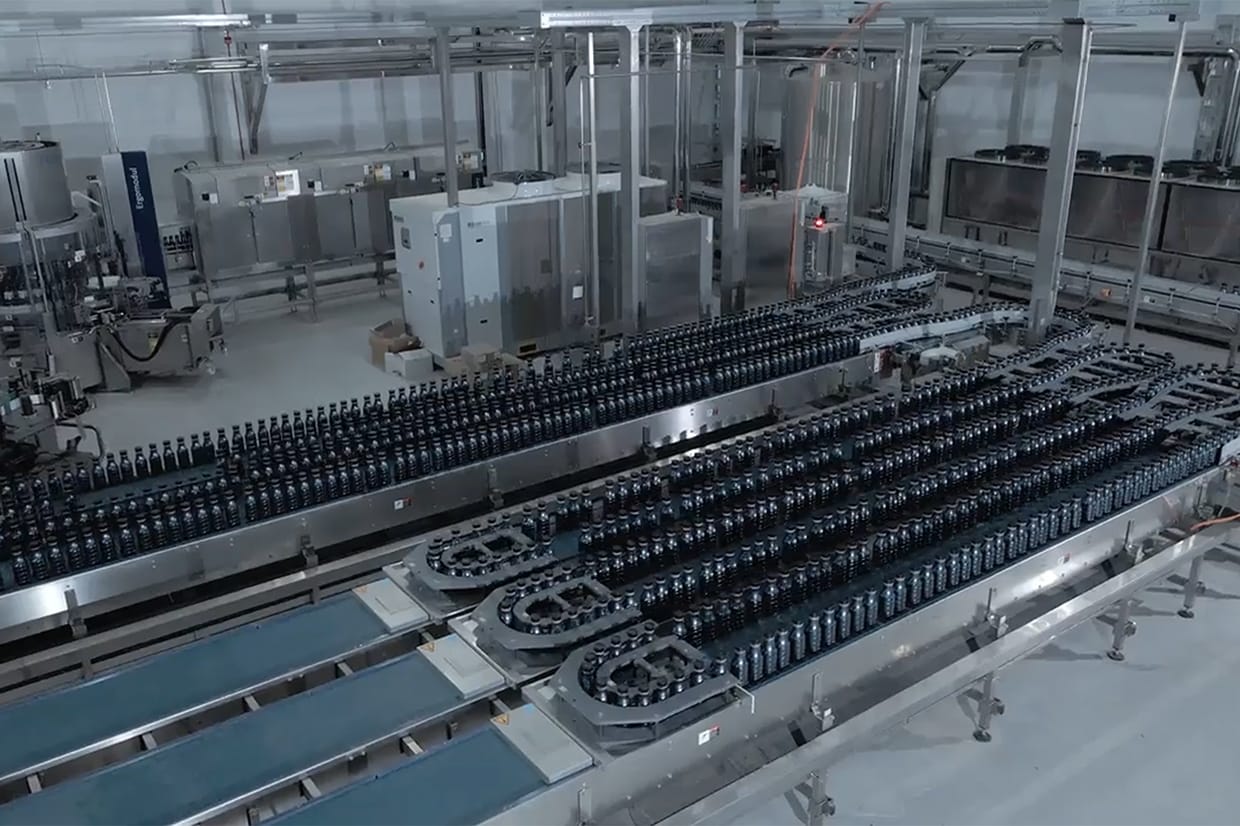

With consumers’ growing thirst for healthier beverages that contain no added preservatives, one technology in particular has gained more and more prominence in the market: aseptic filling in PET bottles. This is precisely the solution Krones supplied to Vinícola Panizzon in Brazil, in the form of a complete aseptic line.