Cap feed systems

Keeping the journey short – Your caps can experience the joy of movement

The basic spatial conditions, performance specifications and the required buffer characteristics are decisive when selecting the cap feed system. Only when the feed system precisely suits the filling concept is it possible to achieve high efficiency. Krones provides a wide range of variants which offer a suitable solution for all areas of use.

The variants at a glance

- Inclined sorters with inspection unit and buffer

- Sorting elevator with inspection unit and buffer positioned on the filler

- Sorting elevator with inspection unit and buffer close to the ground

- Double sorter with distribution gate

- Inclined sorter with inspection unit and cap buffer system ahead of cap sterilisation systems

- Sorting elevators with inspection unit and cap buffer system ahead of cap sterilisation systems

- Sorting elevators installed at low level with inspection unit and air conveyance of the caps to the capper

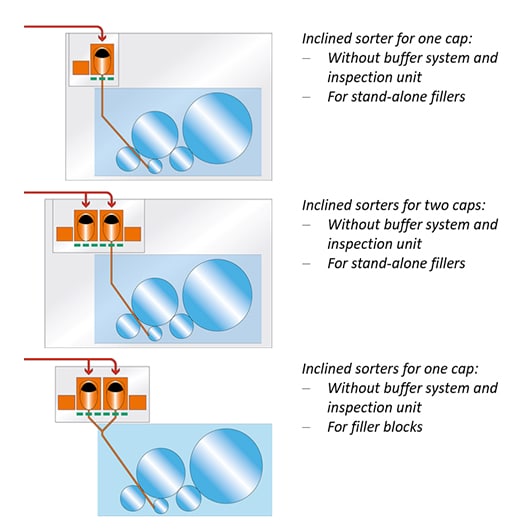

Inclined sorters

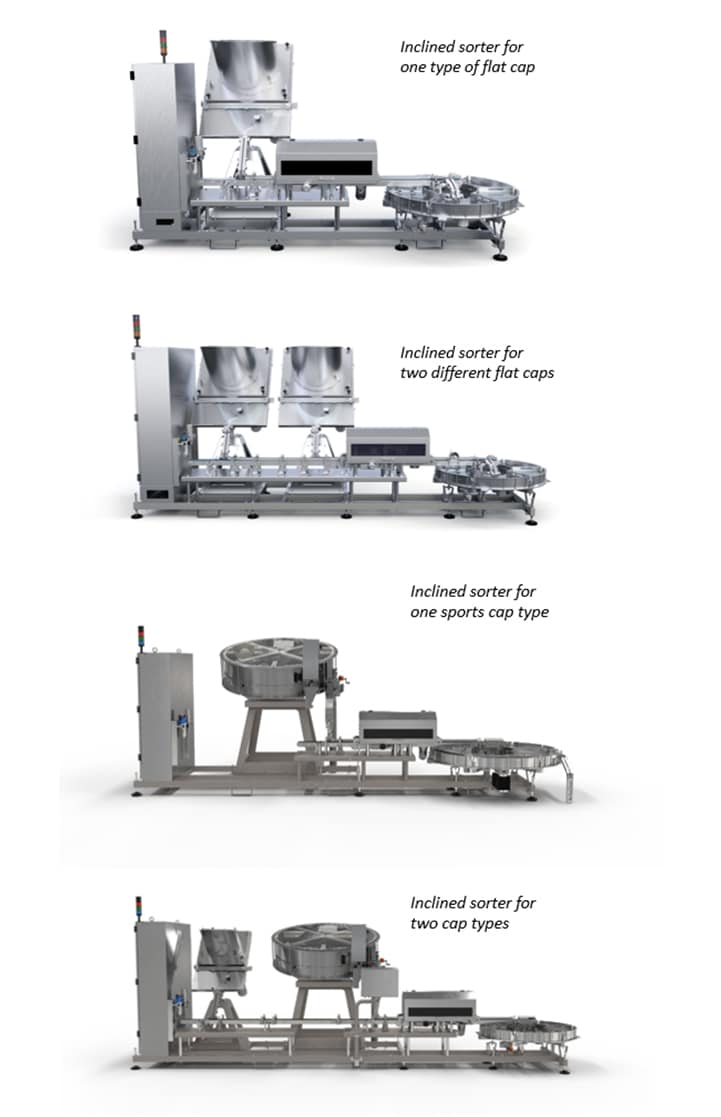

Mechanical inclined sorter for the orientation of rotationally symmetric flat caps (also as tethered caps):

- Controller integrated in the filler and terminal boxes on the sorters

- Design with distribution gate and Y-shaped channel as a redundant solution to ensure the continual operation of block synchronised systems (when handling one cap type)

Output

Up to 60,000 caps per hour depending on the cap type and dimensions.

