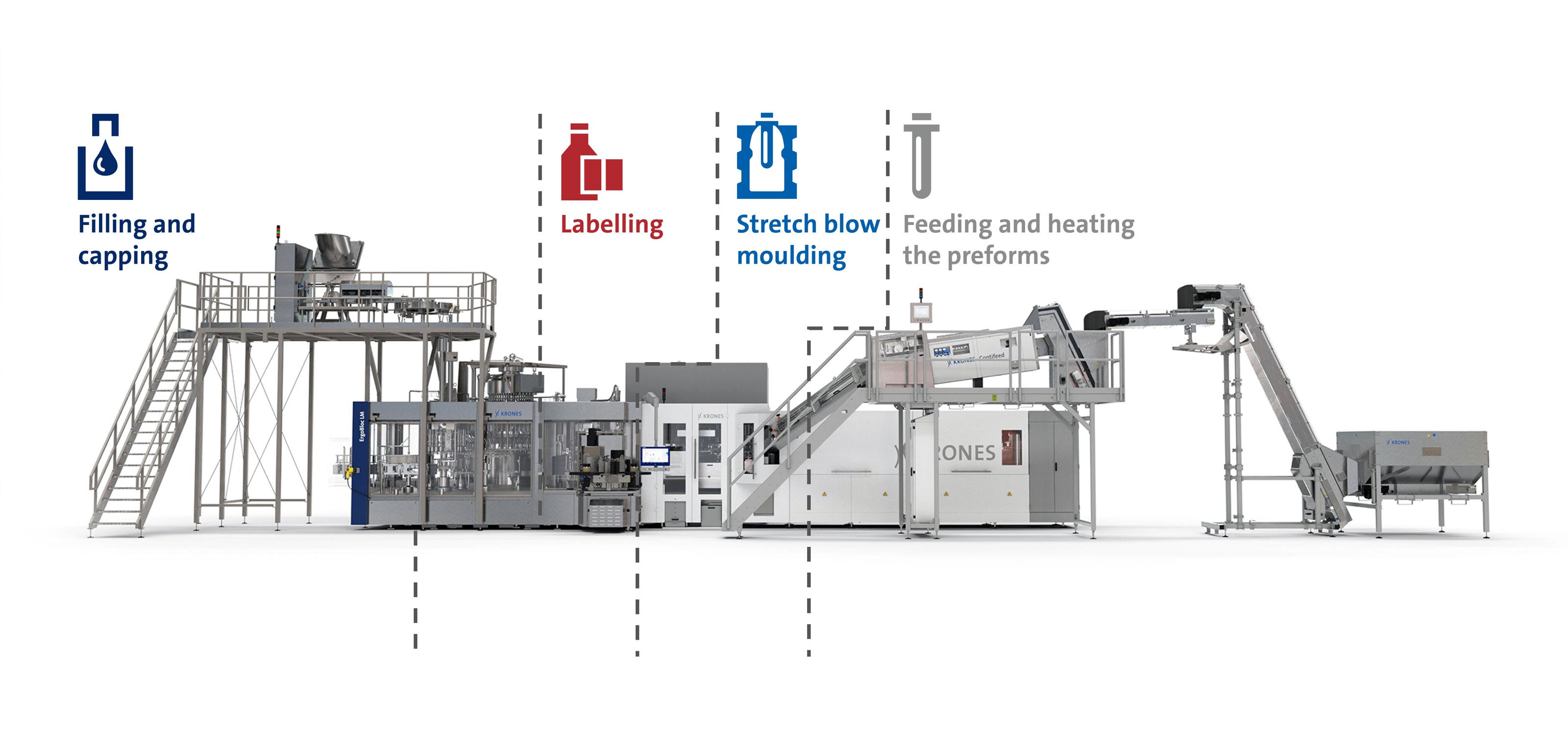

The block solution for non-carbonated and/or flavouerd water

Well though-out block philosophy

The ErgoBloc LM promotes block technology decisively. How that? It represents the block concept with a determination that is unrivalled. The ErgoBloc LM does not only combine individual machines but it also is designed as a holistic system with one central unit each for the control system, the drive and the operation.

