The Krones Center in Kenya has been relying on young, locally trained technicians for some time now. In order to guarantee them the best possible qualification following the German apprenticeship model, Krones is now participating in the construction of a vocational school in Nairobi. There, the trainees have the opportunity to learn both theory and practice in order to become versatile and excellently trained specialists with a broad basic knowledge.

Krones’ dual training programme in Nairobi, Kenya, brings forth its own excellently trained service technicians.

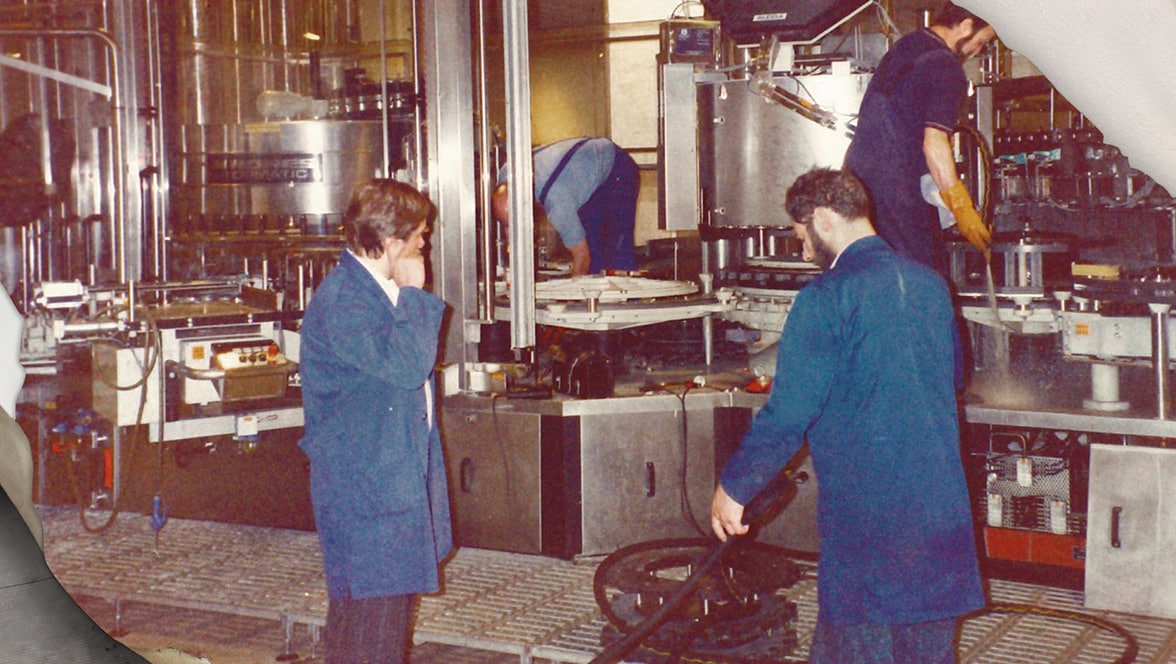

Back in 2015, Krones began training mechatronics engineers in Nairobi in cooperation with partner companies in the surrounding region.

In the past six years, a total of 31 trainees earned their Chamber of Foreign Trade certificate, which opens up the international job market to them. But many of the graduates didn’t even have to look for jobs elsewhere, because they were hired directly by Krones or the programme’s partners. “The programme gives us highly qualified employees with a lot of practical experience,” reports a proud Henning Post, who is responsible for business development and the training academy in East Africa.

But the programme initially had one big difference compared to its German equivalent: because there was no vocational school in this region at the time, “only” a two-year, purely practical training was possible at first. Since 2020, the training programme has finally been expanded to include the theoretical aspect. The foundation stone for the construction of the vocational school was laid in February 2020 and in October of the same year twelve trainees started the dual training as the first group – despite the coronavirus pandemic. Four of them have a mentoring agreement with Krones. Similar to the German model, theoretical learning at school and practical training in the company alternate in a three-month rhythm.

“The programme gives us highly qualified employees with a lot of practical experience.”