Plus point

Proven system with one or two sorters for processing one or two cap types with different diameters.

Mechanical inclined sorter for aligning flat or sports caps (also as tethered caps) with cap inspection by a Checkmat CI-S* (sensor-controlled) as well as Checkmat CI-C* (camera-controlled) and an Accucap cap buffer system:

- After sorting: Examination of the caps for mechanical faults with the Checkmat CI-S inspection system and feeding to a rejection device

- Storage of the caps in the cap buffer system so that the block can be completely emptied in the case of a malfunction

- Installation on a clean room roof above the filler discharge or on a platform

Output

Up to 60,000 flat caps and 30,000 sports caps per hour, depending on the cap type and diameter (also tethered caps possible)

Plus points

- Proven system with one or two sorting units in order to process one or two cap types with different diameters and geometries

- High product quality as the caps are inspected in the cap inspection unit

- High flexibility thanks to minimal replacement of handling parts

Optional

Fully automatic cap changeover at the same colour via the UnitXpress

* CI-S = Cap Inspection – Sensor, CI-C = Cap Inspection – Camera

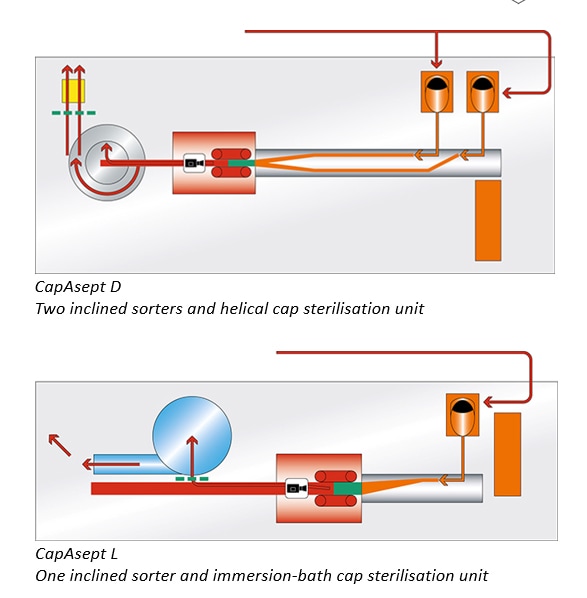

Cap feed unit with Checkmat CI-S (sensor controlled) or Checkmat CI-C (camera-controlled) inspection system, as well as a cap buffer system with one or two sorters:

- Installation of the system on the platform of an aseptic block system

- Storage of the caps in the cap buffer system so that the block can be completely emptied in the case of a malfunction

- Cap transfer to the aseptic helical cap sterilisation unit CapAsept D* or CapAsept L**

- The sterilised caps are buffered in the CapAsept L cap sterilisation unit during the sterilisation process

Output

Up to 81,000 flat caps per hour depending on the cap type and diameter (also tethered caps possible)

Plus points

- Inclusion of the inclined sorter in an aseptic system

- Buffering possible for dry cap disinfection

- No buffer required for wet disinfection as the peracetic acid immersion bath already acts as a cap buffer system.

* D = Dry (dry aseptic system) | ** L = Liquid (wet aseptic system)

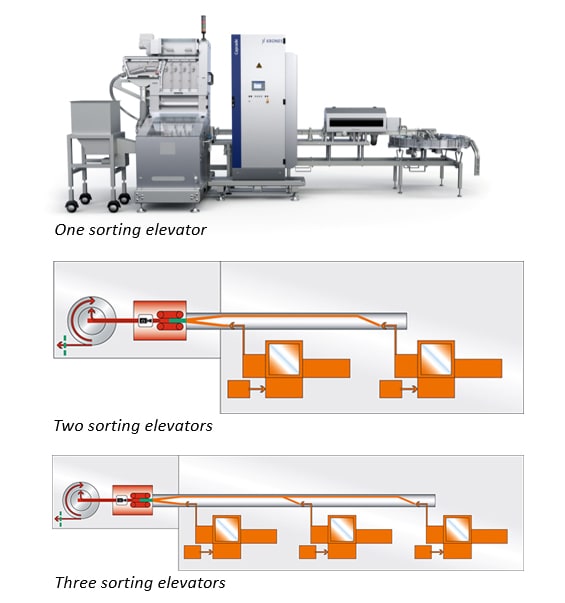

Capcade sorting elevator

The Capcade sorting elevator for the orientation of caps with cap inspection unit and Accucap cap buffer system:

- After sorting: Examination of the caps for mechanical faults with the Checkmat CI-S (sensor controlled) or Checkmat CI-C (camera controlled) inspection system and feed to a rejection device

- Storage of the caps in the cap buffer system so that the block can be completely emptied in the case of a malfunction