At a glance

- Functions: Stretch blow moulding, labelling, filling and capping

- Output: up to 55,000 containers per hour*

- Processing range:

- Non-carbonated and/or flavoured water

- Cylindrical containers made of PET

- Standard and lightweight containers

- Container volume up to 2.0 litres

- Containers of up to 100 percent rPET

- Plastic reel-fed labels

*depending on the processing range

LM = Liquid Medium

The design

- Up to 30 percent less space requirement in comparison to conventional block variants

- Uniform lubrication and safety concept and drive control

- Central HMI for complete operation and PLC for all control functions

- No transfer starwheels between the main modules

- Operation possible with one single operator

Components

- Torsion-resistant platform with skip-and-run technology

- Only four internal horizontal preform and container transfer points

- Actively controlled transfer grippers

- Five high-precision Monotec servo motors with real-time synchronisation

Infrared heating technology

- Parabolic reflector for top infrared emitter

- Adjustable base reflectors: adjustable to the respective preform length

- Maintenance-free system of ceramic reflectors

Air Wizard Triple

- Further developed compressed air recycling system with intermediate pressure levels for internal re-use of the compressed air

- Automatic self-optimisation of the blowing air recycling process

- Significantly reduced switching time dispersion

Why label first and fill afterwards?

- Full bottles can have varying internal pressures.

- These variations can impact the labelling result.

- The bottles do not have any unwanted moisture.

Solution: The ErgoBloc LM ...

- labels the bottles before filling them.

- pressurises the empty bottles with compressed air.

Result

- Consistently excellent label fit

- Optimum conditions for lightweighting

- Ideal access for handling parts change-over

- Optimal accessibility from three sides

- "No bottle – no label" function

- Reduced hotmelt consumption due to "Gravure Glue Application"

- Unique servo motor technology

- Flexible selection of the pitch

- Maximum stable handling of thin, sustainable films

Benefits to you

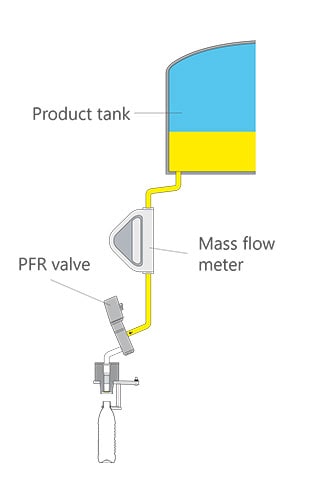

- Mass flow meter for precise dosing of conductive and non-conductive water

- State-of-the-art hygienic design

- PFR filling valve

- Variable filling speed control

- Electronic controller integrated directly in the valve

- Product tank

- Product feed from top

- Complete draining possible

- Omission of rotary media manifold

- Labyrinth seal for protection against contamination

- Tabletec front table

- Slanted plate with central drain

- Lubrication-free drive

- Smaller clean room volume

Bottle design and moulds

Creative and in line with the market

At a glance

- Four production centres worldwide with state-of-the-art manufacturing technology

- Container design experts at all four locations

- Design and production of mould types for all Contiform series

- Mould validation on our own technical centre systems

Benefits to you

- Customer-oriented consulting: Creative, functional, unique

- Individual designs with a view to customer requirements and feasibility in the beverage line

- Experience from more than 20,000 moulds per year

Benefits to you

Four process steps – one operator

The block is designed as one unit in which all essential control and function elements are centrally combined. This way, just one operator can easily operate the entire ErgoBloc LM on his own.

Energy savings

From optimised infrared heating technology to consistently implemented servo drive technology: The topic energy efficiency goes all the way through the block just like a red thread. Especially ambitious savings goals can be realised with the Air Wizard Triple compressed air recycling system.

Focus on the essentials

The ErgoBloc LM has been planned as a single, integrated machine and it is designed exactly for one defined application. This allows to go without many cost-intensive elements. Therefore, it only needs one central touch-screen for all functions and only requires one single labelling station.

Cost-efficient customisation

The pre-defined option packages enable to adapt the block to special requirements and keep the costs as well as the commissioning time low at the same time.

Trouble-free continuous operation

Full power with no breaks: The labelling module automatically detects bottle gaps and does not apply glue or labels in this case. Disruptions due to missing bottles and unnecessary glue and label consumption are therefore not an issue.

Small footprint

The ErgoBloc LM requires up to 30 percent less space than conventional block variants.

Beverage containers made from rPET

Material properties, processability, food grade quality: you can find all kinds of interesting facts about the use of recycled PET in our free white paper.

This is why the ErgoBloc LM is enviro-classified

Energy efficiency

- Increased station performance during stretch blow moulding and labelling

- Reduced energy consumption thanks to the omission of transfer starwheels and redundant components

- Lowest possible heating energy requirement through energy optimisation of heating zone and heaters

- Energy-efficient separated vacuum during labelling

Media efficiency

- Efficient cooling of the entire block

- Air Wizard Triple compressed-air recovery system

- No compressed-air consumption during the filling process

Environmental compatibility

- Use of enviro-compliant lubricants

- Recoverable CIP media