Logan Plant, the founder of Beavertown, was first inspired by the beers from his home region, the Midlands, which are known for their great beer heritage in the UK. At the age of 20, he dreamed of starting a brewery. But that got side-lined in favour of touring as a musician for 10 years. Eventually, he came back to that dream and, together with his wife, opened a brew pub in East London, where he brewed his own beers in the kitchen – about 800 litres a batch, once a week.

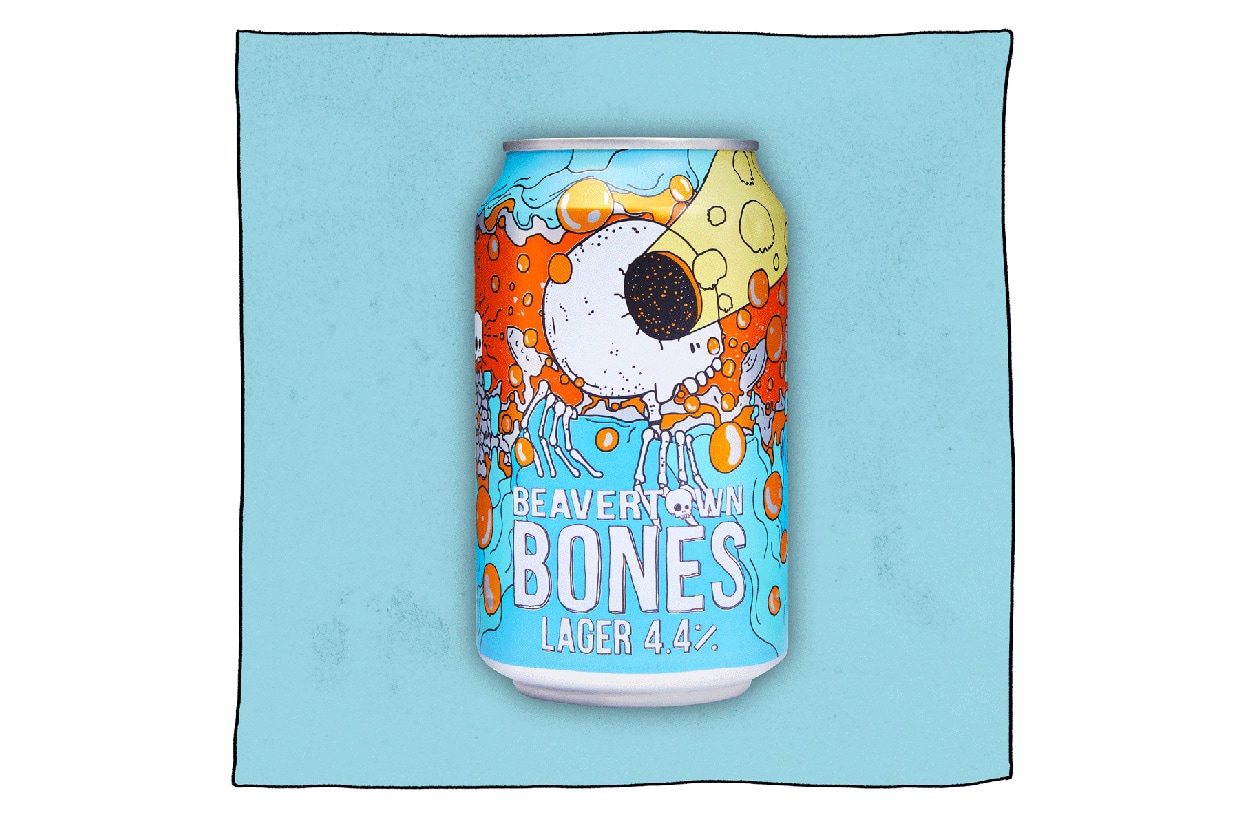

Now, ten years later, what started as a small project has become much bigger: Beavertown has several brewery locations in London, including a microbrewery in the Tottenham Hotspur stadium, where they supply their beers to the fans of the club. The latest expansion came in 2022, with the commissioning of their newest and largest brewery, a 150-hectolitre fully automated Steinecker setup. Here, they create a new, innovative beer every month – in addition to their core range, which is available all year and consists of seven beers, and their barrel programme where they age and mature beers in wine barrels.