Complete concept for water

As an all-round partner, we support you throughout your entire production lifecycle –from product development and factory planning, appropriate systems technology and consumables, through to after-sales business – and thus create a water that is exactly just as you want it.

The holistic expertise of Krones process technology

Analysis and formula development

We work with you to develop a formula that meets your requirements. In addition to our experienced experts, you are also supported by a certified water sommelier in order to fulfil your individual requirements when it comes to the water quality and required taste of the end product.

When is the re-mineralisation of water necessary?

Three scenarios – and always the right Krones solution

The experts from Krones design the Hydronomic systems technology to ideally suit your product –and in doing so absolutely take both the untreated water quality and the desired end water quality into consideration.

Krones combines a trained water sommelier’s wealth of knowledge with many years of experience in process technology – thus offering you accumulated expertise to create an individual formula for the remineralisation of your water. We model water samples (depending on the type/scope) just as you want them, in internal or external tests. The chemical analysis is verified by external laboratories. A water sommelier or relevant test panels at Krones are then responsible for the sensory evaluation.

Are you looking for an all-round partner for formula development and implementation? Get the most from our comprehensive network, which combines the widest range of professionals dealing with the subject of water:

- With its wealth of knowledge and experience when it comes to the treatment and production of beverages, Krones excels.

- KIC Krones provides all of the consumables and additives needed for remineralisation with the Hydronomic.

- And thanks to our cross-sectoral network, we have access to experienced partners at any time if required.

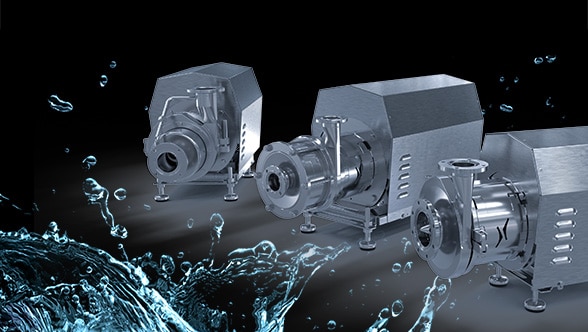

Systems expertise

With the Hydronomic series, Krones provides an individual programme for the careful treatment of your untreated water. This way, you can give your water precisely the character that suits your product and appeals to your customers.

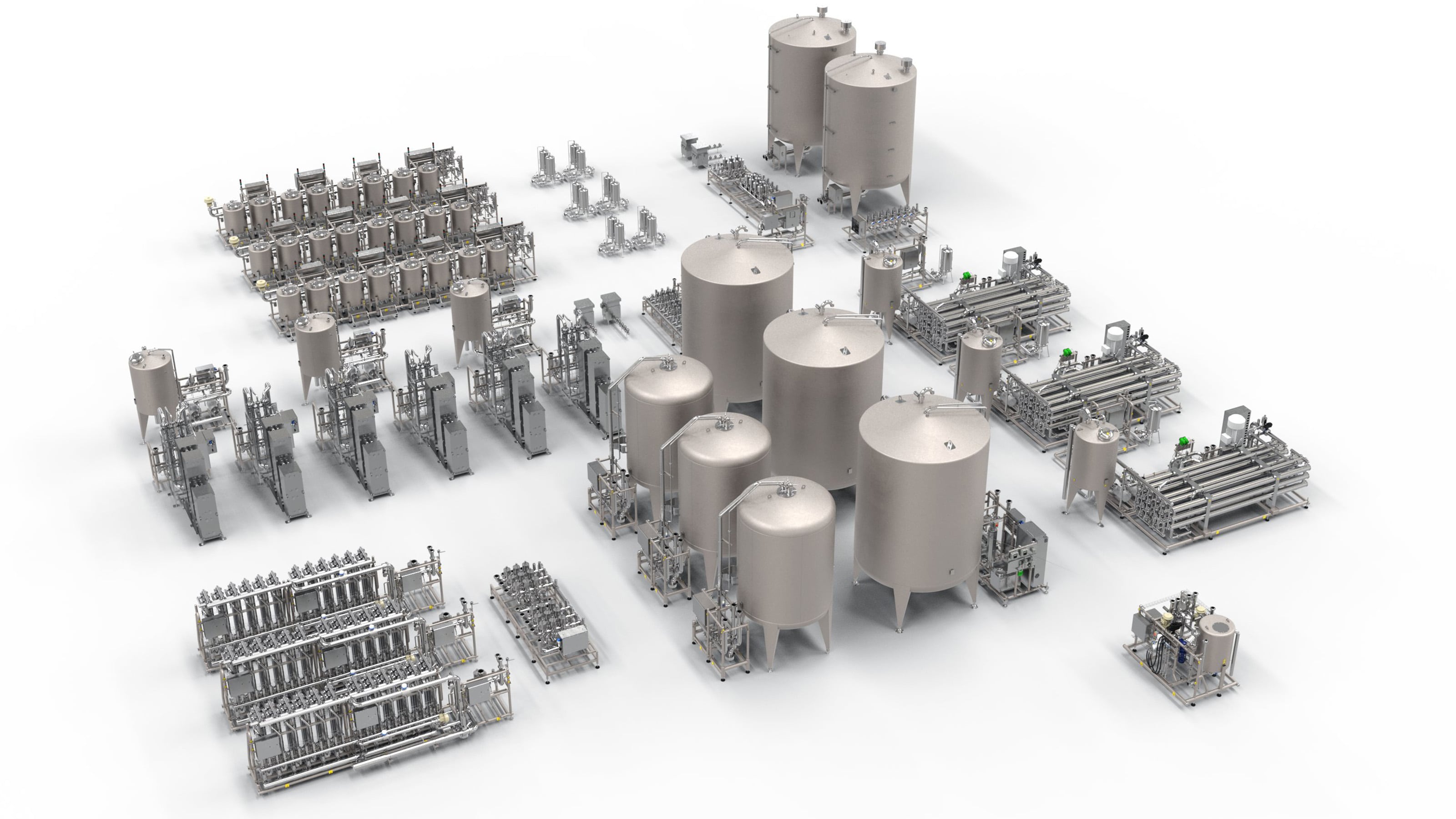

The Hydronomic series at a glance

Whether conventional mineral water, with added vitamins or flavourings, or mixed with tea or juice: water can be used in a variety of fashions – and the Hydronomic series offers modules for all steps of the treatment to create individual waters.

