Loading and unloading pallets

Palletising robots for any application

The robots from the Modulpal Pro series provide wealth of options for loading and unloading pallets. You can individually combine each of the modules to suit your requirements. For example, you can create palletising specialists which are extremely quick and gentle on the product or highly flexible or also specialists which meet all these properties at the same time.

At a glance

- Applications:

- Palletisation and depalletisation of returnable crates

- Palletisation of cartons, packs with film and multipacks

- Maximum output: 650 layers per hour

- Maximum layer dimensions: 1,300 x 1,300 millimetres

- Maximum layer weight: 300 kg

- enviro-certified for reduced energy and media consumption

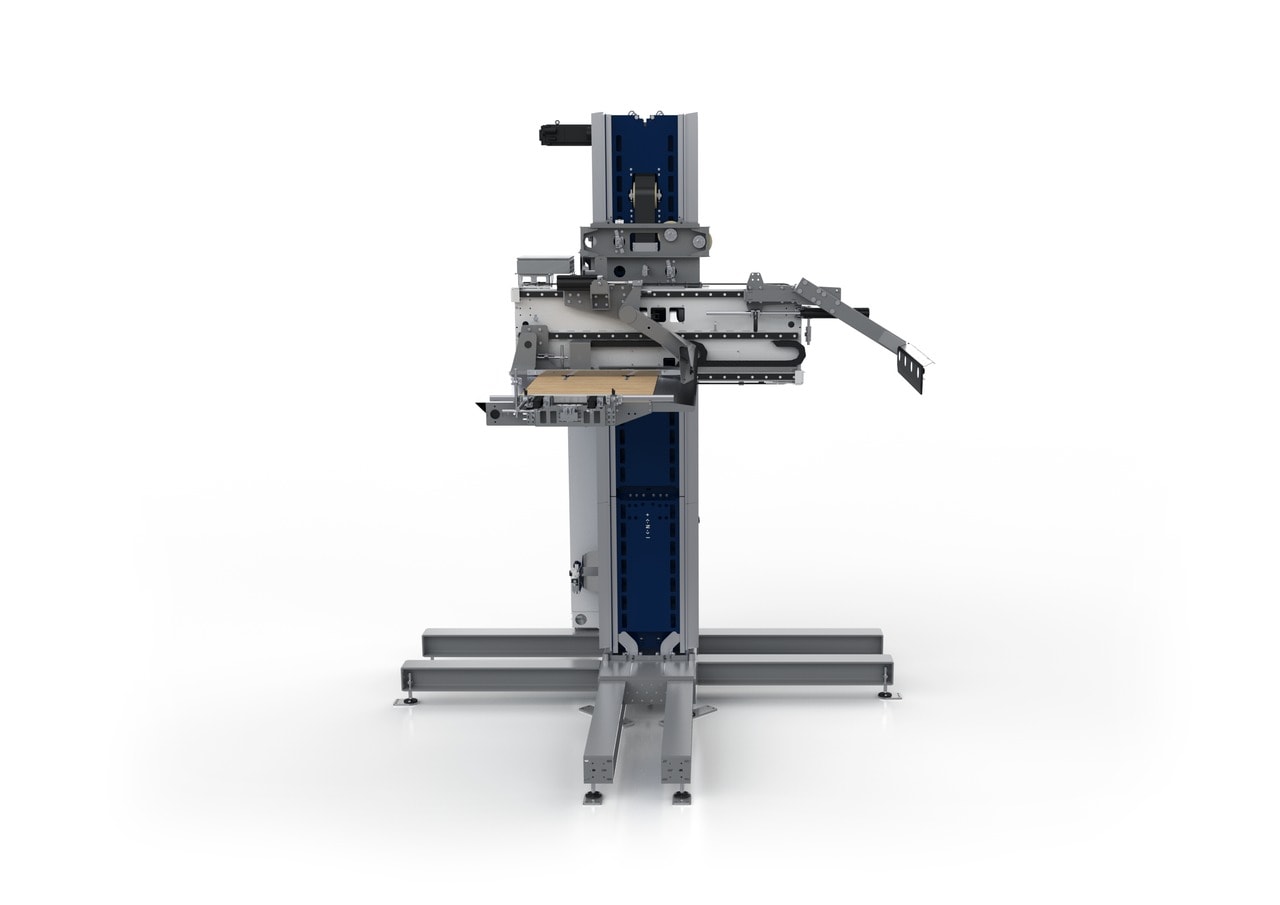

1A = 1 axis

With this system version, the packs are moved vertically. The pre-grouped packs are fed to the palletiser at a high infeed level and guided from four sides until they are positioned on the pallet. The open-top design of the loading station with shutter allows for the optimal insertion of the layer pads.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 460 layers per hour

