Transforming waste into a valuable resource

In Indonesia, there is, at present, little official infrastructure for waste management and recovery – and so, it’s all the more crucial that the private sector takes the action. “The decision to establish a recycling company here was based on our shareholders’ desire to promote a circular economy for PET bottles and to transform waste into a valuable resource,” explains Suharji Gasali, managing director at Amandina. “And because we are starting out fresh, with no experience in plastics recycling, we felt it was important to have a competent, reliable partner at our side. Our shareholders have known and appreciated Krones for quite some time already. We knew that the Krones team would be every bit as invested in this project as we are and they wouldn’t let us down, even when difficulties arise.”

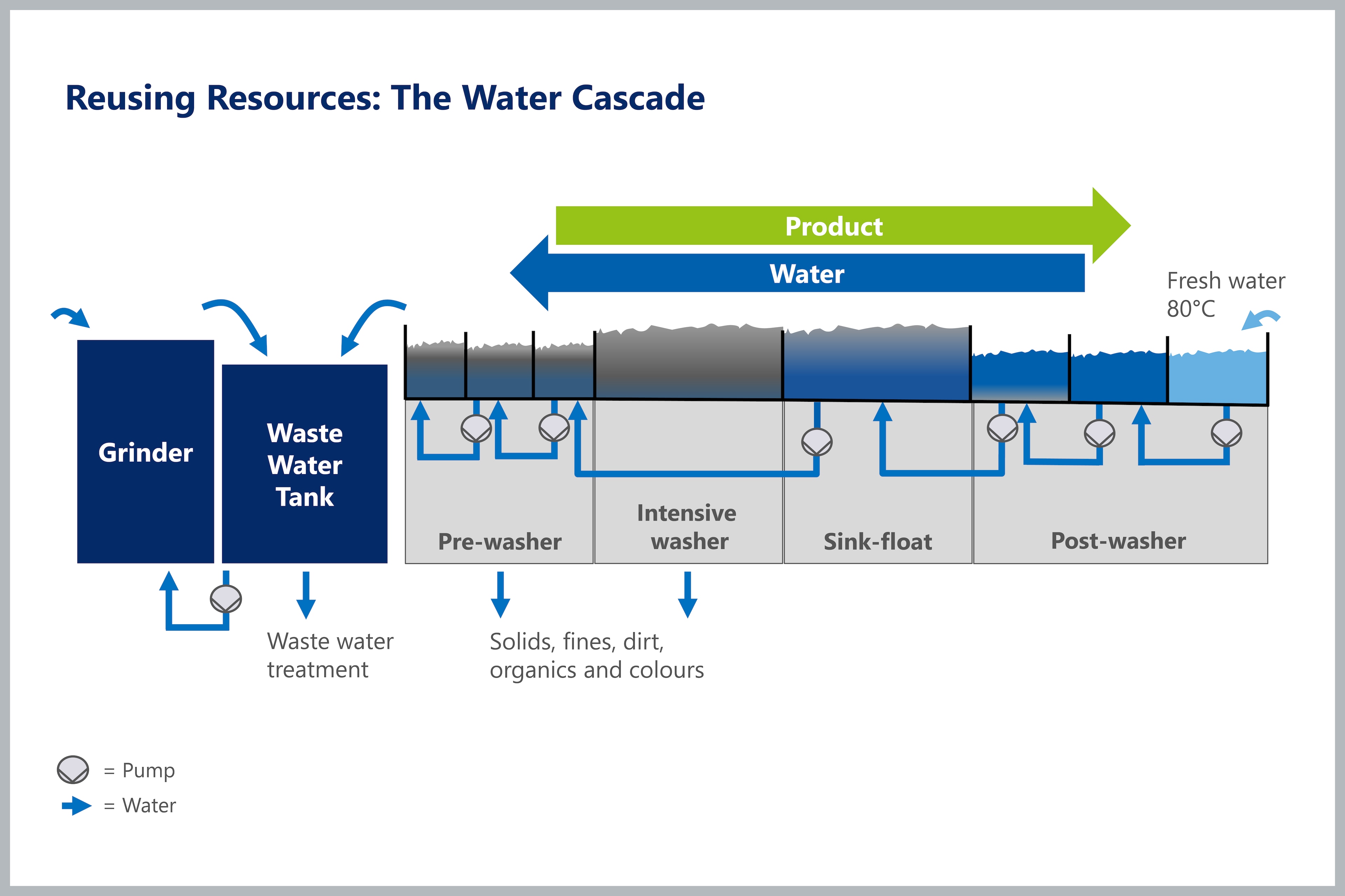

And so, Krones received the order for a turnkey recycling plant – from sorting to grinding and washing right through to packaging the clean flakes for further use. It was under the challenging circumstances of the Covid-19 pandemic, in 2021, that the cornerstone was laid for Amandina on the outskirts of the bustling metropolis of Jakarta. We might add that the plant was installed in record time.

We knew that Krones would be every bit as invested in this project as we are. That they wouldn’t let us down, even when difficulties arise.

Suharji GasaliManaging Director at Amandina

Suharji GasaliManaging Director at Amandina