Cleaning module RWA

MDS module

Thanks to the use of a mineral dosing station – in brief MDS module – you can remineralise your water exactly in line with your own formulas – for the highest possible flexibility and individualisation of your product.

EDI module

Electrode ionisation (EDI) allows you to produce ultra clean, deionised water which then merely requires the addition of the desired minerals. The use of this kind of additional EDI module is particularly recommended in cases where the untreated water quality fluctuates. This is particularly important in the manufacture of still table water where there must be no deviation in the mineral composition of the product.

Hydronomic RO (Reverse Osmosis)

The Hydronomic RO module serves to desalinate water down to a usual residual content of less than three percent. The generated water is then especially treated/remineralised for the respective application.

Hydronomic UF

The Hydronomic UF uses the most up-to-date membrane technology with hollow fibres (pore size of 0.02 μm) for the ultrafiltration of water in in/out operation. Typically, ultrafiltration is also used to extend the production time of an (optional) downstream reverse osmosis system by additionally filtering the water.

Hydronomic MF/GAC

The module filters and adsorbs any unwanted and undissolved water content (suspended solids, odorants, organics, chlorine, iron, manganese, etc.) with different filter media (e.g. silica sand, manganese oxide, basalt and activated carbon).

Benefits to you

- It operates with a water treatment process which is tailored exactly to your requirements

- It prepares between 5 and 120 cubic metres of water per hour – optionally with a variable production quantity

- Minimised quantity of waste water thanks to its sophisticated technology

- Best possible access for operators and service personnel

- It can be expanded thanks to modular design

- Hygienic design throughout:

- Guarantees the highest microbiological safety and reduced cleaning work

- The stainless steel design allows for complete sanitation with hot water

Combination of Krones process and filling technology

Regardless of which Krones filling method you choose, we offer the corresponding treatment technology to sustainably ensure the microbiological stability and quality of your product:

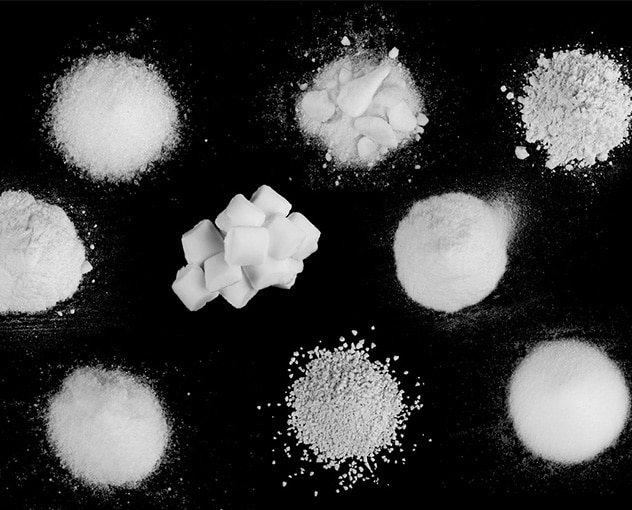

Minerals and consumables from KIC Krones

As part of a water design from Krones, you also receive all of the minerals needed for ongoing operation. As an expert for consumables, KIC Krones also supports you in the areas of water treatment and water design with its expertise and ideally adjusted products:

- Mineral salts for the regeneration of ion exchangers and mineral dosing

- Mineral salts for the regeneration of ion exchangers and mineral dosing

- Cleaning agents and disinfectants for the complete water treatment system

- Filter elements for the filtration of liquids, compressed air, gas and steam

- Granular filter media such as quartz gravel and activated carbon

- Granular filter media such as manganese dioxide, ion exchange resin, etc. (on request)

- Membranes for ultrafiltration and reverse osmosis (on request)

- Cleaning agents and disinfectants for the complete water treatment system

- Filter elements for the filtration of liquids, compressed air, gas and steam

- Granular filter media such as quartz gravel and activated carbon

- Granular filter media such as manganese dioxide, ion exchange resin, etc. (on request)

- Membranes for ultrafiltration and reverse osmosis (on request)

- Are ideally adjusted to Krones systems technology

- Are selected based on the globally varying local conditions and untreated water quality

- Reliably remove all undesirable substances from untreated water, for example undissolved solids, iron, manganese, arsenic, chlorine, bacteria, viruses, etc.

- Support you in manufacturing an end product which precisely meets your requirements and concepts

- Satisfy the high standard demanded by the food and beverage industry

- Are ideally adjusted to Krones systems technology

- Are selected based on the globally varying local conditions and untreated water quality

- Reliably remove all undesirable substances from untreated water, for example undissolved solids, iron, manganese, arsenic, chlorine, bacteria, viruses, etc.

- Support you in manufacturing an end product which precisely meets your requirements and concepts

- Satisfy the high standard demanded by the food and beverage industry