1A = 1 axis

With this system version, the packs are moved vertically. The pre-grouped packs are fed to the palletiser at a high infeed level and guided from four sides until they are positioned on the pallet. The open-top design of the loading station with shutter allows for the optimal insertion of the layer pads.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 460 layers per hour

2A = 2 axes

C = Compact

A layer pusher moves the pre-grouped packs onto the transfer plate. The palletiser is then moved along two axes and sets the layer down on the pallet.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 340 layers per hour

2A = 2 axes

C = Compact

A layer pusher moves the pre-grouped packs onto the transfer plate. The palletiser is then moved along two axes and sets the layer down on the pallet.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 340 layers per hour

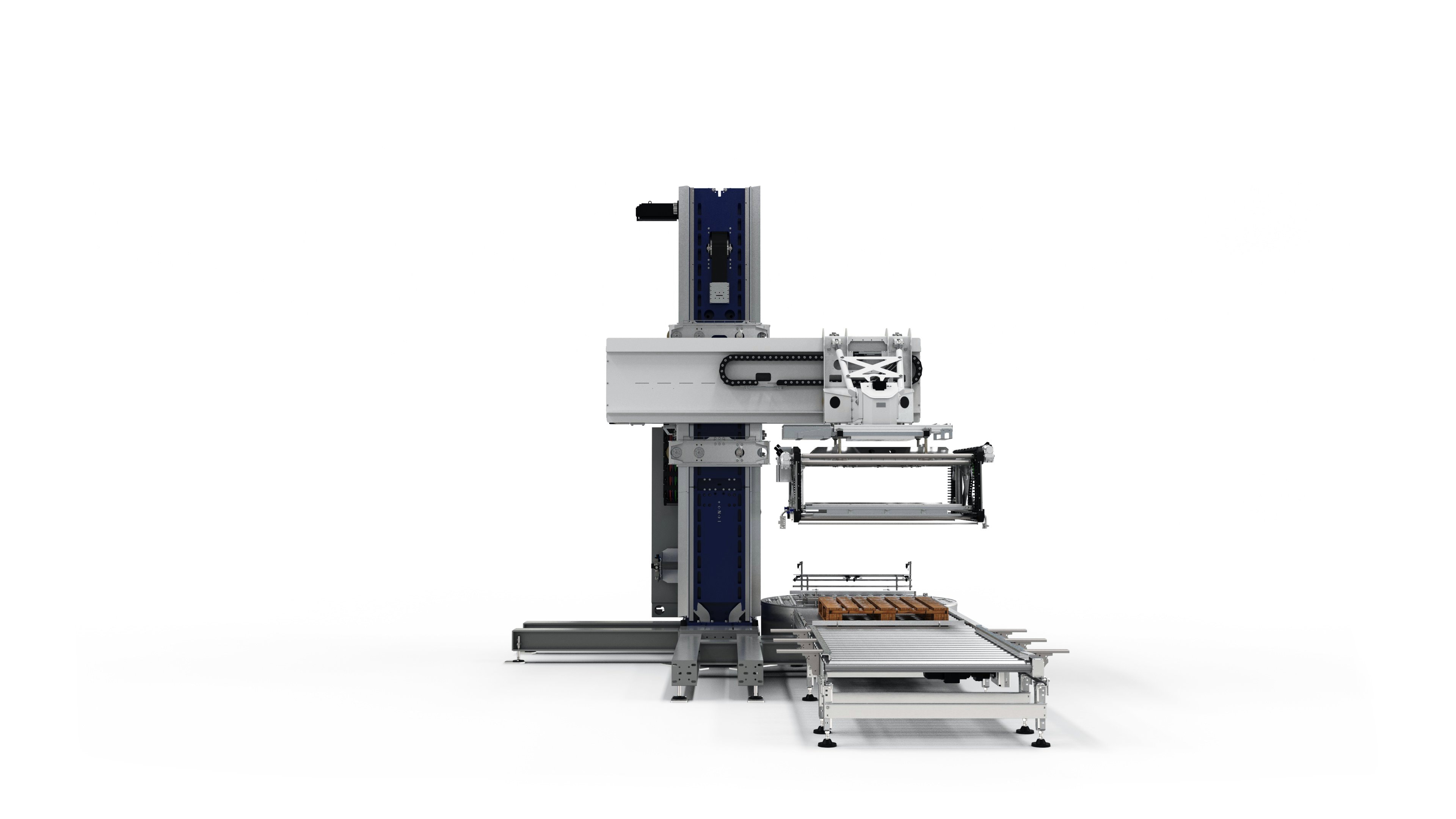

2A = 2 axes

This version, which moves along two axes, picks up the packs at the grouping station and places them down again on the pallet position. Depending on the gripper system, this variant is suitable for palletising non-returnable and returnable packs, and depalletising returnable packs. A rotating gripper head axis is optionally available.

Load-capacity: 700 kg incl. gripper system

Output (without layer pad handling):

Non-returnable packs: up to 360 layers/h

Returnable packs: up to 500 layers/h depending on the gripper system

2A = 2 axes

This version, which moves along two axes, picks up the packs at the grouping station and places them down again on the pallet position. Depending on the gripper system, this variant is suitable for palletising non-returnable and returnable packs, and depalletising returnable packs. A rotating gripper head axis is optionally available.

Load-capacity: 700 kg incl. gripper system

Output (without layer pad handling):

Non-returnable packs: up to 360 layers/h

Returnable packs: up to 500 layers/h depending on the gripper system

3A = 3 axes

The model 3A can master flexible tasks, both during palletising and depalletising. In addition to the linear lifting axis and a pivoting unit, this Modulpal Pro is also equipped with a rotating gripper head axis.

Load capacity: 700 kg incl. gripper system

Output (without layer pad handling):

Non-returnable packs: up to 360 layers/h

Returnable packs: up to 500 layers/h depending on the gripper system

3A = 3 axes

The model 3A can master flexible tasks, both during palletising and depalletising. In addition to the linear lifting axis and a pivoting unit, this Modulpal Pro is also equipped with a rotating gripper head axis.

Load capacity: 700 kg incl. gripper system

Output (without layer pad handling):