Henning PostBusiness Development and Training Manager

Henning PostBusiness Development and Training Manager

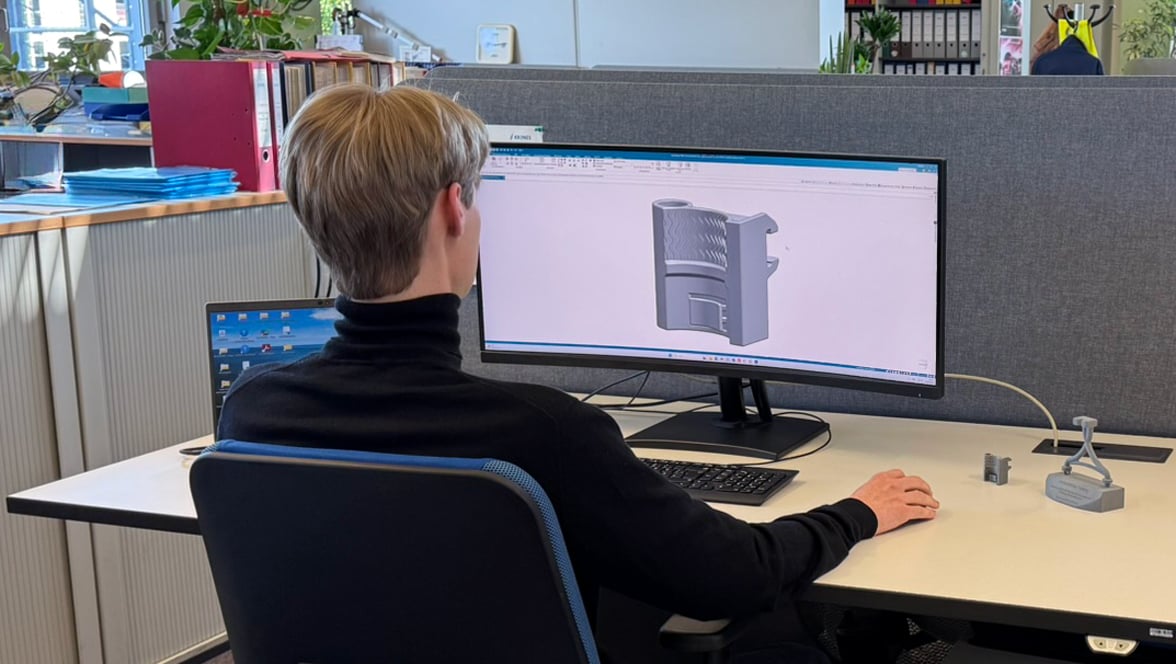

Practically ingenious

In order to give the mechatronics engineers a versatile training, the participants are taught a wide range of practical tasks, including work in the fields of electrics, inspection and filling technology. At the academy of Krones East Africa, the focus is primarily on training modules related to electrics: “The students learn how to handle all the tools needed when working with electrical equipment,” explains instructor Albert Kiio. "Our training content includes drilling and cutting metal, stripping and laying cables, as well as programming and implementing electrical circuits.” This requires a variety of technical training equipment and machines, which are all provided by Krones. “The generously equipped ‘toolbox’ includes a Krones line of standard equipment, simulation racks, oscilloscopes and docking stations for labelling and conveyor systems,” says Albert Kiio, beginning a list that could probably go on longer.

In order to be able to accurately and completely pass on the knowledge of how to use all these tools and machines, the instructors and vocational school teachers also receive special support. “They all spent a few weeks in Germany and participated in further training directly on site at our plants in Neutraubling and Nittenau. In this way, they got to know the dual training as we practice it in Germany at first hand, so that they have then been able to implement it themselves in Nairobi,” explains Henning Post. “In the end, everyone benefits from this approach: the teachers and instructors are optimally prepared, and can thus train specialised yet holistically schooled technicians, who will have countless possibilities on the labour market. But, of course, we are most pleased if they want to work for Krones afterwards.”

“The students learn how to handle all the tools needed when working with electrical equipment. Our training content includes drilling and cutting metal, stripping and laying cables, as well as programming and implementing electrical circuits.”

Albert KiioInstructor in Nairobi

Albert KiioInstructor in Nairobi

Aside from the tight teaching programme, the students and their instructors meet for picnics, go on boat trips or compete in sporting contests. “These joint activities build team spirit and promote respectful togetherness. In addition, small award ceremonies after the competitions reward the winners, which can be an important motivation to get even better,” Albert Kiio explains with a wink.

Dual training has quickly made a name for itself in Nairobi. More and more young Kenyans are applying for one of the coveted training slots. “I knew straight away that this type of training would be perfect for me,” says Mary Maina. She successfully completed her training in 2019 and has since been working at Krones as a service engineer for inspection technology – and with great enthusiasm, as she describes: “I feel well prepared for all the challenges and tasks I’ve to deal with and can hardly wait to see what else will be in store for me.” Henning Post also points out that the training programme puts Krones East Africa in a unique position in Kenya and the surrounding region since they are the only provider of this type of program to promote local talent. Furthermore, it also contributes to society by introducing more gifted young people to the industry and giving them a solid foundation for a career as highly competent technicians for the sector.

“I feel well prepared for all the challenges and tasks I’ve to deal with and can hardly wait to see what else will be in store for me.”

Mary MainaService engineer for inspection technology

Mary MainaService engineer for inspection technology

Learn more about the training programme in Kenya in this video:

Be part of our team

If you would like to become part of the global Krones network, it’s worth taking a look at our job advertisements – or simply write an unsolicited application.