Tripod solution for the palletising technology

The next step in evolution

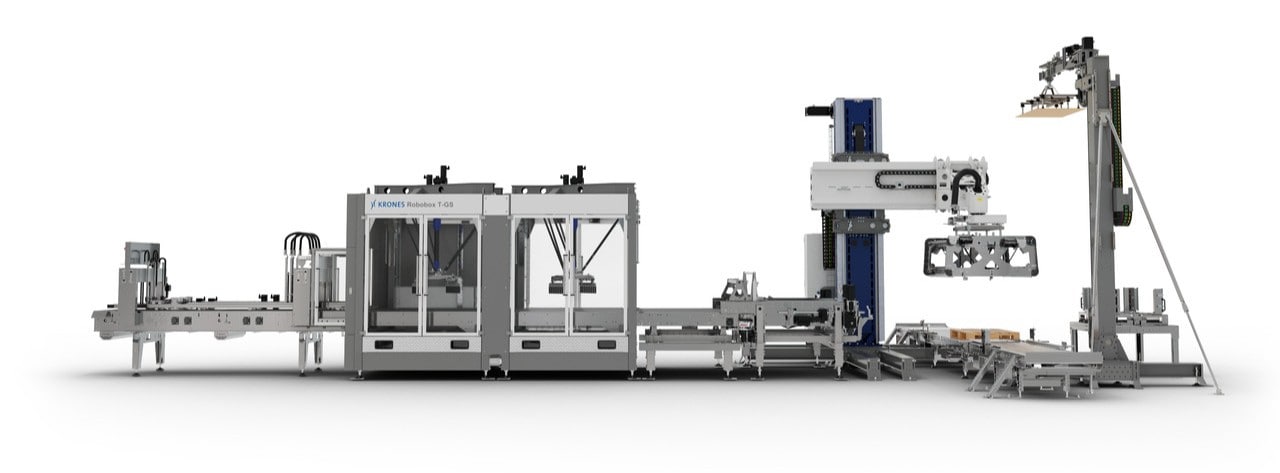

The grouping system Robobox T-GS uses tripod robots with innovative parallel kinematics. This makes it faster, more robust and more precise than conventional grouping systems.

At a glance

- Grouping of packs in line with a specified layer pattern

- Processing range: All commercial non-returnable packs

- Top grouping speeds with only one module

- Reduced space requirement

- Shorter infeed lengths between the packer and palletiser

- Less maintenance and service work required thanks to steady, more harmonious movements

- New ergonomic feed with separate service and operating side (requires TIA control)

T-GS = Tripod Grouping System

Technical features

RoboboxT-GS is a modular system which positions the non-returnable packs for the determined layer pattern. Positive-fit precision grippers guide the packs safely and gently to their pre-programmed position.

- One or two-lane pack infeed (clocked or continuous gap-free)

- Gripper head for positioning single or several packs

- Robot with parallel kinematics

- Gripper technology for all industry-standard packs, carton and shrink-wrapped packs as well as single packs