Non-returnable packs: up to 360 layers/h

Returnable packs: up to 500 layers/h depending on the gripper system

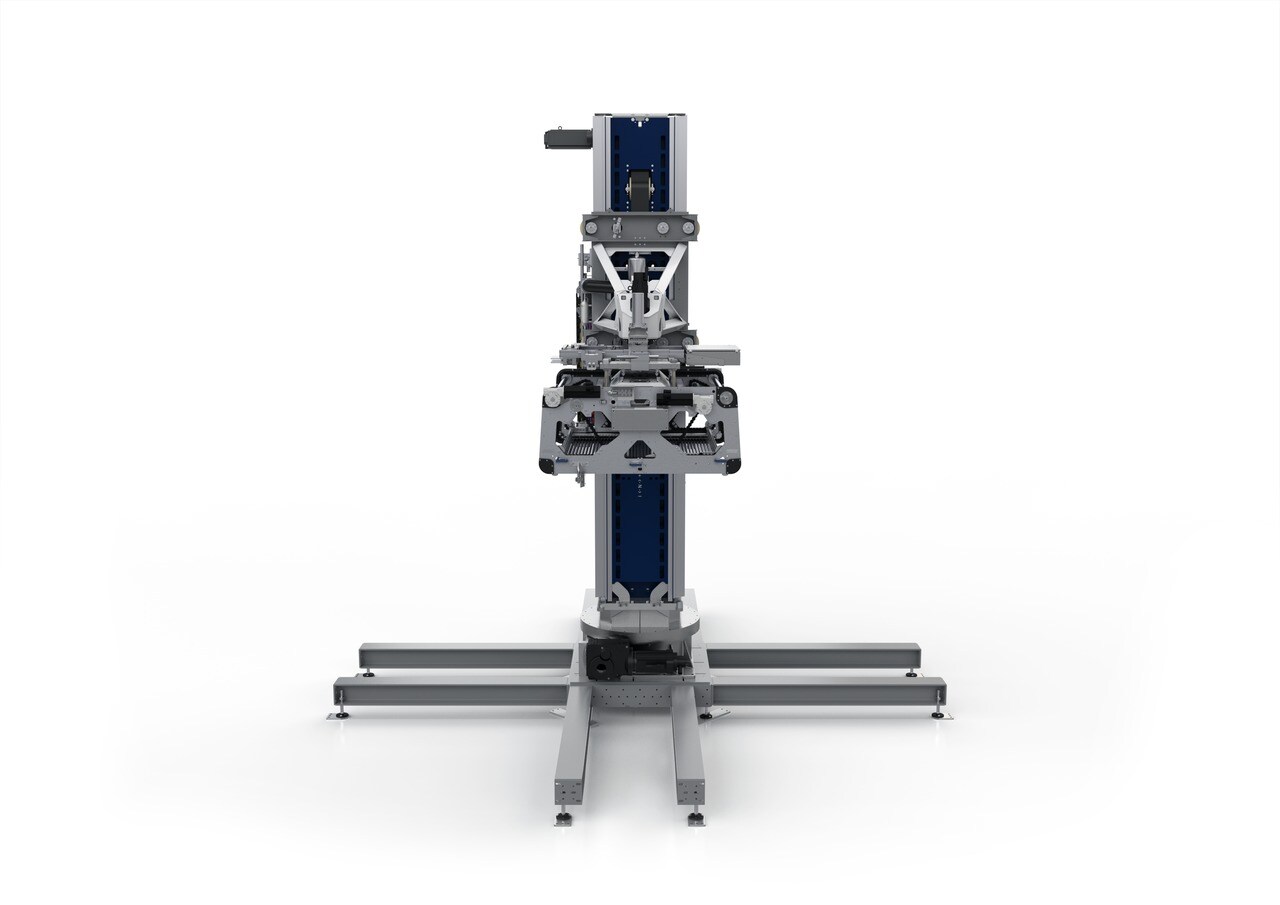

3AR = 3 axes

rotating

The base pivoting unit allows the robot to rotate around its own axis. This makes it possible for this Modulpal Pro to cover a working range of up to 360° when palletising and depalletising.

Note: Only for earthquake category 0.

Load capacity: 700 kg incl. gripper system

Output (without layer pad handling):

Non-returnable packs: Up to 360 layers per hour

Returnable packs: Up to 500 layers per hour depending on the gripper system

3AR = 3 axes

rotating

The base pivoting unit allows the robot to rotate around its own axis. This makes it possible for this Modulpal Pro to cover a working range of up to 360° when palletising and depalletising.

Note: Only for earthquake category 0.

Load capacity: 700 kg incl. gripper system

Output (without layer pad handling):

Non-returnable packs: Up to 360 layers per hour

Returnable packs: Up to 500 layers per hour depending on the gripper system

2A = 2 axes

P = performance

This version, which moves along two axes, picks up the packs at the grouping station and places them down again on the pallet position. Optimisations in the axis area and in layer handling have made it possible to increase the output compared to the Modulpal Pro 2A. Optionally, packing materials can be processed as usual or now even with a layer pad separator. The palletiser can also be equipped with a motorised gripper head turning unit.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 450 layers per hour

2A = 2 axes

P = performance

This version, which moves along two axes, picks up the packs at the grouping station and places them down again on the pallet position. Optimisations in the axis area and in layer handling have made it possible to increase the output compared to the Modulpal Pro 2A. Optionally, packing materials can be processed as usual or now even with a layer pad separator. The palletiser can also be equipped with a motorised gripper head turning unit.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 450 layers per hour

3A = 3 axes

P = performance

The 3AP model is very flexible during loading. In addition to the linear lifting axis and a pivoting unit, this Modulpal Pro is also equipped with a rotating gripper head axis. Optimisations in the axis area and in layer handling have made it possible to increase the output compared to the Modulpal Pro 3A.

