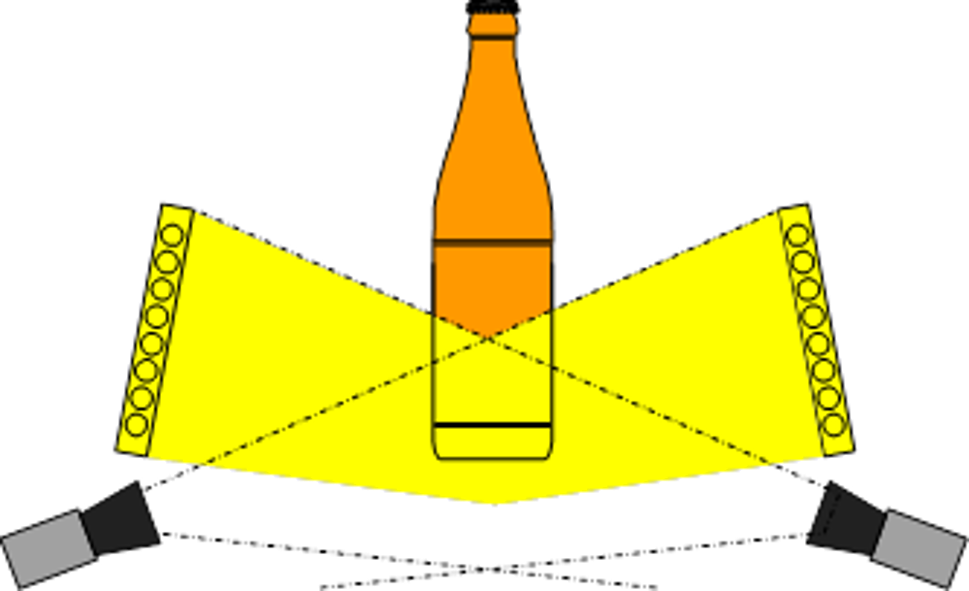

Detection of foreign particles in bottles

Maximised product safety with high-precision bottle inspection

What should be in your containers after filling? Exactly: the beverage - and nothing else. The Linatronic 774-C ensures that there are no unwanted surprises when you enjoy your products. This is because it takes a close look at every container and unerringly detects both foreign particles and even the smallest damage.

At a glance

- Inspection of full containers

- Suitable for glass and PET containers

- Inspection modules for glass containers:

