Sustainable packaging solutions: Conserving resources with Krones

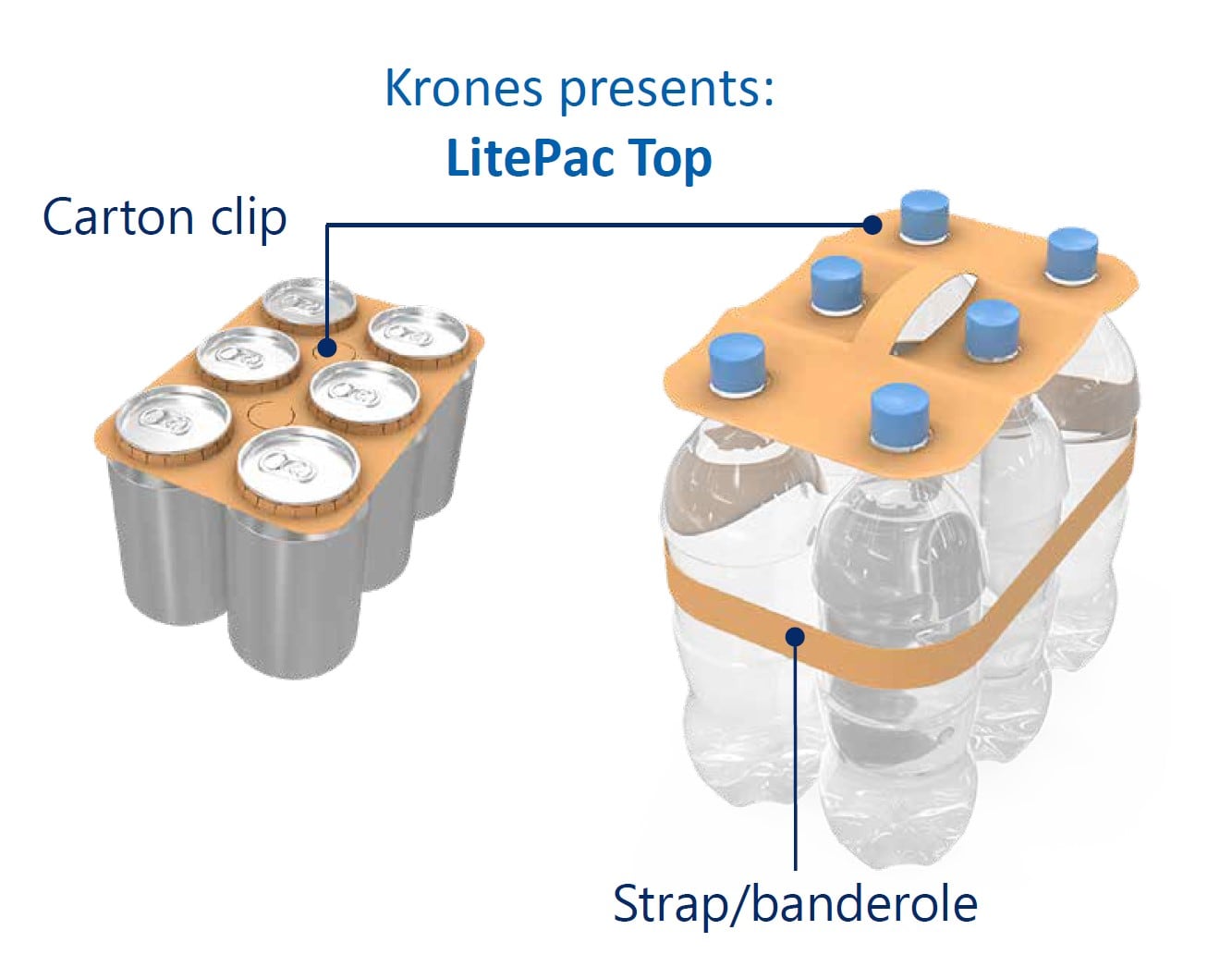

When it comes to reducing the use of materials, we mostly think of the primary packaging first. But if we take a closer look, we can see that there is also plenty of savings potential with secondary packaging. LitePac Top stands for a new packaging solution comprising a carton clip and possibly other pack securing, such as a banderole.

At a glance

The sustainable LitePac Top secondary packagings ...

- are suitable for PET bottles and cans.

- offer a sustainable alternative to shrink film packs.

- combine minimal use of materials with great user friendliness.

- can be made of corrugated cardboard or kraft cardboard depending on the intended use and can be recycled after use.

Plastic-free packaging for PET packs

Renewable, sustainable paper-based packaging replaces shrink packaging

- Cardboard clip underneath the bottle neck holds the containers in the required formation

- Stable and safe design for storage and transportation

- Consists entirely of renewable raw material

- Integrated carrying strap on cardboard basis for easy gripping

- Banderole

- Tear-resistant, printable kraft paper, fully recyclable

- Guarantees reliable transportation and provides a functional surface (for example for bar code masking or individual print)

Benefits to you

- Complete packaging is 100 percent recyclable after use

- Lower greenhouse gas pollution compared to shrink film

- Makes it easy to remove the individual bottles

In summary

- Pack formations: 2 x 1, 2 x 2, 3 x 2

- Processing range: Up to 2.0 l PET bottles

- Krones enables maximum flexibility when it comes to selecting the packing materials supplier

Cardboard clip for cans

Benefits to you

- Of renewable raw materials

- Free from plastic materials

- Minimal use of packaging material

- Fully recyclable

- Easy to open and comfortable to carry

Overview

- Processing range: 0.150 up to 0.568 l cans; larger cans of request

- Processing of conventional can types: Standard, slim/sleek

- Pack formations: 2 x 2, 3 x 2, 4 x 2

- Machine technology: Expansion of the proven Krones packers Variopac Pro modular machine component system for additional functionality

- Krones enables maximum flexibility when it comes to selecting the packing materials producer

Benefits to you

Independent in the procurement of packaging materials

Krones offers an open platform which largely gives the option of freely selecting the packing materials supplier (following a prior specification check).

Practical and ergonomic

The LitePac Top packs meet consumer requirements of the consumers – for example, by ensuring that they are comfortable to carry and easy to open.

Optimised solution for the entire supply chain

The stability of the packaging units is completely assured from the bottler through logistics to the point of sale – and matches the stability of shrink packaging commonly used today.

Huge savings potential

Minimal materials and low energy consumption in production: All in all, significant advantages can be achieved with LitePac Top packs – both in terms of the environment and cost efficiency.

Closed loop

LitePac Top packs follow the principle of circular economy, as they can be recycled after use.

Easy integration in bottling lines

The packers Variopac Pro modular machine component system makes it possible to create secondary and tertiary packaging on just one machine. The machine technology can be easily integrated in existing lines.