Optionally, packing materials can be processed as usual or now even with a layer pad separator.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 450 layers per hour

3A = 3 axes

P = performance

The 3AP model is very flexible during loading. In addition to the linear lifting axis and a pivoting unit, this Modulpal Pro is also equipped with a rotating gripper head axis. Optimisations in the axis area and in layer handling have made it possible to increase the output compared to the Modulpal Pro 3A.

Optionally, packing materials can be processed as usual or now even with a layer pad separator.

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: Up to 450 layers per hour

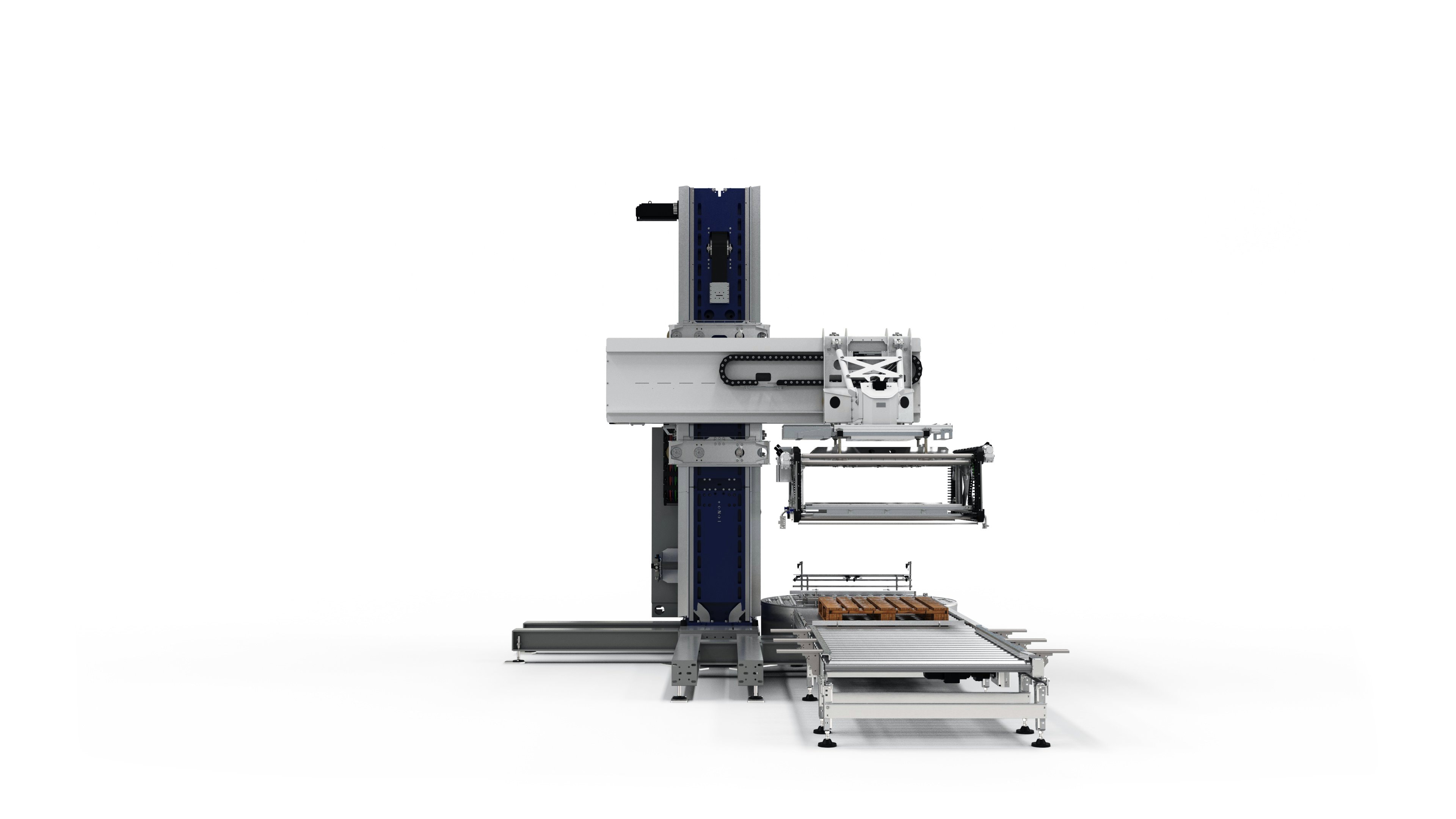

1A = 1 axis

D = double column

The Modulpal Pro 1AD consists of two synchronously operating modules: a transfer and a loading module.

The pre-grouped pack layer firstly enters the transfer module and is moved to the correct transfer height. The palletising module picks it up and positions it on the pallet. During this entire process, the layer is guided from four sides.

Special features of the Modulpal Pro 1AD:

- No pneumatic components required at all

- Mounted on a stable base frame for quick assembly and more independence from the floor quality

- For high outputs at low level pack infeed

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: up to 650 layers/h

1A = 1 axis

D = double column

The Modulpal Pro 1AD consists of two synchronously operating modules: a transfer and a loading module.

The pre-grouped pack layer firstly enters the transfer module and is moved to the correct transfer height. The palletising module picks it up and positions it on the pallet. During this entire process, the layer is guided from four sides.

Special features of the Modulpal Pro 1AD:

- No pneumatic components required at all

- Mounted on a stable base frame for quick assembly and more independence from the floor quality

- For high outputs at low level pack infeed

Load capacity: 300 kg (max. layer weight)

Output (without layer pad handling): Non-returnable packs: up to 650 layers/h

Grouping system for non-returnable packs

All Modulpal Pro versions can be combined with the following grouping systems:

- Creates different layer patterns for non-returnable packs

- Processes single-lane or double-lane packs

- Turns and distributes the packs exactly according to the specifications for the pre-programmed layer pattern

- Depending on the required output, one or two modules are employed for layer grouping

- Equipment with parallel kinematic robot (tripod)

