On its way through the rinser, a bottle is normally led through the carousel with the help of clamping jaws. These are made of plastic and are very robust, wearing only slowly – which makes them really practical. Their use presents an obstacle, however, because they are configured for the respective bottle type or size. In the event of a change-over, therefore, the operator has to replace every clamp by hand. Not only does this require manual intervention, it also means every single clamp size has to be kept in stock. All in all, the traditional clamping jaws offer benefits, but unfortunately the process is costly and time-consuming. Little wonder, then, that the question was asked: Couldn’t we improve on this?

As befits the claim “Solutions beyond tomorrow”, the Krones team works constantly on innovation and refinements. And even those who have only been in the company a matter of months can contribute to that, as the prospective technical product designers have proved. The apprentices have now managed to take their 3D printing idea as far as a patent application.

Lots of creativity – one solution

“We certainly can,” answered the prospective technical product designers, who have been attending a 3D printing workshop every year since 2022. At one of them, they worked together with Krones’s internal 3D printing centre to solve the problem described above.

The task? “Design a clamping jaw that is suitable for 3D printing and overcomes the weaknesses of its conventionally milled counterpart.” The apprentices then set about developing solutions together with the 3D printing centre team. “There were three groups who looked at it. To find the best solution, we ended up combining all the ideas of the apprentices and developing the optimal component from there,” says Andreas Gebhardt, a trainer at Krones, who was involved in the process of designing the new clamping jaw.

Reinhard Ortner, who heads up the 3D printing centre, also praised the cooperation: “It was impressive to see the passion with which the apprentices worked at finding a solution to the task. And once we had the end result in front of us, we thought: ‘Do you know, that’s so good we should apply for a patent straight away.‘ This is something the apprentices can be very proud of, and not only that: Krones can also be proud of its apprentices.”

This is something the apprentices can be very proud of, and not only that: Krones can also be proud of its apprentices.

