But first, some more background information: The in-house bottle design team was set up in Dubai in 2019. The original intention was to cover countries in the Middle East and North Africa, with still water, soft drinks and juices being particularly prominent in these markets. However, the design team is now so successful that it is also active in other countries throughout the African continent. But how do you design a bottle in the first place? And why does the region play a role? That's where we finally come to our creative minds. So, let me introduce you: Seung and Giulio, who have enriched the bottle design team since the beginning and answered a few questions about themselves and their daily work.

During my work at Krones, time and time again, I'm surprised at how big the company is and how diverse the employees are at the same time. I always find it particularly interesting to learn about Krones' international subsidiaries beyond the Neutraubling site – and so I was naturally captivated recently when I heard about our in-house bottle design team at the Dubai site. Then I even had the chance to meet the two creative minds behind it (virtually) – and I want to introduce them to you here.

Could you maybe shortly introduce yourselves?

Seung: Hi, my name is Seung Hong, I’m an Industrial Designer and working for Krones in UAE as a bottle designer since April 2019.

Giulio: I’m a 27-year-old industrial designer from Italy. I’ve been involved with the beverage industry for a few years and I joined the Krones group one year and a half ago. I am now in the role of bottle designer for this region and I’m handling the retrofits for this region.

How does working in a team look like in your case?

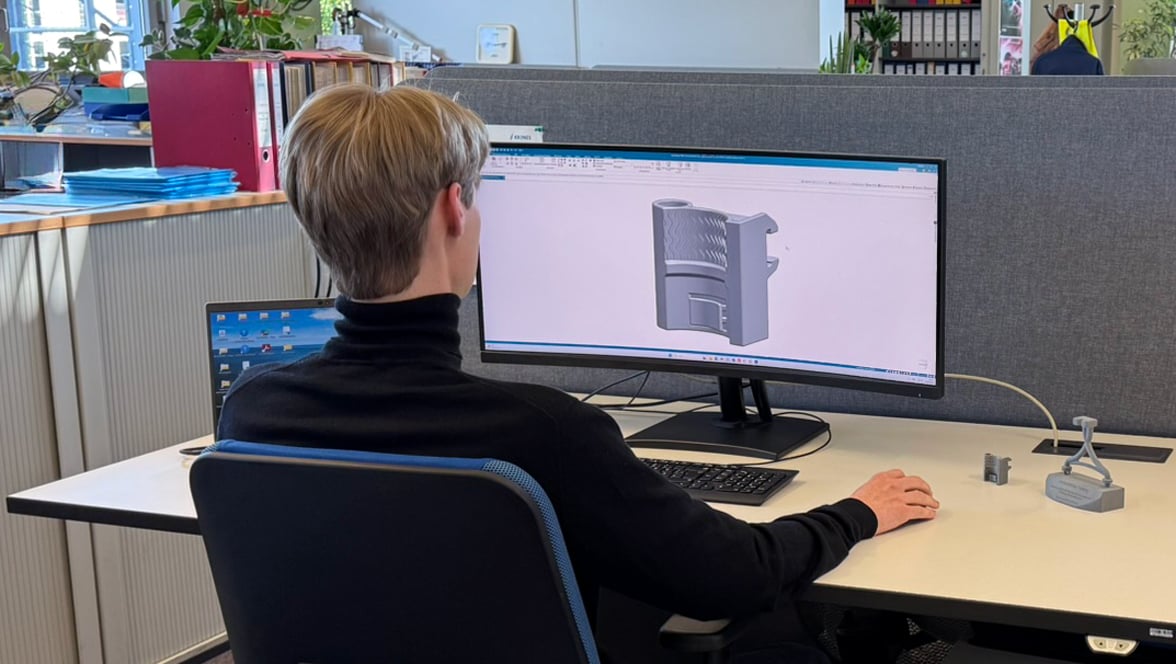

Giulio: Me and Seung have a lot of common background and we don’t need much to be in sync. We have compatible skills and we let each other play to our strengths. He is an outstanding concept designer, while I am more at ease modeling directly onto CAD. We can overlap, of course, but we found this workflow to be the most effective.

