Heat even exacting products

Efficient product heating

Efficient product heating based on heat exchanger systems with heat exchanger surfaces exactly adjusted to suit the characteristics of the product. Krones systems gently heat your products, ensuring microbiological safety and, above all, with substantially reduced energy consumption.

At a glance

- Are suitable for a wide variety of products with different flow characteristics (even for products containing particles/fibres)

- Reduce the thermal impact acting on the product due to low dwell times

- Are available as complete system or individually designed to suit your line

- Field of application in the Krones product portfolio

- Pasteurisation: VarioFlash J and VarioAsept J

- Ultra-high heating: VarioAsept M

- Hotfill: VarioFlash H

Optimal planning of the thermal product treatment will result in a reduced ...

- thermal impact acting on the product due to the short dwell times.

- requirement for thermal and pump energy.

- portion of product loss due to reduced line volumes.

- oxidation rate if a VarioSpin product deaerator is used.

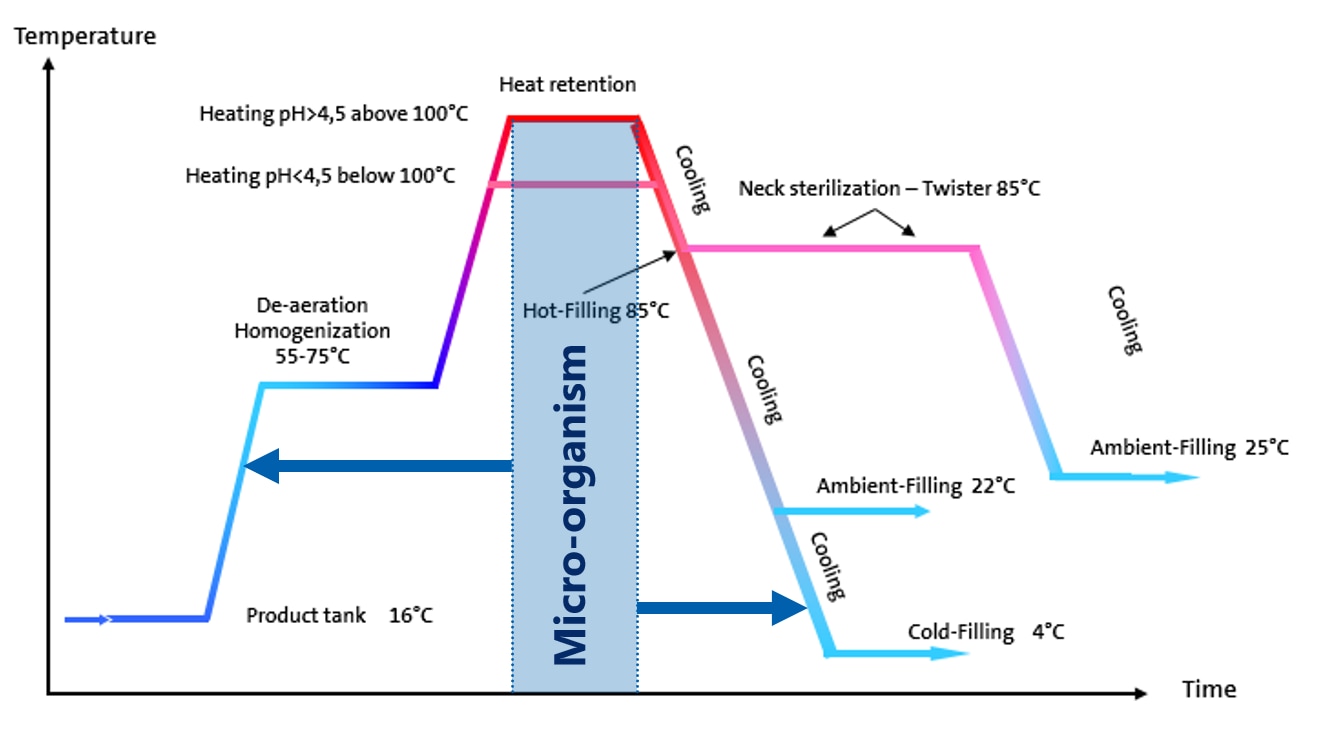

The heating temperatures and periods are defined by the killing kinetics of the various micro-organisms. An optimum design of the heat exchanger surfaces can reduce the dwell time in the heating and cooling zones. It is essential to find the correct balance between the least possible number of tubular modules (optimisation of the heat exchanger surface) and gentle product heating.

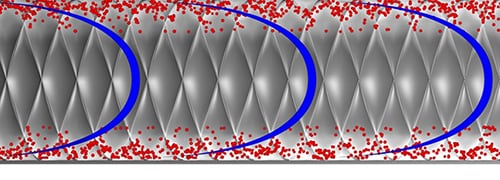

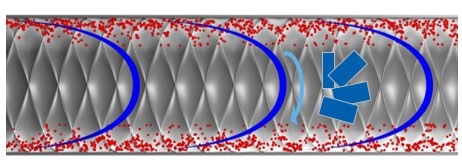

Thermal product treatment with cross-corrugated tubes

The use of cross-corrugated tubes increases the flexibility of product treatment with regard to output range and product variety. Due to their surface structure, cross-corrugated tubes can break up the laminar boundary layer which results in a high turbulence and positively affects the further output

and/or viscosity. This can reduce the required surface of the heat exchanger by up to 30 %.

