency, accuracy and speed, the Ergomatic is absolutely unrivalled.

At a glance

- Cold glue labelling on round and specially shaped containers

- Precise container positioning with centring bells and centring plates

- Quick access to the user interface through individual transponders

- Remote maintenance is available as an option

Method of operation

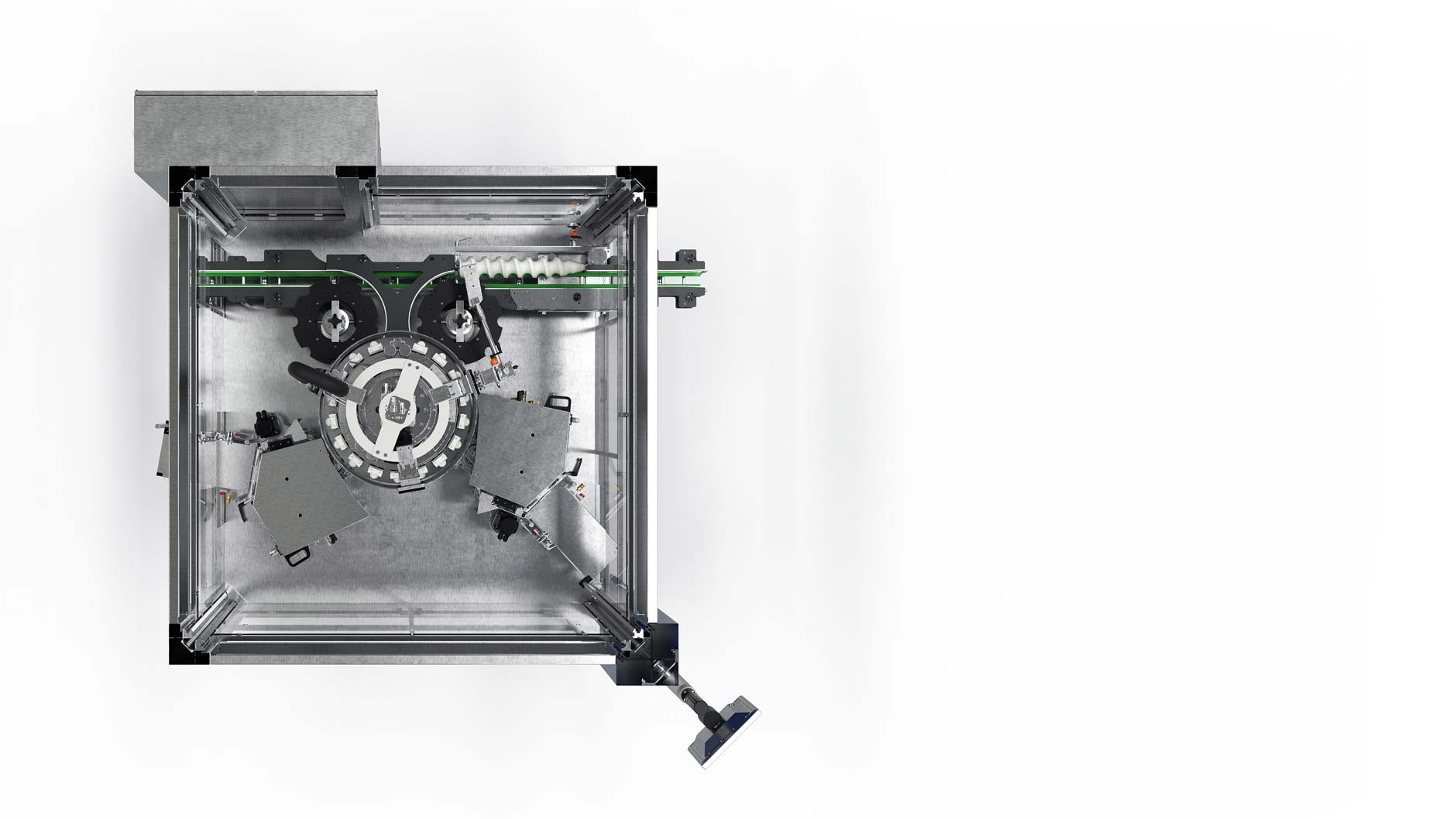

The labelled containers are collected by the discharge starwheel and transferred to the conveyor.

Brushes or roll-on sponges fix and smooth the labels on the container.

The glued pallets pick up the labels from the label magazine and pass them on to the gripper cylinder. The gripper cylinder positions these labels accurately on the containers as they pass by on the container table.