Grouping with flush-grid belt infee

- Servomotor-driven flush-grid belt without spacing device

- Infeed conveyor in flush-grid belt design without spacing device

- Driven pre-grouping station with motorised centring on both sides

- Internal motor-driven turning unit

Grouping with a roller infeed

- Grouping station with infeed roller conveyor in single-lane or double-lane design for returnable packs

- Use of spacing devices possible

- Pre-grouping station with plastic flat-top or roller version

- Internal or external turning device

Benefits to you

Freedom of combination and high performance

Depending on the task, all components can be combined with each other flexibly. This results in an optimal machine configuration from low to high output ranges – even with a low pack infeed.

Quick start-up

Due to the set-up on a stable base frame, the palletiser can be installed very quickly. Therefore it also does not depend on the quality of the subsurface.

Maintenance-friendly and noise-protected

The integrated belt drive simplifies maintenance and reduces noise. The system was deliberately constructed with no lubrication systems so that the extent of maintenance could be kept low.

Flexibility and versatility

A large selection of gripper heads enables optimal processing of different pack types and sizes as well as different pallet dimensions.

Sustainability –reduced energy and media consumption

The use of servo motors and energy recovery systems, the extensive omission of compressed air consumers and the use of encapsulated, lifetime-lubricated bearings results in low energy and media consumption.

Economic efficiency

Thanks to the uniform modular component system, handling of several Modulpal Pro versions at a time is especially economical.

High dynamics and accuracy

The servo motor drive system for the shafts allows highly dynamic movements and maximum accuracy for repetition.

Ease of operation

Depending on the version, the system can change to other sizes semi-automatically or fully automatically. And if jobs arise which require operator intervention, situation-related indicators with graphical instructions allow the machine to be directed intuitively.

This is why the Modulpal Pro is enviro-classified

- Servo-driven main drive of the energy efficiency class IE4

- Energy recovery via the modular B&R ACOPOSmulti drive system

- Omission of pneumatic drives to a large extent

- Use of enclosed lifetime-lubricated bearings

- Employment of enviro-compliant H1 lubrication grease and oil

- enviro option: Energy measuring package