High flexibility with self-adhesive labelling

For processing self-adhesive reel-fed labels

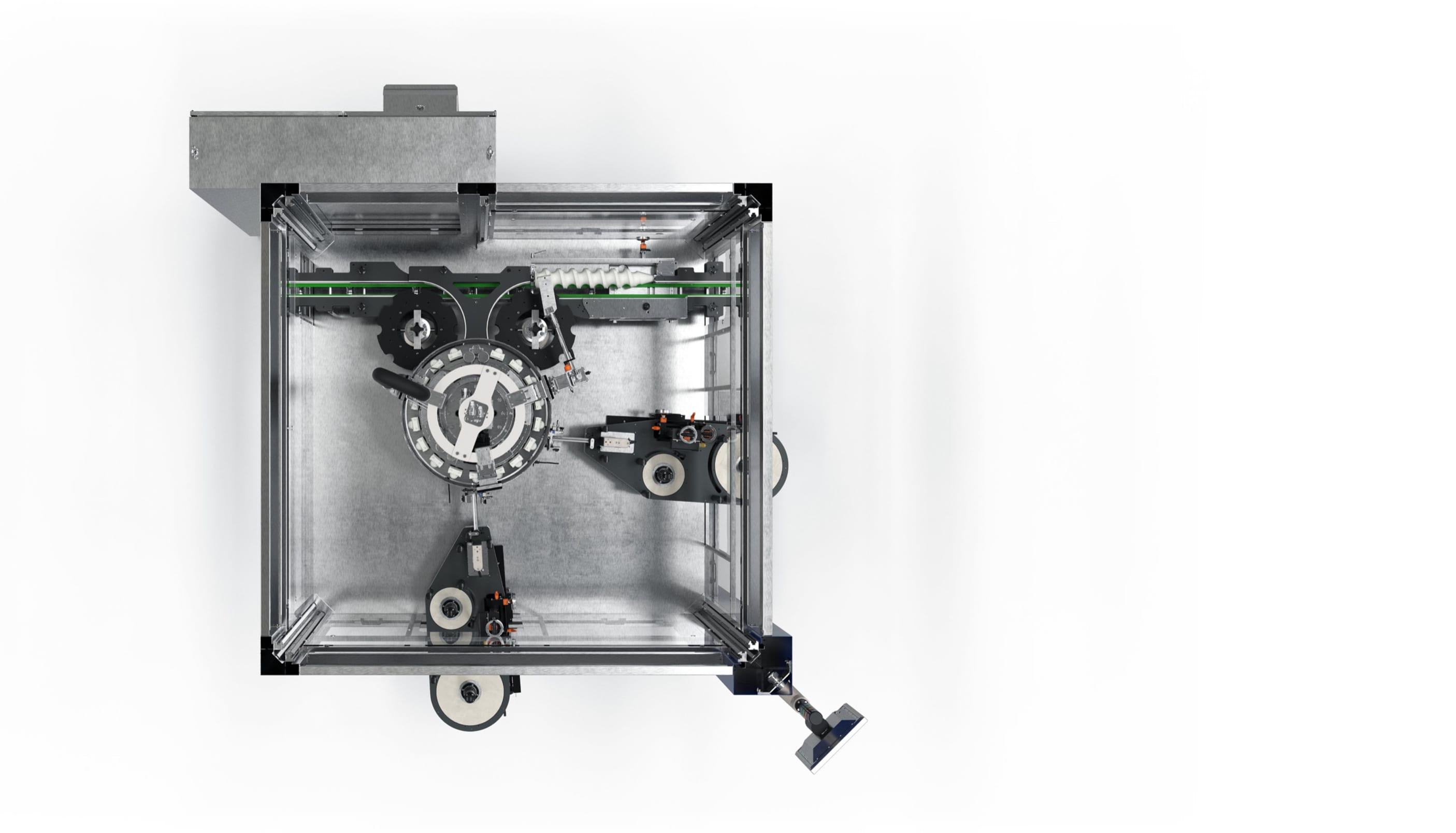

When it comes to decorating containers with self-adhesive reel-fed labels, the Autocol has been setting the benchmark for many years now. The machine has been designed as rotary machine and is equipped with a precisely operating label applicator. With regard to efficiency, accuracy and speed, the Autocol absolutely takes a leading position.

At a glance

- For processing self-adhesive reel-fed labels

- Decoration of cylindrical or specially shaped containers

- Precise container positioning using centring bells and container plates

- Operation by means of individual transponders for quick access to the user interface

- Use of remote maintenance possible as an option

Method of operation

The labelled containers are collected by the discharge starwheel and transferred to the conveyor.

Brushes or sponge rollers hold the labels on the container and smooth them down.

The label is detached from the label carrier film at the application wedge and precisely transferred to the container.

In the label applicator, the labels are unwound from the reel and conveyed by a servo motor to the application wedge.

The infeed starwheel transfers the containers to the rotating container table. Here they are firmly held and centred between the container plate and the centring bell.

An infeed worm spaces the incoming containers to the correct machine pitch.

Two variants for self-adhesive labelling

- Output range of 3,000 to 66,000 containers per hour, with only one label applicator, depending on the label width

- Feed and tension roller technology with contact-free label buffer system

- Maximum labelling precision possible for the thinnest of films

Autocol TS: the label applicator for the high output range

Technical features and benefits

- High machine availability

- The machine does not need to be stopped for cleaning

- Collecting and fixing the label reels without any tools

- User-friendly change of the label reels

- Ultrasonic sensor for the label position

- Precise positioning regardless of the label material

- Adjustment of the axes with a handwheel including register

- Quick and repeatable accurate change-over for each label dress

- Automatic splicing available as an option

- No machine stop at end-of-reel

- Feed and tension roller technology with contact-free label buffer system

- Maximum labelling precision possible for the thinnest of films

- Output range of 3,000 to 35,000 containers per hour, with only one label applicator, depending on the label width

- Hybrid roller technology for transporting the label film

- Flexible applications for thick, thin and multi-layered labels

Autocol CL: The versatile label applicator for the low and medium output range

Technical features and benefits

- High machine availability

- The machine does not need to be stopped for cleaning

- Self-explanatory structure

- User-friendly and easy to operate

- Collecting and fixing the label reels without any tools

- User-friendly change-over of the label reels

- Ultrasonic sensor for the label position

- Precise positioning regardless of the label material

- Adjustment of the axes with a handwheel including register

- Quick and repeatable accurate change-over for each label dress

- Hybrid roller technology for supplying the label film

- Flexible applications for thick, thin and multi-layered labels

Your benefits

High labelling precision

Fixation of the containers between the centring bell and the container plate ensures a highly precise container decoration.

Flexible application

The Autocol processes a broad range of different label sizes.

Broad output range

With its different designs, the machine covers the entire spectrum from the low to the maximum output range.

User friendliness

The Autocol features ease of access and ease of operation.

Time savings

Only short change-over times needed when changing container or label type.

Less work for the operators

Significant relief for the operator thanks to optional features such as the reel splicing unit or the AUTO-change mode.

Future-proof

The Autocol can be retrofitted and converted also after many years of operation.