- The buffer capacity depends on the cap diameter

- Installation of the system on a clean room roof above the filler discharge or on a separate platform

Output

Up to 100,000 caps per hour depending on the cap type and diameter (also tethered caps possible)

Plus points

- Efficient system for cap sorting in the high-speed sector with up to three sorting elevators

- Perfect inspection of the cap quality and optimum system buffer characteristics

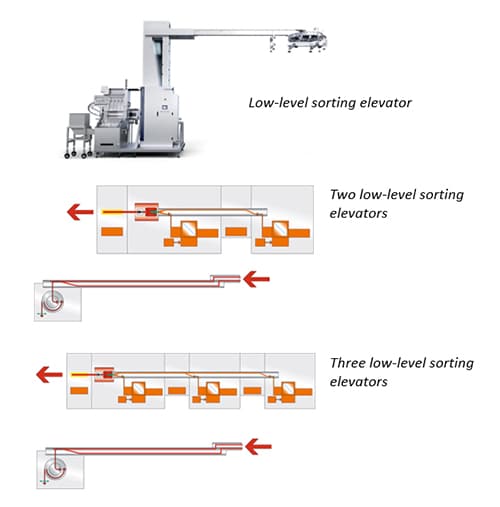

The Capcade sorting elevator for the orientation of caps with cap inspection unit and a cap buffer system:

- Low-level positioning of the Capcade sorter and inspection unit next to the filler, and arrangement of the cap buffer system on the machine clean room roof

- After sorting: Examination of the caps for mechanical faults with the Checkmat CI-S inspection system (sensor-controlled) and feeding to a rejection device when necessary

- Transfer of the intact caps to the Capvey Lift elevator system to supply the cap buffer system

- Storage of the caps in the cap buffer system so that the block can be completely emptied if a malfunction occurs

Output

Up to 100,000 flat caps per hour depending on the cap type and diameter (also tethered caps possible)

Plus points

- High user friendliness thanks to low-level sorting and inspection

- Efficient system for cap sorting in the high-speed sector with up to three sorting elevators

- Gentle handling of caps using Krones sorting elevator technology, gentle elevation thanks to the Krones Capvey lift

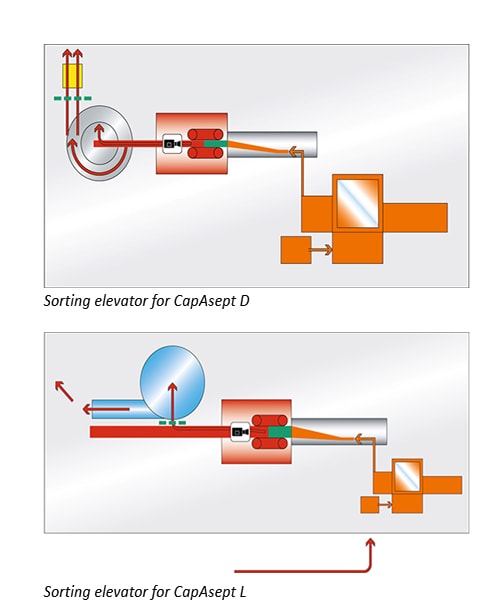

Capcade sorting elevator for the orientation of caps with cap inspection using a Checkmat CI-S (sensor controlled) or Checkmat CI-C (camera controlled) and Accucap cap buffer:

- Installation of the system on the platform of an aseptic block system

- Storage of the caps in the cap buffer system so that the block can be completely emptied in the case of a malfunction

- Cap transfer to the aseptic cap sterilisation unit CapAsept D* or CapAsept L**

Output

Up to 84,000 flat caps per hour depending on the cap type and diameter (also tethered caps possible)

Plus point

The systematic inclusion of the sorting elevator solution in an aseptic system. A cap sterilisation system (either wet or dry design) is integrated depending on the defined sterilisation concept.

* D = Dry (dry aseptic system) | ** L = Liquid (wet aseptic system)

Benefits to you

High processing reliability

A high product quality is guaranteed in those variants which include an integrated inspection system. Each cap is checked before it is transferred to the capper.

Extremely diverse variants

The cap feed system can be designed for conventional filling systems or aseptic filling systems, depending on the requirements. The inclusion of a second sorter allows the system to be quickly changed over to handle a different cap format.

Highest product quality

Depending on the system, the cap integrity can be checked with a separate cap inspection unit.

Economic efficiency included

The integration of a cap buffer system allows for the targeted emptying of the block.

Intelligent logistics

The systems are located next to the filler, either close to the ground or on the machine roof. This keeps the distances to be covered by your caps and the required conveyor sections short.

Well designed system layout

The cap feed systems are easily accessible for the user and maintenance personnel. Caps can be easily refilled. With numerous layout options, the selected feed system can be specifically tuned to suit the production requirements.