- Option: Automatic adjustment of the infeed conveyor guides

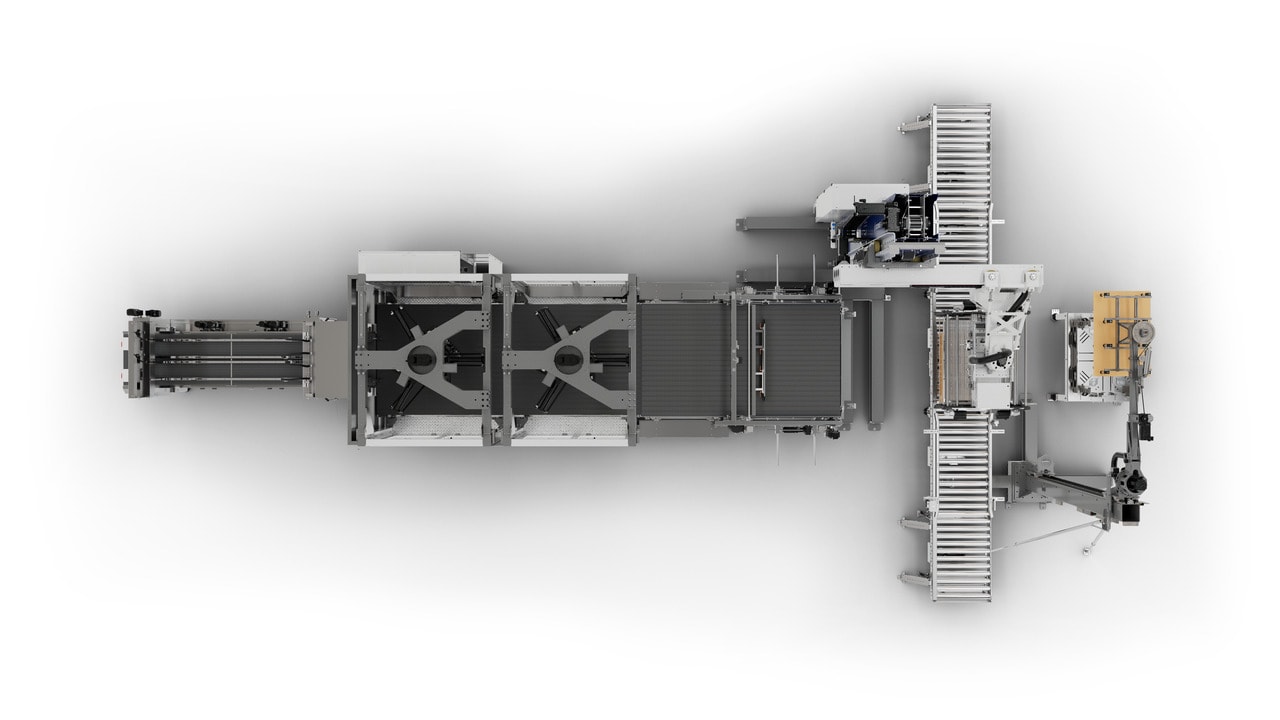

Example for overall arrangement

Practical modular component system

A double-module RoboboxT-GS may be used to adjust the speed of the grouping system exactly to that of the entire line.

A winning team

Together with the palletising robots of the Modulpal Pro series, the Robobox T-GS forms a flexible and fast-acting system that is capable of achieving top performance in palletising.

Benefits to you

High outputs with compact design

Being a high-performance tripod robot, the Robobox T-GS groups up to 500 layers per hour with only one module.

Precise layer patterns

Positive-fit precision grippers guide the packs reliably and precisely to their intended position.

Gentle pack conveyance

Due to the fact that there are no transfer plates between the flush-grid belt tables, the packs are conveyed extremely gently. And another thing: Stop-and-go is a thing of the past thanks to the continuous infeed. The packs enter the grouping station continuously with very low impact.

Simple design

Due to its innovative parallel kinematics, the Robobox T-GS must move up to 70 percent less of its own mass than an articulated-arm or portal robot.

Intelligent correction mode

The grouping system checks the position of the incoming packs and regulates it upon deviations.

Efficient team

Depending on the respective task, the grouping system can be combined with additional machines from the Krones dry part. An especially effective combination: In a team with the Modulpal Pro 2A palletising robot, the Robobox T-GS achieves great performances on small space.

Fast product change-over

In order to keep change-overs as short as possible, the Robobox T-GS requires hardly any product-specific components.

Flexibility and efficiency

Depending on the requirements, the infeed comprises either one or two lanes. It is also possible to position several packs simultaneously.

Why the Robobox T-GS is enviro-classified

- It is only used with servo drives of efficiency class IE4

- Significant reduction in the moved masses thanks to parallel kinematics and carbon components

- Energy recovery via the modular B&R ACOPOSmulti drive system

- Energy measuring package and leakage detection

- Almost no pneumatic drives and locking systems to a large extent

- Use of enclosed lifetime-lubricated bearings

- Employment of enviro-compliant H1 lubrication grease and oil