Filling with the twin-flow method

Treats juice and fruit pieces separately

The quality of juice is not only defined by its taste but also by the feeling in the mouth. The Krones dosing systems are the solution for all bottling plants that strive for top product quality and wish to lean on a high-standard fruit juice production as compared to the conventional hot filling process.

At a glance

- Application: Beverages with fruit components, such as premium fruit juices or mixed milk beverages

- Processes food pieces or fruit components of all kinds and consistencies

- Doses fruit pieces with a size of 10x10x10 millimetres independent from the aseptic filling or hot filling process

- Processes fruit and juice separately and therefore reduces damage on the fruit pieces to a minimum

The twin-flow method

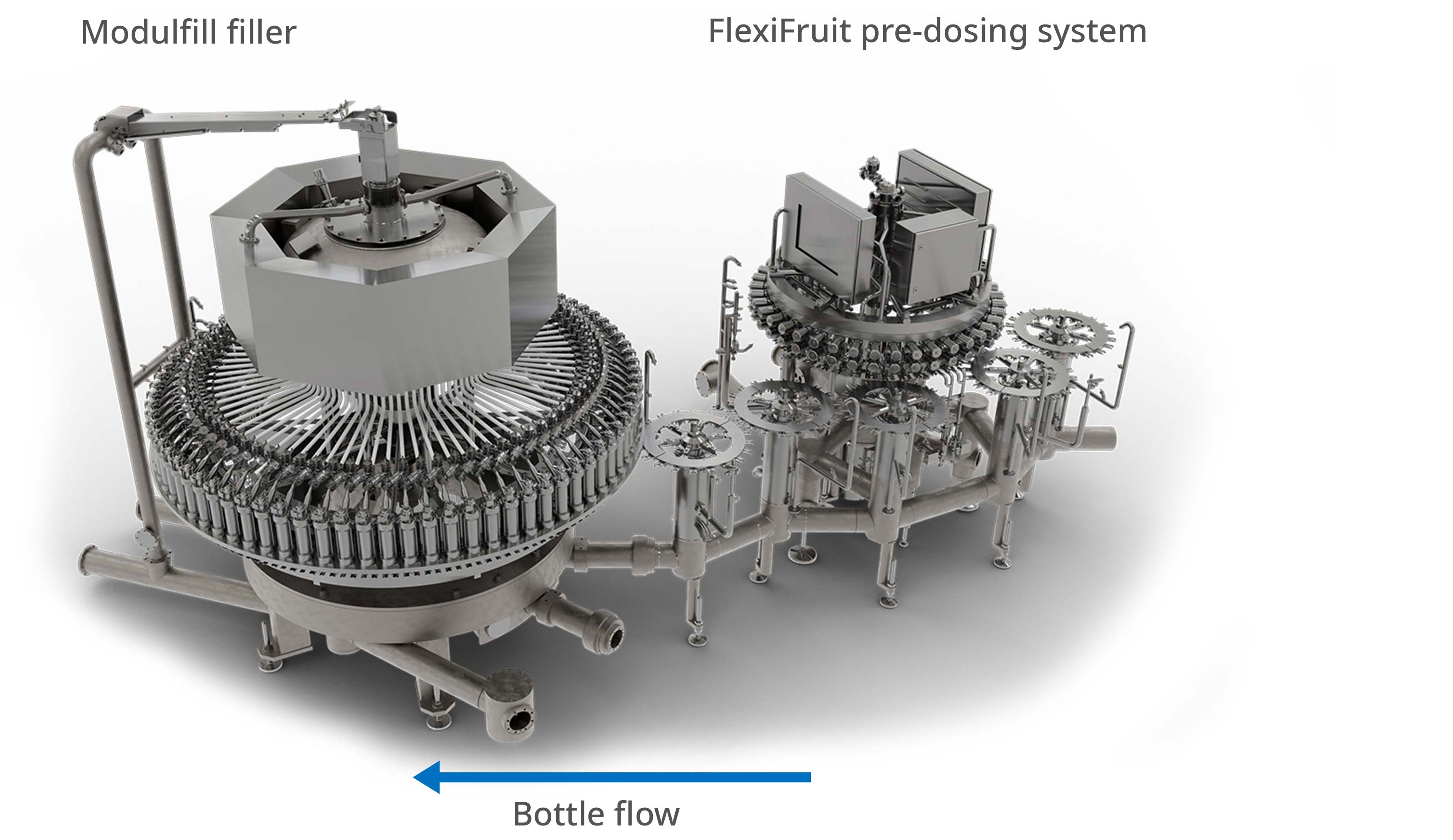

Krones FlexiFruit is an intelligent and self-adjusting pre-dosing system which controls the dosing quantity on its own via the Modulfill filler.