In each labelling station, a glue roller made of hardened steel applies a very thin layer of glue to the rubberised glue pallets.

The infeed starwheel transfers the containers to the revolving container table. Here they are firmly held between the container plates and the centring bells and centred for the labelling process.

An infeed worm spaces the incoming containers to the correct machine pitch.

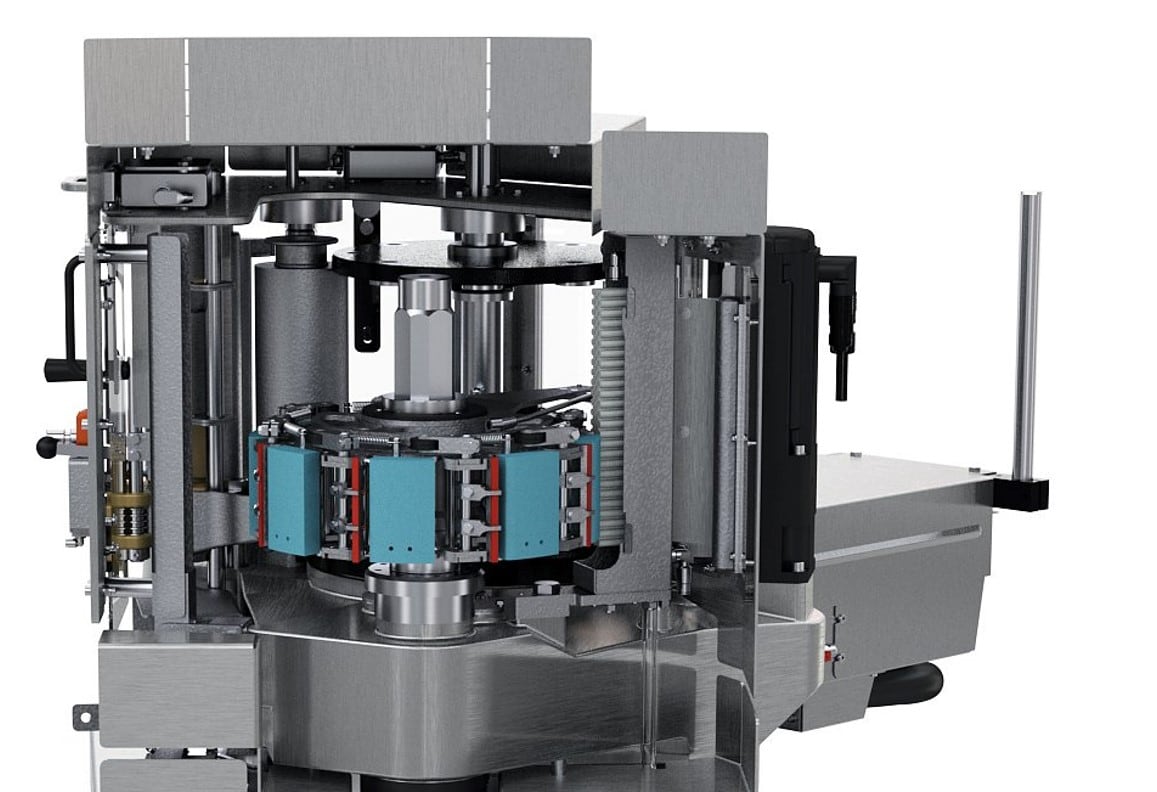

Ergomatic CL labelling station

Technical features and benefits

- Output ranges from 3,000 to 72,000 containers per hour with just one labelling station (depending on the label width)

- The glue pallets have an oscillating movement

- Low strain on the label through reduced pallet speed during label handling

- Hygienic design with smooth surfaces

- Quick and easy to clean

- Polygon holders for glue roller, pallets and gripper cylinders

- High-precision container decoration

- Glue roller bearing with freewheel device

- Reduced wear on the glue pallets

- Even glue application on the pallets

- The glue roller can be removed for cleaning without tools

- Mechanical adjustments with counter

- Exactly reproducible settings for type change-over

Benefits to you

User friendliness

The Ergomatic offers easy access and is very user-friendly to operate.

Flexible application

The Ergomatic can process a wide range of different labels.

Large output range

The machine covers the entire spectrum from the low to the maximum output range.

High labelling precision

Fixation of containers between the centring bell and the container plate ensures a highly precise container decoration.

Reduced workload for operators

The optionally available automatic magazine loading system reduces the workload for operators during production.

Time savings

Only short change-over times needed when changing container or label type.

Future-proof

It will still be possible to update and convert the Ergomatic system after many years of service.