Seung: Yes, that’s true, we do have our specialty areas. Giulio has extended knowledge in bottle engineering and CAD development, and I have extended experience in consumer insight, concept development and the rapid prototyping area. But we mostly share the common area of bottle development process duty – which is working out very well.

Could you maybe tell us a little bit about the process of bottle designing?

Giulio: Bottle design is a complex topic for a variety of reasons. Firstly, because Krones doesn’t sell bottles, our customers do. So, when I design bottles I have to keep in mind the whishes, needs, and limitations not just of our customers, but of their customer as well. Additionally, this is a very specialized field and we can’t expect all the stakeholders to know all the details and requirements a bottle needs to run on a line; that’s what we bring on the table. I would describe this process – using a metaphor quite common in design – as having a chameleon view: one eye fixed on what’s mechanically and technologically feasible, and one fixed on the customer wishes.

What characterizes the region you’re working in and for from your point of view?

Giulio: Each market has its own peculiarities, and not just in term of macro regions. Sometimes you can isolate the market preferences up to a single country or even parts of it. Some are dictated by national laws, some are dictated by culture and sense of aesthetics. The overall impression we get from the market Middle East is that it is following the path of Europe with a few years of delay. The push for lightweighting that is dominating the European countries, also led by the legislation, is trickling down here as well. The conversion from 30 millimeter neck finish to 29 millimeter has been completed almost everywhere, but no one has ventured to 26 or 25 millimeter yet. I believe it’s a matter of time before this market will follow.

We recently got the addition of more African countries, too, and that market is – for the majority – one step behind the Middle East. We can see the transformation happening before our eyes but it’s slow and it will take time.

In my experience, there is also a noticeable difference in customer behavior between the two macro areas we are dealing with. In the Middle East they are more demanding and they expect to have every technical decision explained. In Africa they like to be involved in the creative part and they tend to trust our technical expertise. And I guess that these differences between the markets of the different regions show perfectly how much it is worth to live in the region or to be close to it, to develop a feeling for it and to have a regional focus.

Seung: As statistics show, 60 percent of consumers are impulse buyers. The average consumer spends 5-10 seconds to choose grocery items and then moves on to the next items in the supermarket. In our region, these consumer insights are applied to the beverage and drinking water market also. ’Be bold in design, stand out from the shelf!’ I believe this should be our design mission statement in the region.

How does your usual day of work look like?

Seung: It isn’t the same every day for sure, but I will explain all activities of the design process of our studio. Every day, a mix of these activities are our day to day tasks – so that will probably describe our daily life a bit:

-

Market research in the region (mood board and packaging trends)

-

Brainstorming session for concept development, 2D/sketches (including customer consultation)

-

bottle development in CAD

-

Rapid prototyping, 3D prints

-

Computer rendering

-

2D/3D drawing release

-

Preform evaluation etc.

Giulio: Yes, as Seung shows our team is involved from the initial bottle concept to the mould construction. We handle several projects at once, all at different stages of progress, so there’s not an “average day”. Our workflow starts with some concept designs, in the form of sketches or renderings, that the customers narrow down to one or two choices. The output is presented to them as bottle drawings and we can help the decision process by printing mockups in-house, so that the customers can rely on physical samples and not just on drawings. After we get the green light, we manufacture a pilot mould that we use to blow some samples and check the bottle quality and dimensions in the lab. We then discuss and explain the lab report to the customers, before proceeding to manufacture the serial molds.

In addition, we often act as consultants for customers, suggesting solutions that will help them get a performance increase or save money. We have the advantage of the vertical knowledge we acquired working in this field and we can tell when a modification will bear benefits.

That definitely sounds like an exciting and multifaceted everyday life and great teamwork to me. Thank you very much, Seung and Giulio, for taking the time and good luck on your further way. I'm already looking forward to your further designs!