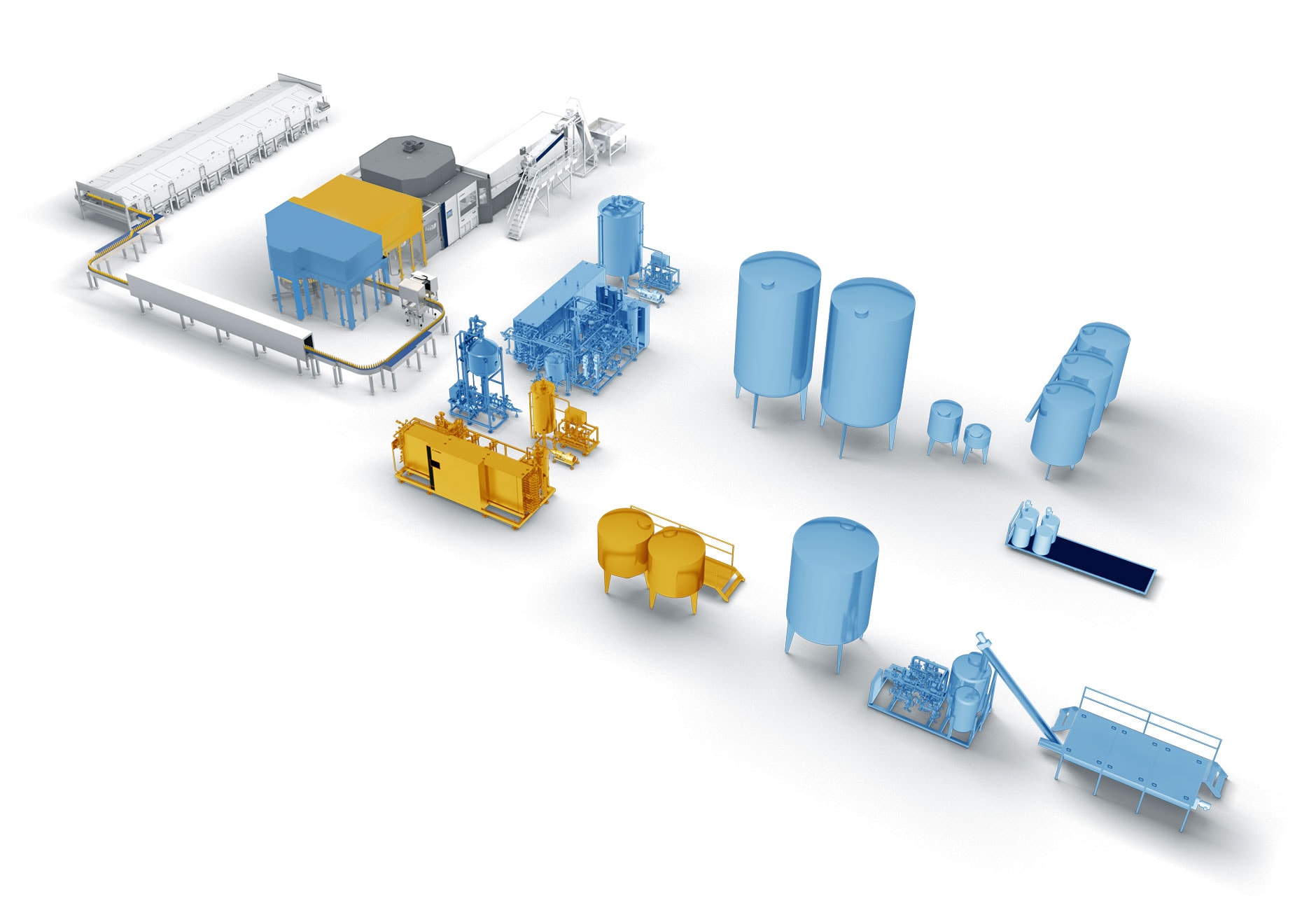

- The juice flow (main flow) is briefly and conventionally heated with the plate heat exchanger and deaerated to reduce oxidation products.

- At the same time, the flow of particles is heated separately in special tubular heat exchangers and fed by means of pumps that are gentle on the product.

Mixing of the two components:

- The FlexiFruit pre-dosing system doses fruit pieces with a size of up to 10 x 10 x 10 millimetres into the empty containers.

- The Modulfill filler fills the juice portion hot into the containers which already contain the fruit pieces.

Twin-flow procedure: Fruit flow (yellow) and juice flow (blue)

Benefits to you

Top product quality

Separate processing of fruit and juice reduces the damage rate to an absolute minimum thus allowing even highly sensitive sacs to be filled into the bottle in a good condition.

Low operating costs

The entire line has four clever details which provide a media, raw material and energy-efficient production such as smooth operating agitators which prevents product loss or flash pasteurisers for separate treatment of the product flows.

High-precision dosing quantity

The fruit pieces are dosed to the products not earlier than at the point of filling. This way, predefined quantities can be exactly maintained and cost-intensive overdosing is no longer an issue.

Complete line from a single source

The twin-flow procedure is designed as a complete solution and it is equipped with uniform materials, recurring components and a consistent software solution. Process and filling technology seamlessly integrate into each other to one perfect unit.

This is why the FlexiFruit is enviro-classified:

Energy efficiency

- Heat exchangers with high energy recovery customised to the customers' products

Media efficiency

- Minimum use of raw materials thanks to a high homogeneity during the process and precise dosing directly into the empty container