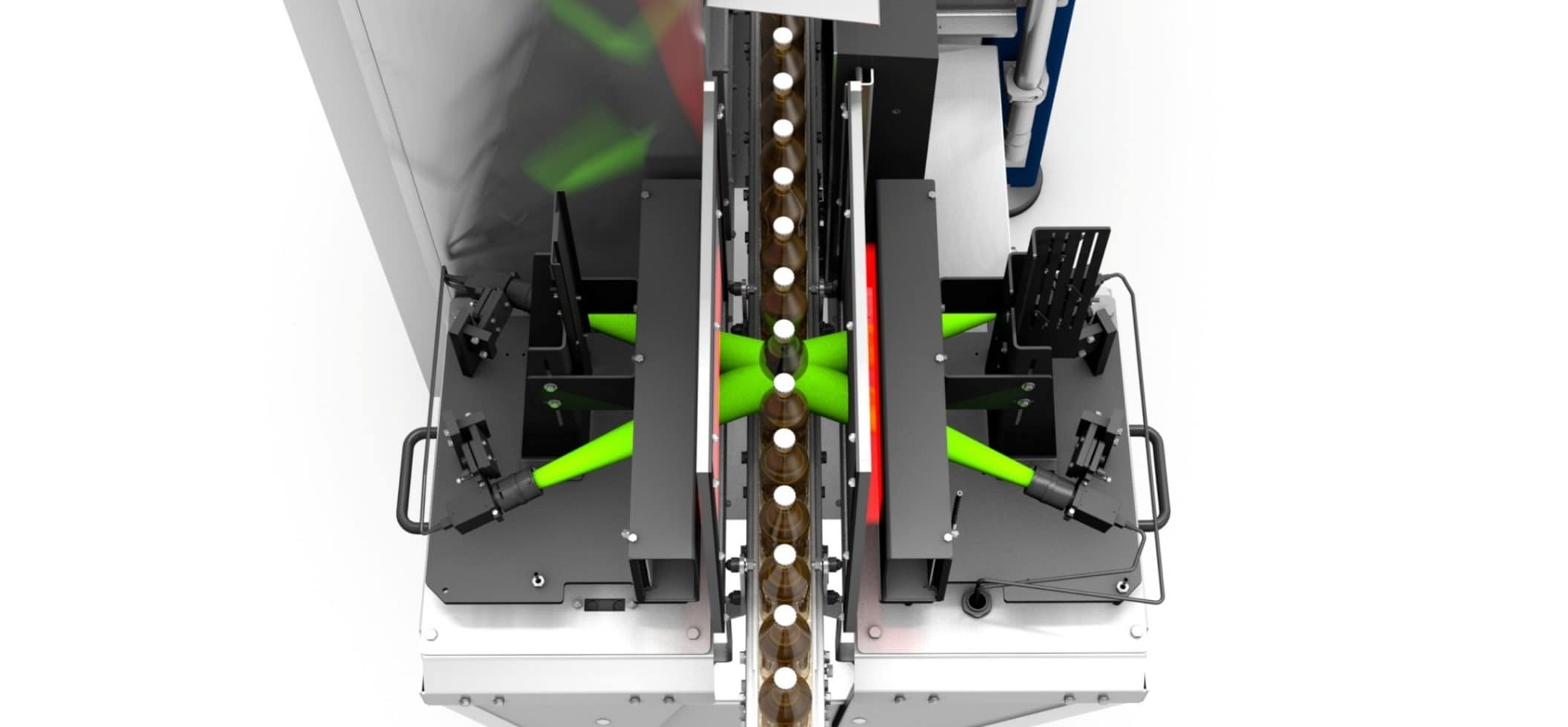

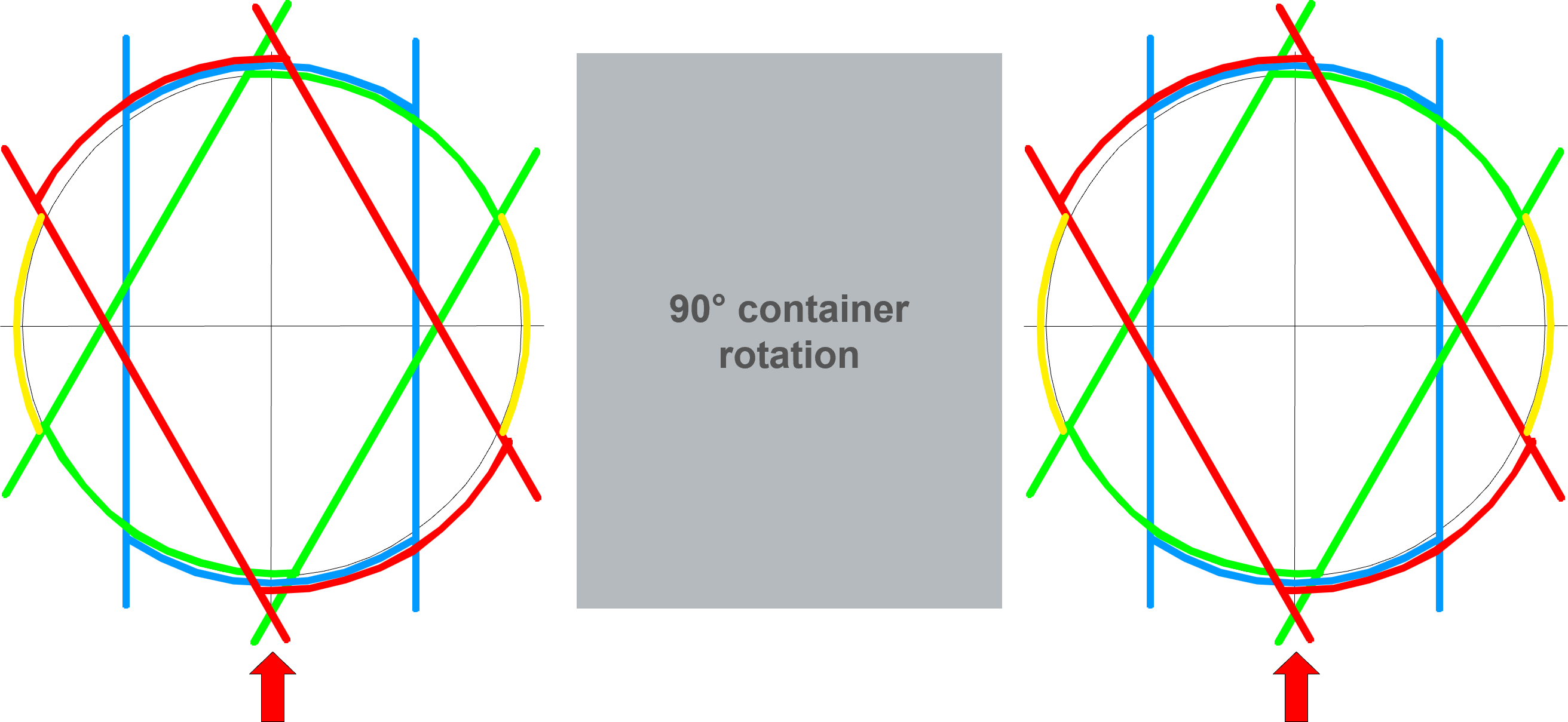

- Lateral base inspection

- Suspended matter inspection

- Base inspection unit (bright field)

- Inspection modules for PET containers:

- Lateral base inspection

- Suspended matter inspection

- Detection of floating objects

for glass and PET

for glass containers

| Inspects glass containers/cap for the following: | |

| Leaky caps | At products containing CO2 |

| Hairline cracks and chipping in the area of the neck | |

| Missing compound liners | |

| Mechanical deformation on crowns |

Technical features

- Output up to 75,000 bottles per hour

- Suitable for containers with crowns, twist-off and ring-pull caps

Benefits to you

Long-life conveyor belts

Particular care was taken when selecting the surface of the conveyor belts. It is more resilient to glass and prevents the absorption of lubricants and liquids.

Quick type change-over

The automatic adjustment of conveyors and the camera position ensure that the Linatronic is adjusted to new container types within just a few minutes.

Immediate round-the-clock assistance

With the GRS remote service platform your machine is directly linked with the Krones service department: If you require assistance, an inspection expert from Krones simply accesses the Linatronic online and immediately performs the task in hand – without having to travel to your company, at any time of the day or night.

Economic operation

Inspection modules capable of multitasking, energy-saving components and a false rejection rate of just 0.3 percent prove that it is also possible to create maximum production reliability with a low total cost of ownership

Safety for you and your products

The Linatronic protects your consumers against unpleasant surprises. For its inspection modules scrutinise every container and detect event the smallest defects or irregularities.

Hygienic construction

Smooth surfaces and a reduced number of machine supports ensure that a low amount of dirt clings to them and the machine is easy to clean.