Reinhard OrtnerHead of the 3D printing centre at Krones

Reinhard OrtnerHead of the 3D printing centre at Krones

Brilliant in many ways

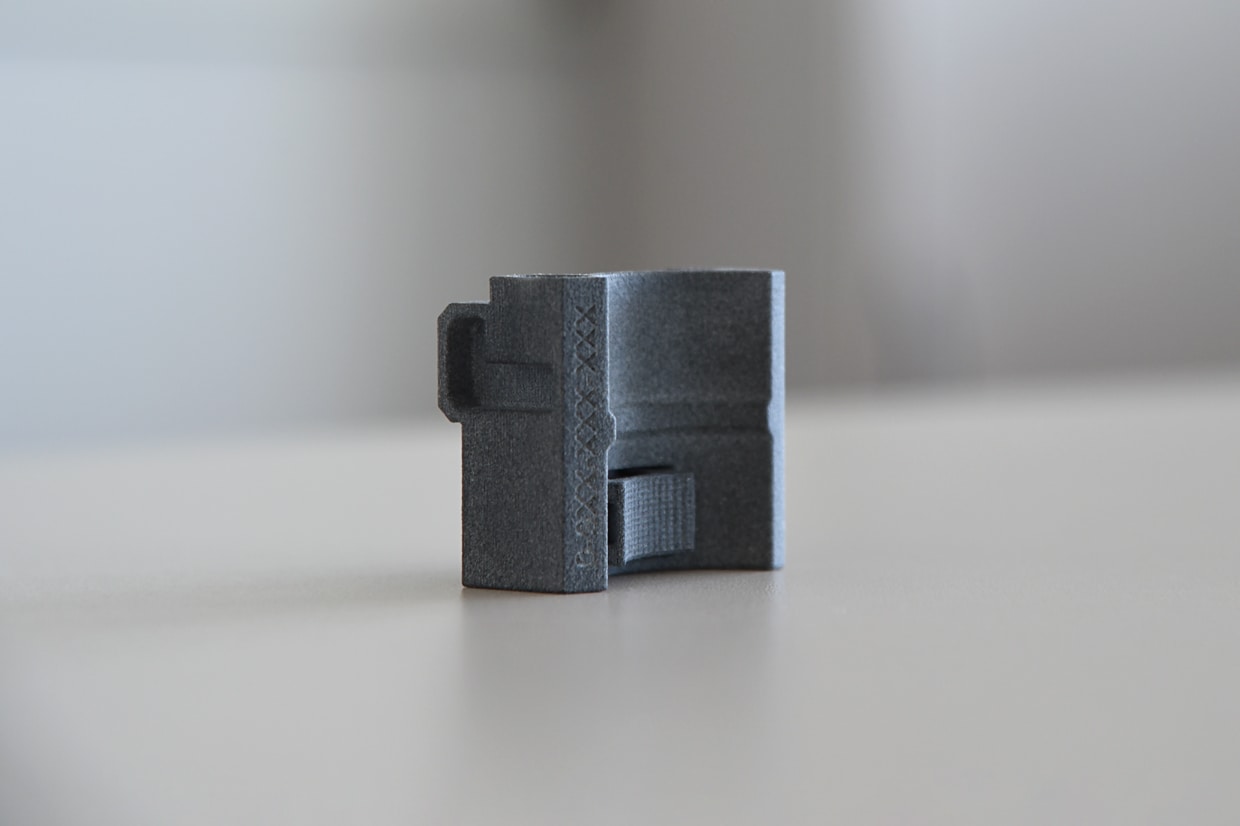

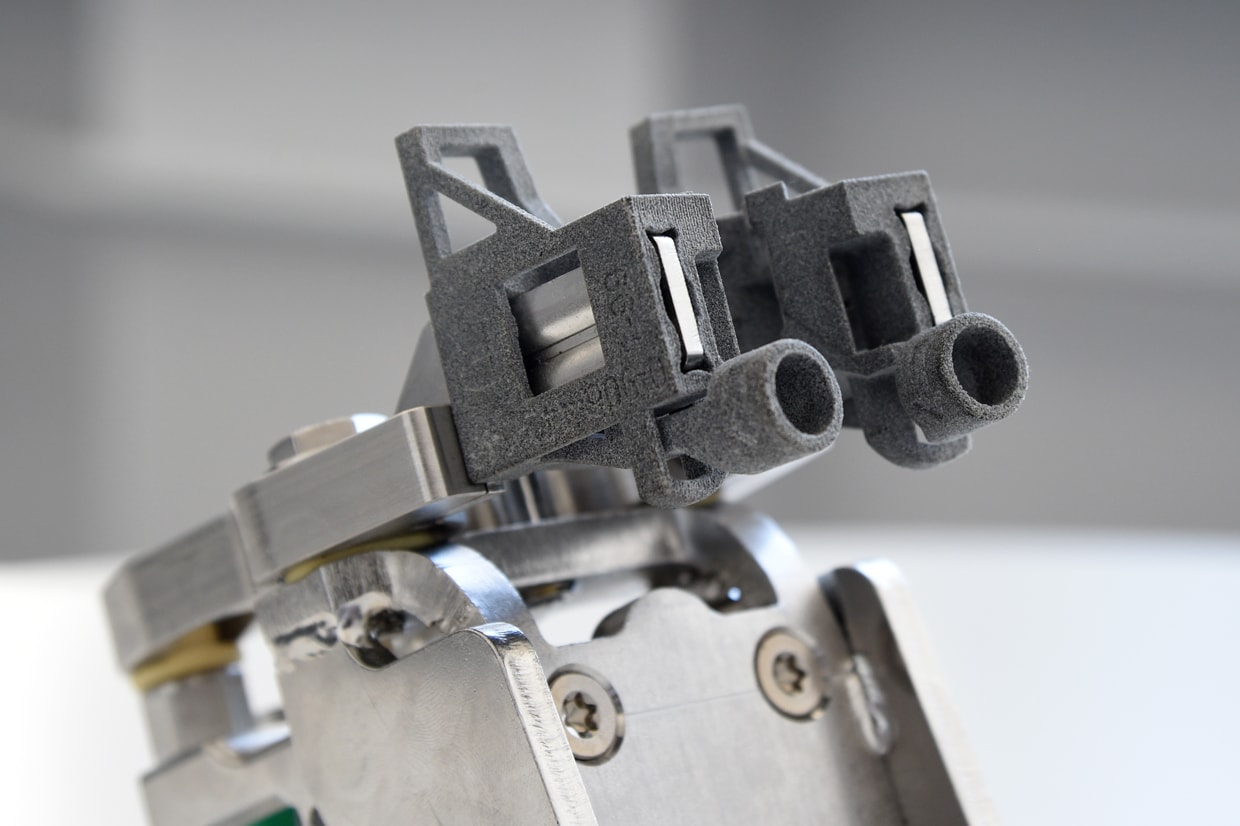

Talking about the end result – the jaw in a clamping device, two of which are needed to grip a container by the neck, can now be manufactured using 3D printing. An elastically formable spring section which can adapt to multiple container shapes and is attached to the unmachined part of the component clamps and holds the bottle. This makes the solution universally suitable, sharply reducing both manual intervention by the operator and the costs for new parts. 3D printing also allows the new clamping jaw and device to be manufactured particularly quickly – a critical advantage in an industry where market success is often decided by speed and flexibility.

The “holding jaw and clamp device for holding a container” is more than just a patent – it is a practical example of the more efficient, more flexible and lower cost future that 3D printing offers. The idea of the apprentices represents an innovative alternative to the classic clamping jaws in the rinser carousel, which is precisely why Krones also decided to apply for a patent. And the application was successful! It was granted by the German Patent and Trade Mark Office (DPMA) in September 2024. “I am very proud that everything worked out,” explains Fabian Eisenschink, who was involved in the project. “That's when I realised that even an apprentice can play an active part in shaping ‘Solutions beyond tomorrow’.”