At a glance

- Low thermal load

- Short heating and cooling phases

- Low loss of flavour and vitamins

- Minimum colour change (e.g., for tea)

- Preservation of the natural product quality

Cross-corrugated tubes

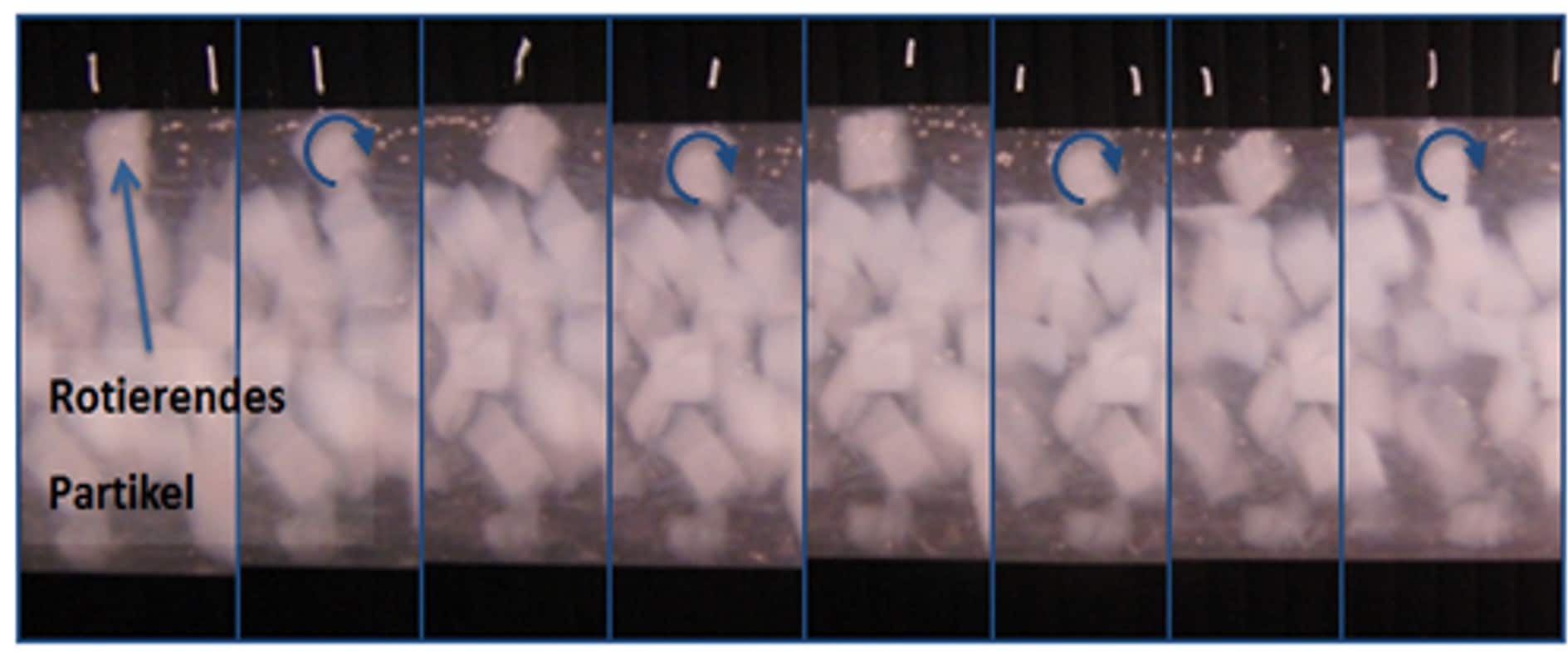

Treatment of products containing particles

- Highly concentrated suspensions of fruit pieces and juice (for instance fruit mixtures which are treated in twin-flow mode) tend to laminar flow behaviour. Main features are the comparatively fast core flow and the overheated outer zones.

- The cross-type swirl gently rotates the particles. The structure of the cross-corrugated tubes

- breaks open the laminar boundary layer.

- ensures even distribution of the fruit pieces in the tube.

- prevents partial underpasteurisation in the core flow.

Your benefits from a more efficient and, at the same time, reliable heating

- Reduced flow speed

- Reduced pressure level

- Reduced damage rate of the fruit pieces

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

Benefits to you

Specific configuration of the product treatment system

Thanks to special Krones measuring and configuration programs, you will be provided with customised heating systems which are based on precise data and exactly adjusted to suit the characteristics of your products.

Modular design

Thanks to its flexible design, the Krones heat exchanger is available in two sizes: one compact variant for low outputs and one high-end design for medium to high output ranges.

Gentle product treatment

Our special tube modules with cross-corrugated section enable a quick heat transfer and, at the same time, high recovery efficiency. As the mixture phase quantities are reduced to a minimum, the required heat exchanger surface and thereby the thermal stress, as well as the pressure and product loss are reduced as well.

Reliable cleaning

Thanks to a design with reduced dead space, all product contacting surfaces can easily be cleaned.

Comprehensive concepts for process technology

In addition to heat exchangers, Krones also offers compact and space-saving units for product deaeration, heating and product mixing, as well as process water sterilisation and CIP/SIP systems.